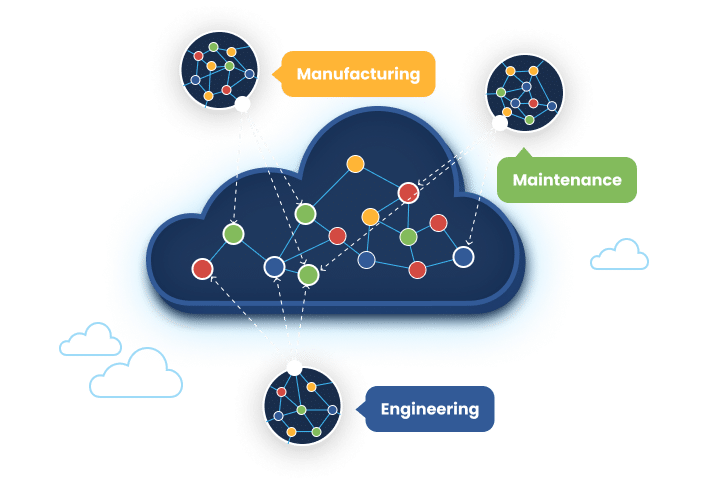

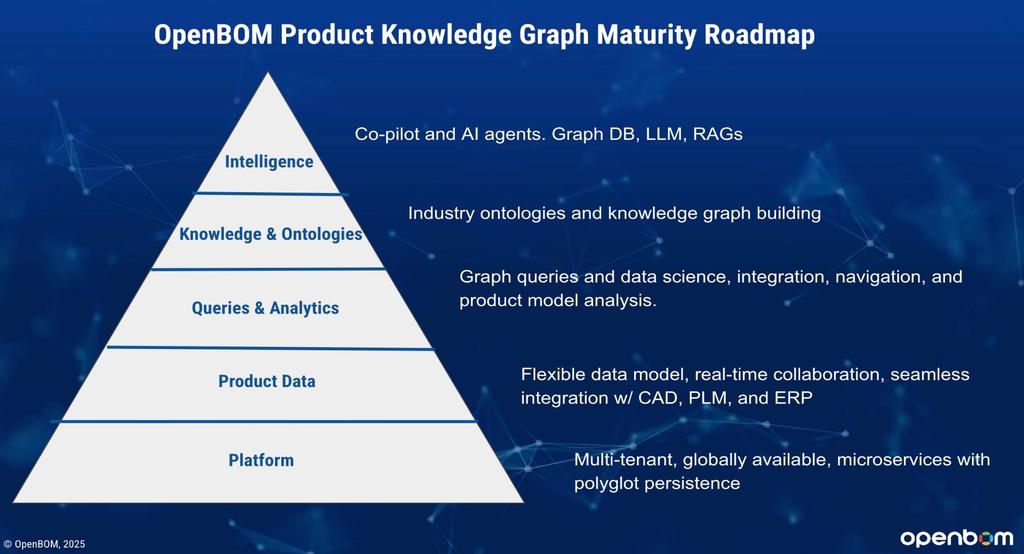

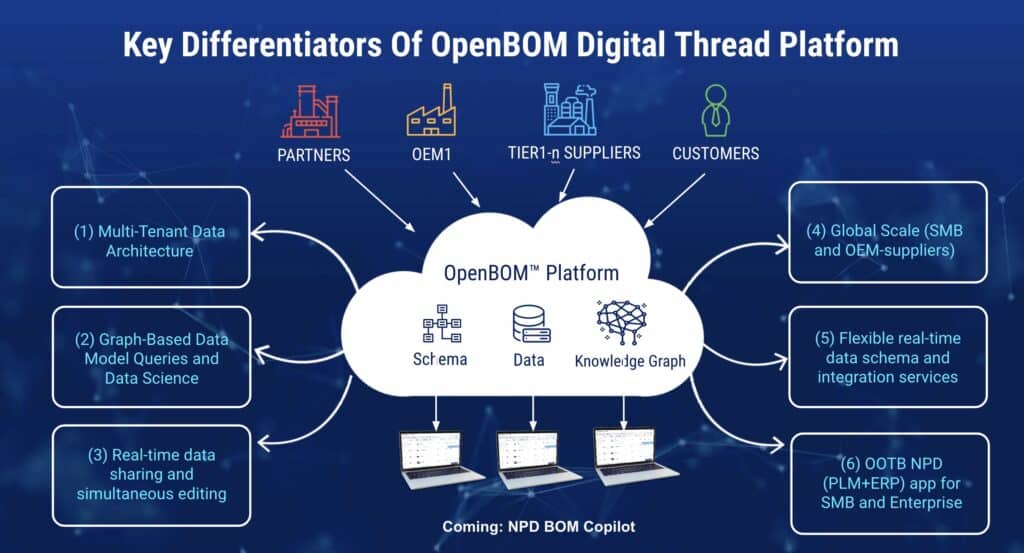

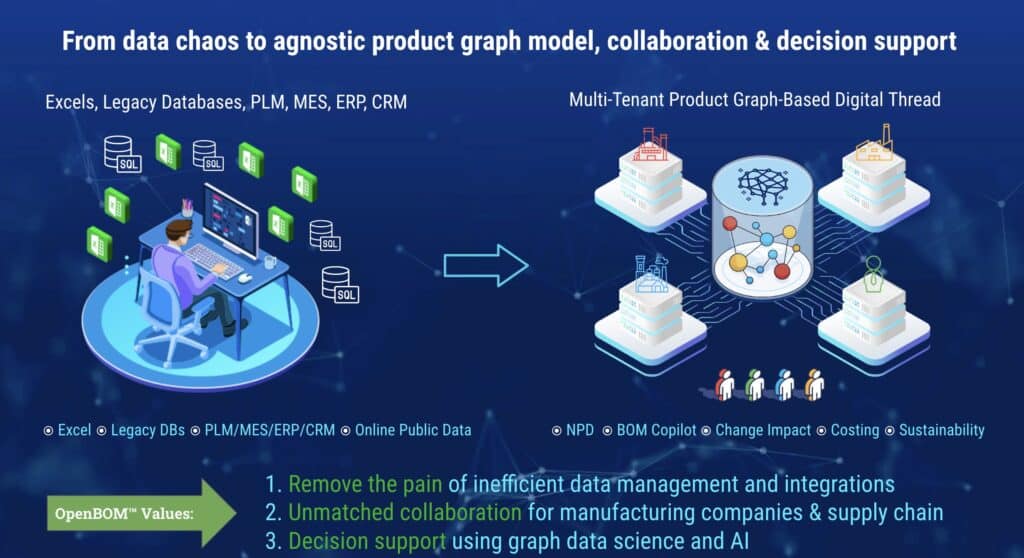

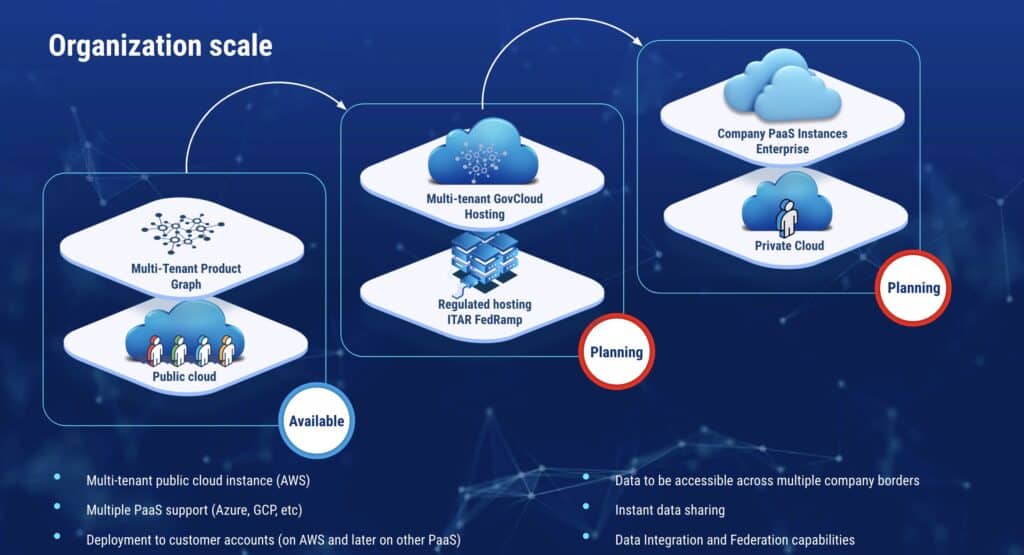

OpenBOM provides a global digital thread SaaS platform that includes elements of product data management (PDM), product lifecycle management (PLM), and enterprise resource planning (ERP) to help industrial companies to collect data, organize information, collaboration, and lifecycle management processes.

OpenBOM plays the role of an integrated PDM/PLM/ERP solution for SMB/SME organizations and provides a system of engagement and intelligence for large enterprise companies.

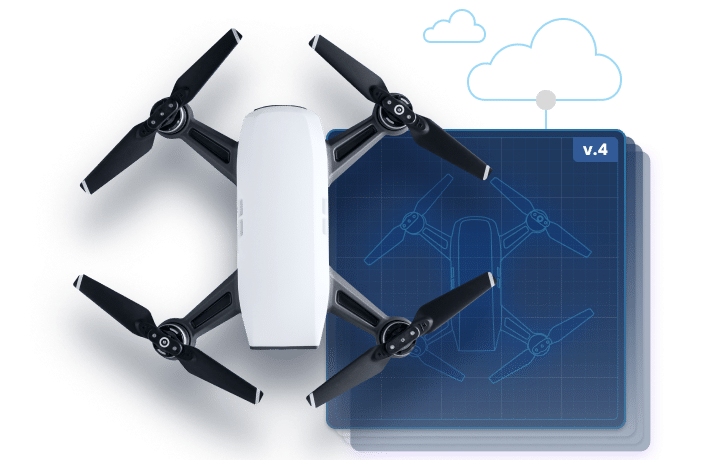

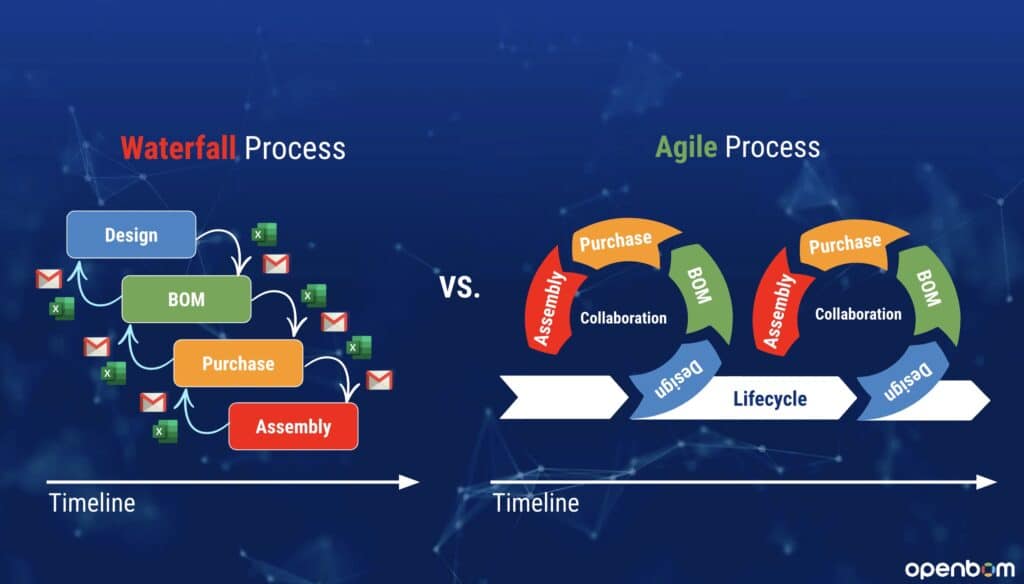

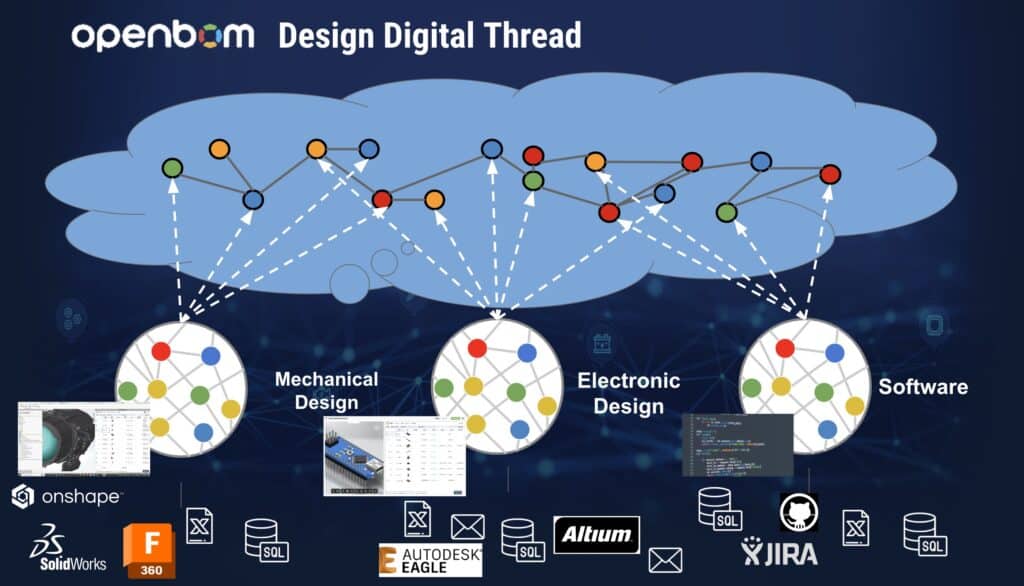

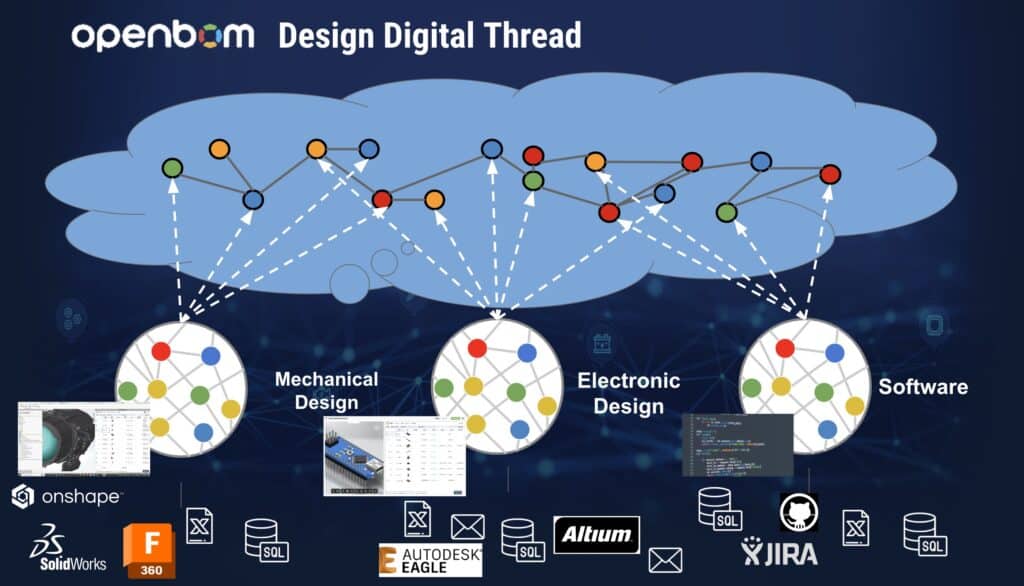

OpenBOM provides a digital thread support for your multi-disciplinary design digital thread by aggregating data coming from multiple design (CAD) systems and services.

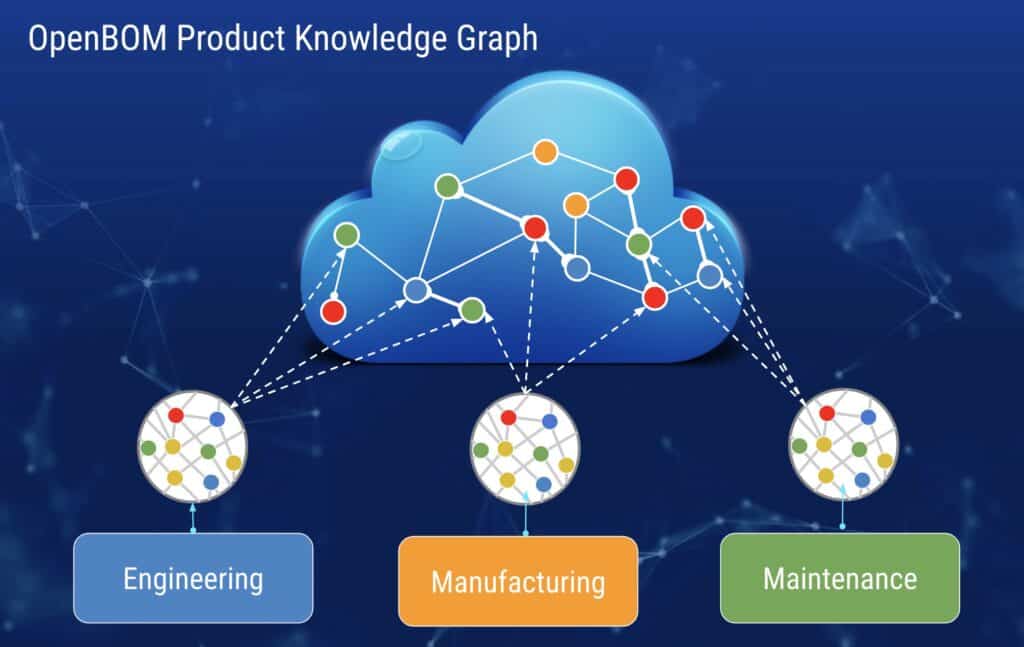

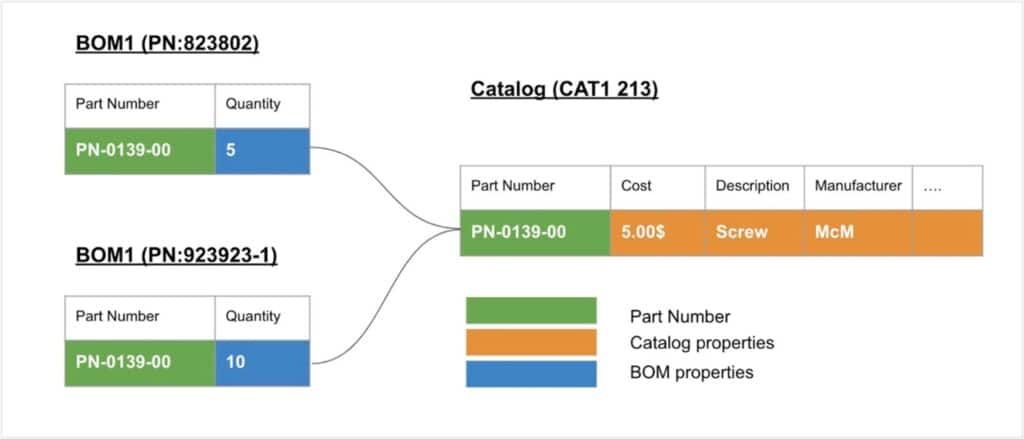

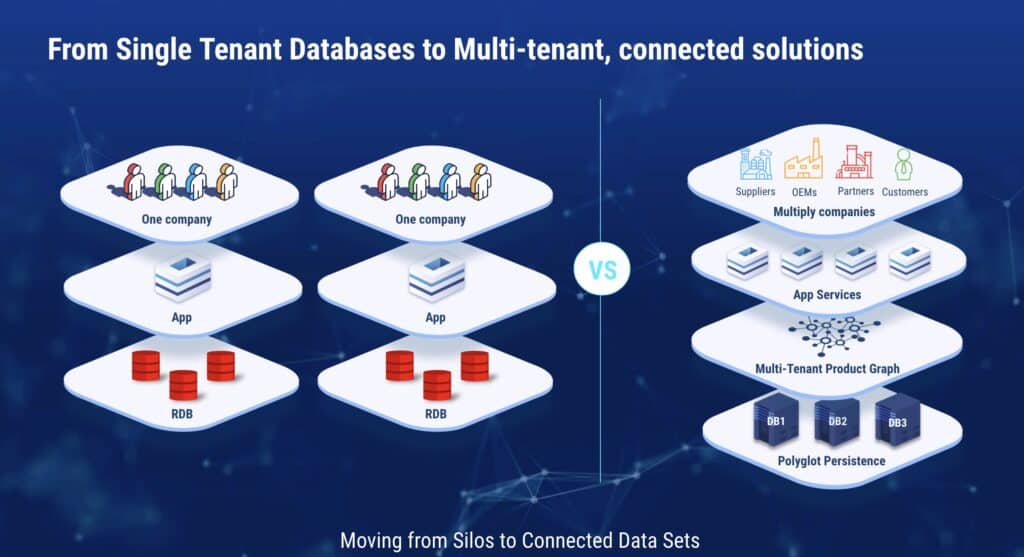

The foundation of the OpenBOM platform is distributed multi-tenant data platform capable to manage product data and all related pieces of information (engineering, manufacturing, supply chain, procurement, financial, etc.)

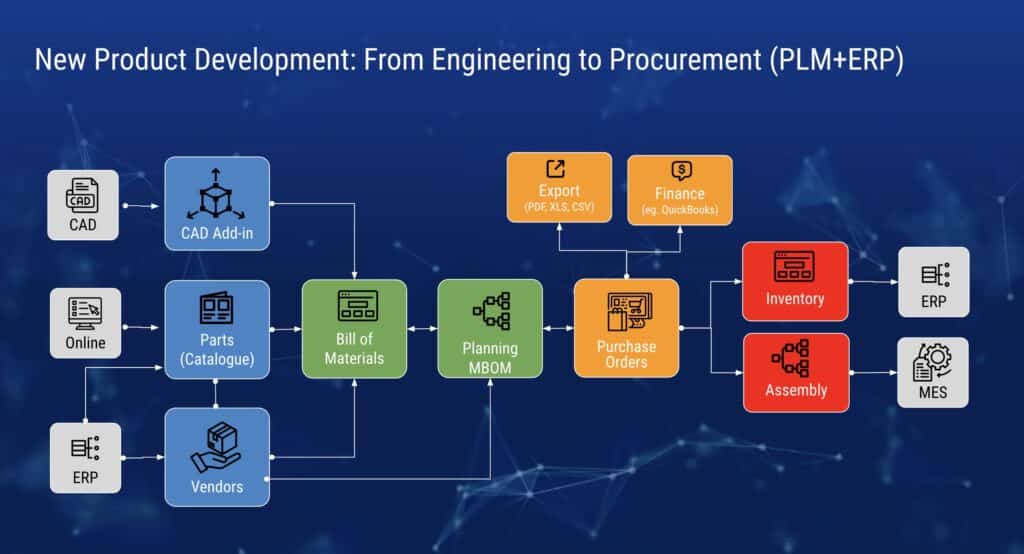

OpenBOM is integrated with all engineering (CAD) systems and, if needed, with other PDM, PLM, and ERP systems.

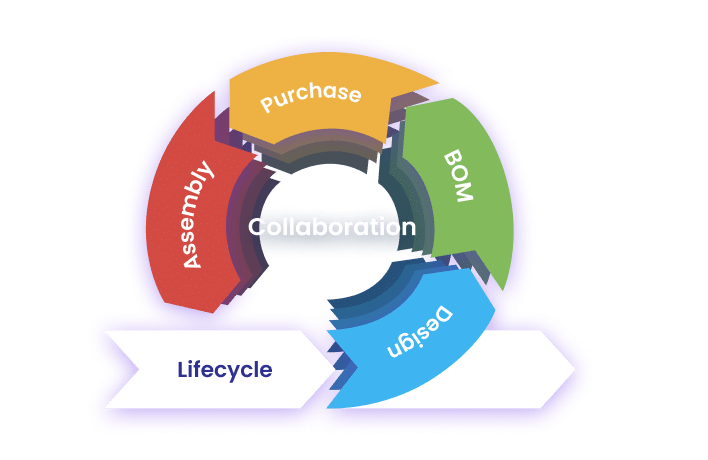

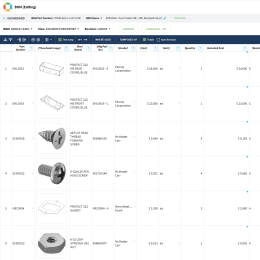

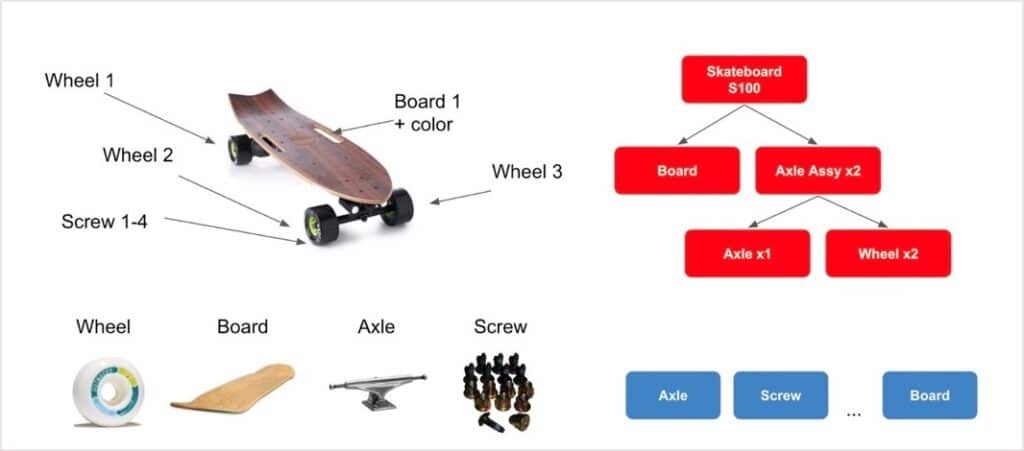

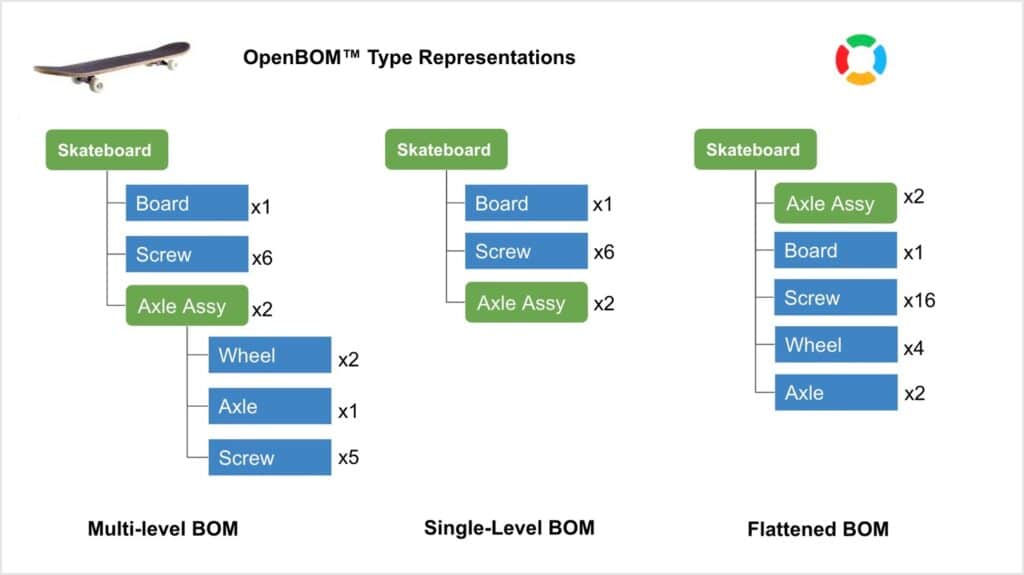

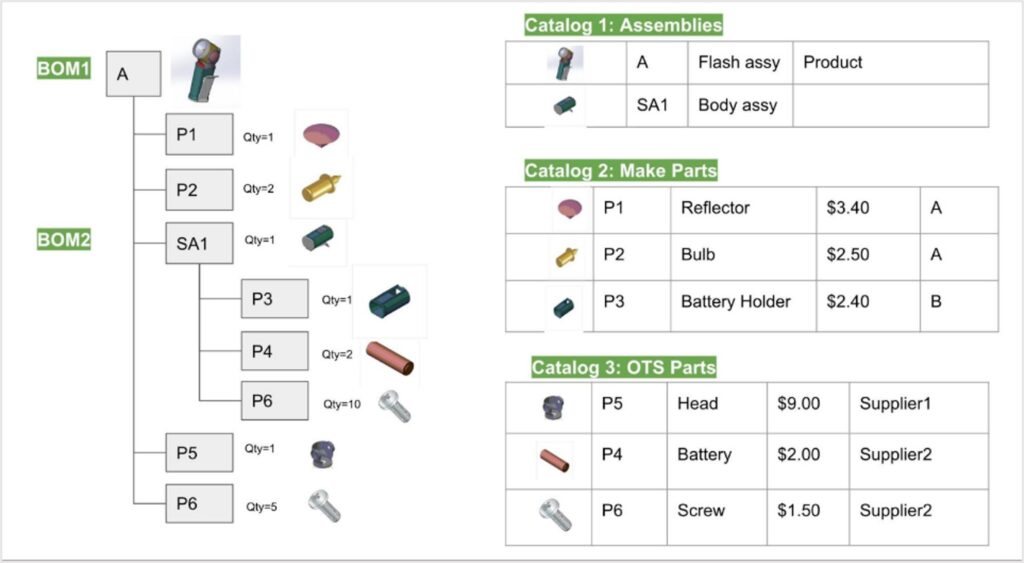

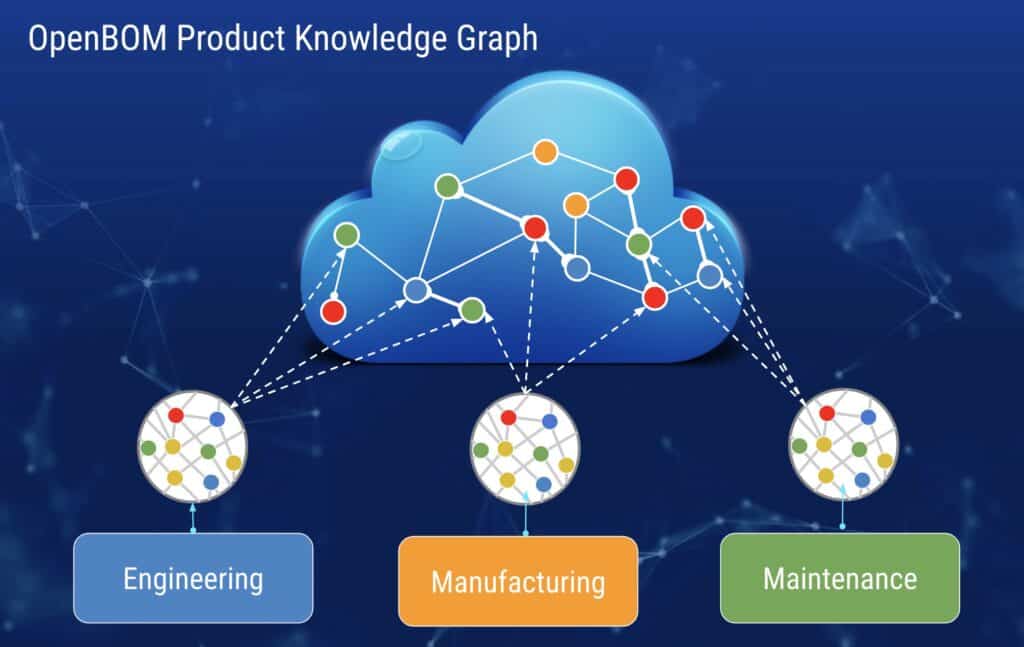

The core of the platform is a flexible data model capable to manage product information, product structure (BOM), and all relationships of Bill of Materials with other systems, products, vendors, contractors, and suppliers. By doing so, OpenBOM builds a global BOM knowledge graph and uses it as a foundation of data management.

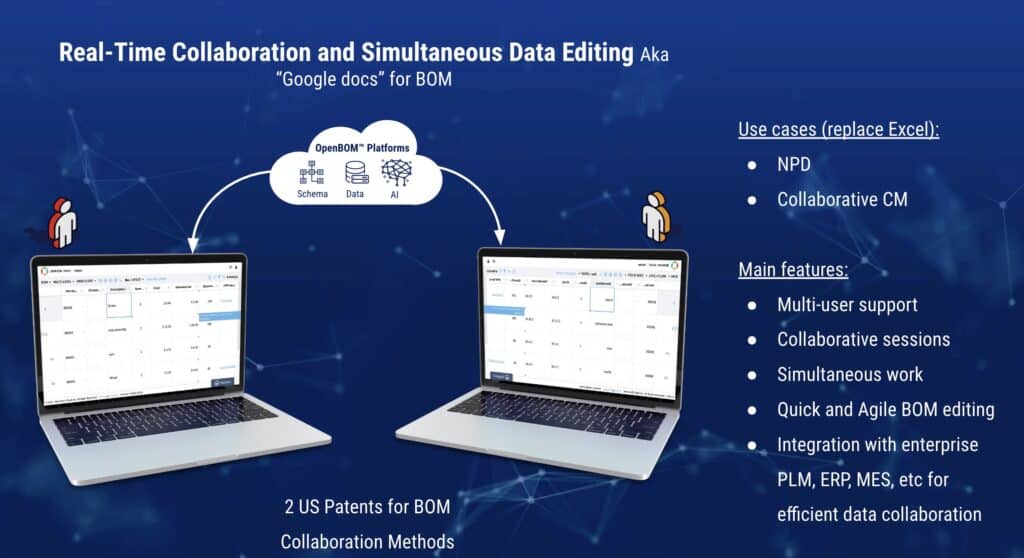

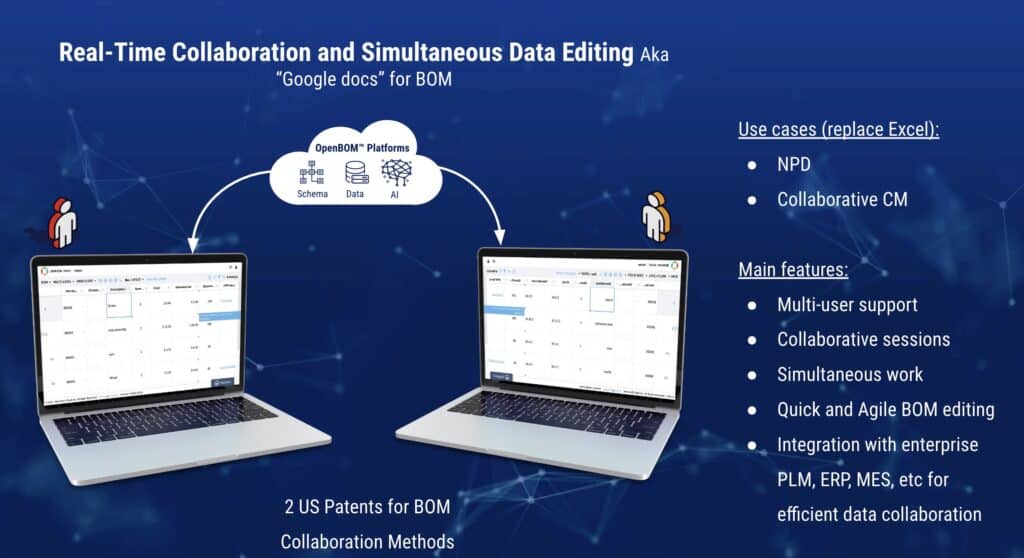

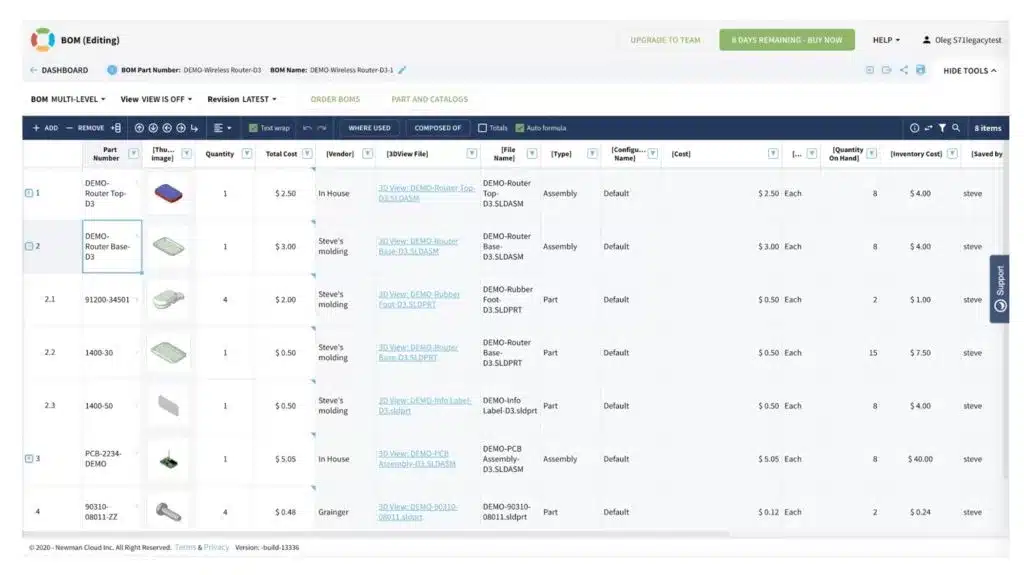

On top of a sophisticated data management platform, OpenBOM provides a very simple and intuitive user experience with the foundation using familiar spreadsheet-like editing paradigms and collaborative tools.