What is it?

In today’s business environment, manufacturers must optimize the supply chain, in order to keep production levels growing.

One way to increase efficiency and reduce costs is to multi-source products in the supply chain. Through effective product sourcing, which is the process of finding quality products to sell through reputable suppliers at the most affordable price, manufacturers can improve their overall competitiveness. In turn, sourcing components is one of the most important parts of product development.

Many decisions need to be made during the product sourcing stage of the supply chain. For example, you have to consider whether each component or sub-assembly can be manufactured internally or needs to be purchased externally from a supplier.

Product sourcing is becoming increasingly complex as sensors, software, and electrical components are becoming essential to product differentiation and cost.

It is especially important to be able to maintain your sourcing strategy, in order to provide the right balance of vendors/sources at different stages of product development and production, such as prototyping and production, etc.

Why do you need it?

Managing product sourcing digitally is essential for your business to cope with shorter production cycles, a competitive market, and globally dispersed teams and suppliers.

Collecting and managing supplier information can be a tedious manual task and runs the risk of human error. By digitizing your vendor management, your team will have access to vendors, vendor data, and vendor parts in a central hub. This will enable your team to effectively plan component sourcing and efficiently manage vendor lists and sourcing approvals.

Vendors can also be organized by the goods that they provide, making it easier to search for the right supplier.

Why is OpenBOM different?

Instead of managing your vendor information in a difficult-to-navigate Excel spreadsheet, vendors can easily be integrated into OpenBOM with our “Vendor Lists” functionality. A vendor list contains all of the important data regarding the companies that you use as a source of standard parts (contractors and suppliers). Such lists are very flexible and easy to navigate.

As OpenBOM is cloud-based software, everyone in your company (or those that you give reading permissions) has access to vendor information. This improves efficiency across the team since sharing vendor information is made simple. You can find all vendor information from your company’s “Vendor List”. Alternatively, the vendor of each item can be found within your catalogs and/or BOMs if a vendor property has been applied.

Furthermore, OpenBOM offers collaborative capabilities with multiple options to assign a vendor. For example, in catalog, in an order or purchase order.

OpenBOM simplifies the sourcing process by allowing you to send purchase orders directly to the vendor from within the platform. Similarly, OpenBOM enables you to source from multiple suppliers. This is something that is essential nowadays, to decrease costs and increase efficiency.

How does it work?

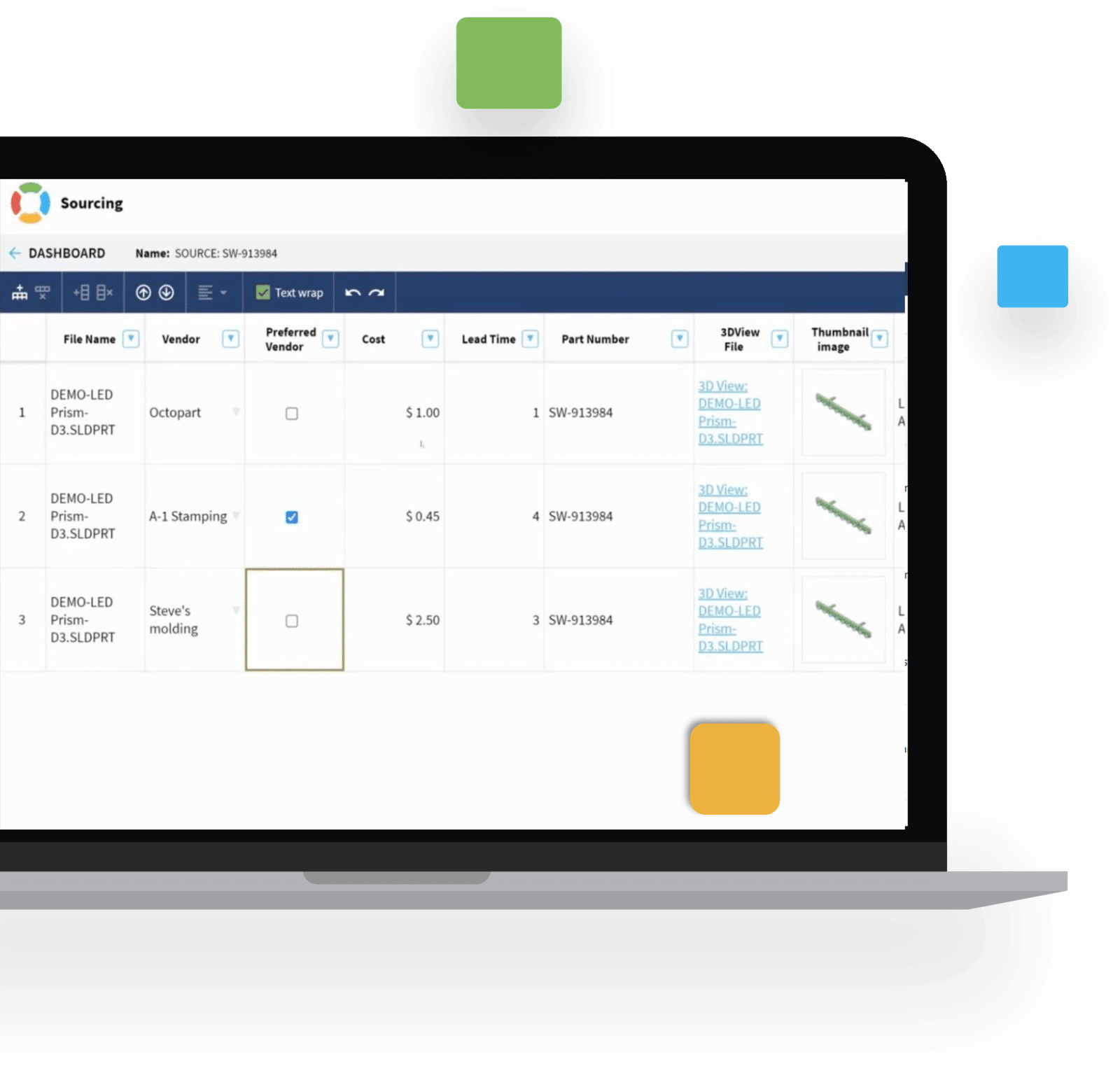

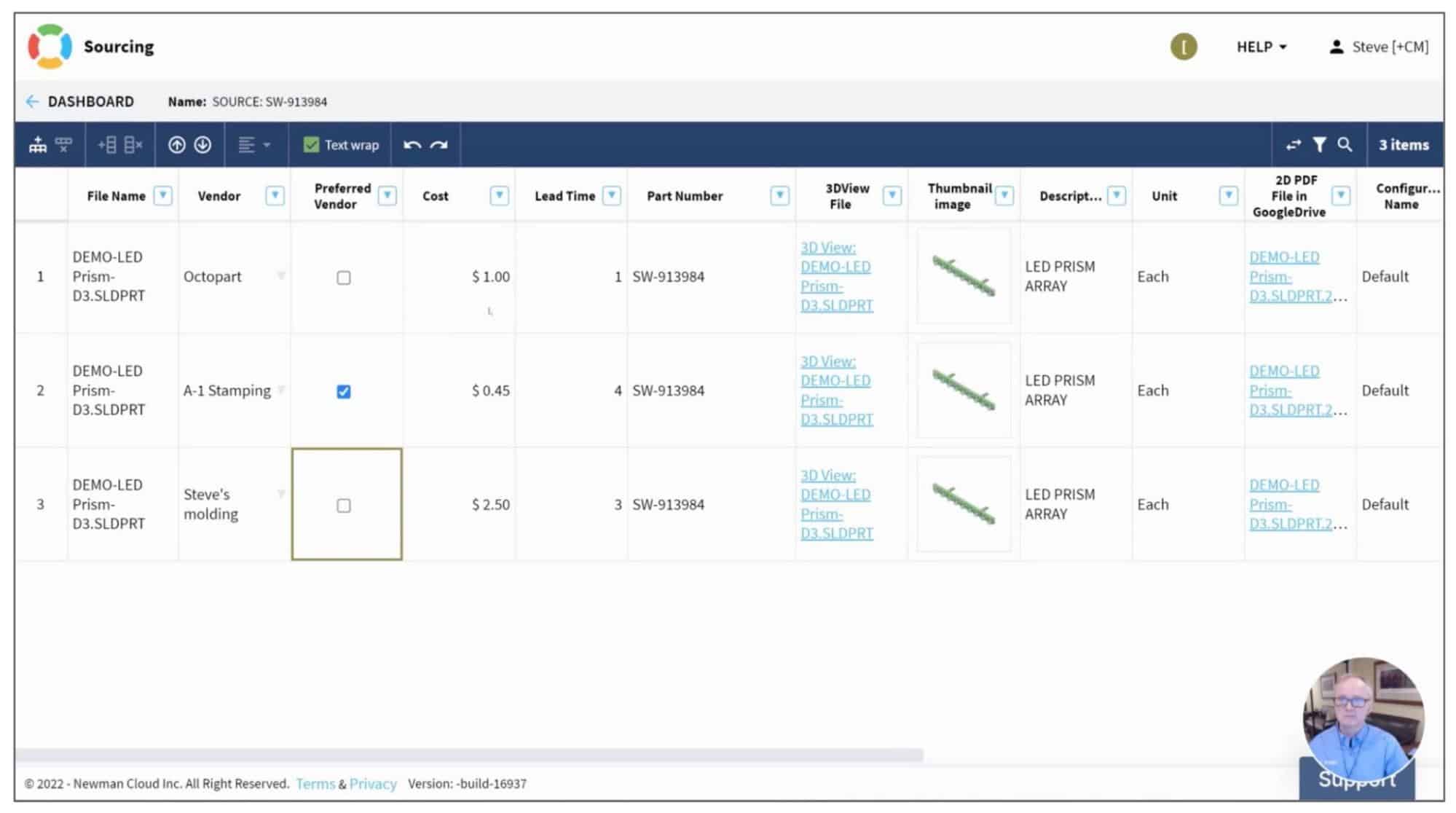

From your OpenBOM dashboard, you simply need to access the “Vendor Lists” section from the “Production Planning” tab. Here you can add, modify, and remove your vendors. Now, you can add these vendors to individual items by adding a “Vendor Name” property and selecting the vendor from the drop-down list. This change will be automatically applied wherever this item has been used.

You can directly send a purchase order to a vendor from inside a BOM by clicking on the “Orders” button at the top of the page. From here, you can update any current orders and create new orders for each item included in the selected BOM.

Through the new sourcing flyout, you can add and change sourcing options from the sourcing objects grid. The sourcing objects grid is a fully flexible data model that allows you to define all attributes and characteristics of the supplier. Furthermore, if there are multiple sourcing options for an item, you can use a preferred flag to define a preferred supplier in all BOMs.

Nonetheless, it is also easy to switch between suppliers and create multiple orders from different suppliers at the same time.