Let’s talk about the part number system today. Every engineering team and manufacturing organization needs a clear, consistent part number management strategy. But here’s the catch — most companies assume that strategy will just magically sort itself out. Spoiler alert: it won’t.

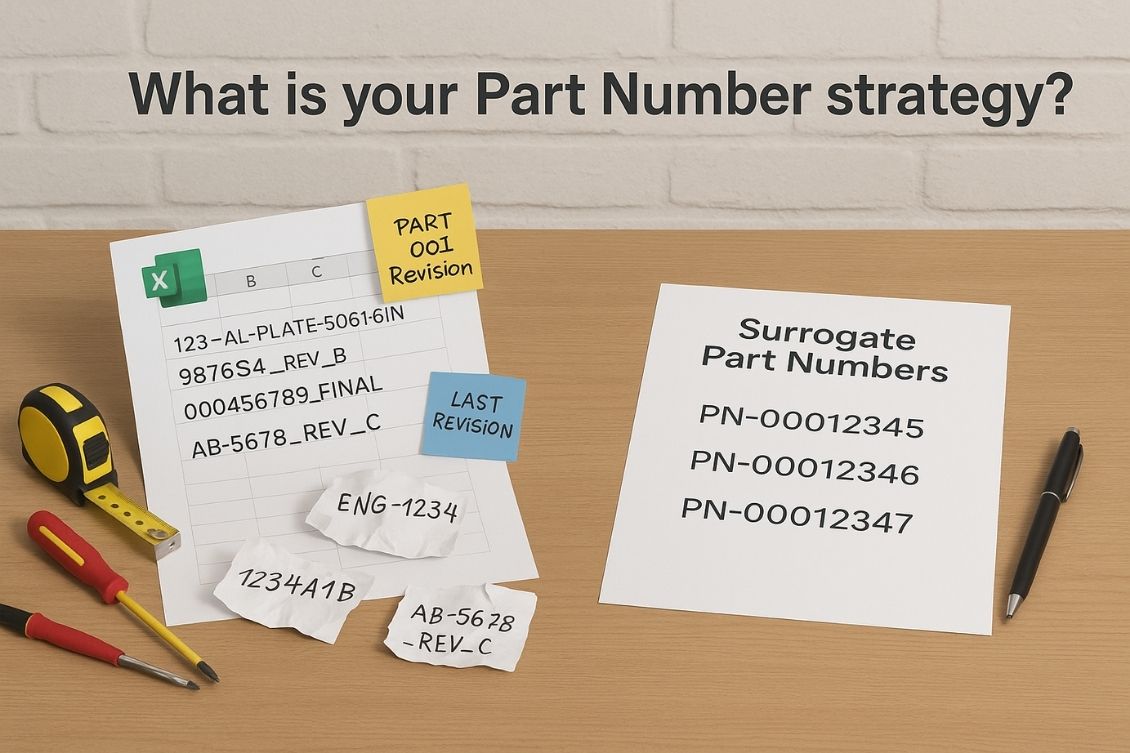

It’s not uncommon to see product development kick off without any real agreement on how to identify parts, assemblies, or even basic components. The result? A confusing mess that slows everyone down. If you’ve ever found yourself in a meeting that suddenly spirals into a heated debate about part numbering scheme, you’re in good company. It happens all the time and for a good reason.

Part numbers are more than just codes. They are the digital backbone and one of the business tools for efficient product development and manufacturing processes. Every time a part is designed, purchased, assembled, or serviced, the part number is the reference that links the entire lifecycle together. It connects your CAD system to your BOM, your BOM to your ERP system, and your team to your vendors and, eventually other systems.

At OpenBOM, we’ve seen firsthand how crucial this topic is. One of the very first challenges business systems face when setting up a product data management system is how to handle part numbers. In fact, many teams get stuck before they can move forward because this one decision has so many implications. That’s why developing a part numbering scheme is not only important – it’s essential.

In this article, we’ll explore what part numbers are, why unique part numbers matter, indentify common philosophies and data entry errors, how to design your own part numbering system strategy, and how OpenBOM can help make business processes much easier.

What is a Part Number Management, and Why It Matters

What is manufacturing part number? A part number is a unique identifier assigned to any item that is used in the design, production, or support of a product. This includes physical parts, subassemblies, materials, consumables, and even documents or drawings for effective inventory management. Even more, labor, documentation, packaging, etc. — everything can be considered as an item with Product Numbering.

The value of a decent part number structure lies in its ability to serve as a consistent reference. Unlike descriptions, which are often ambiguous or prone to variation, part numbers provide a clear and unchanging primary identifier for each right product. When evolving proper management, a part numbering system can eliminate confusion, reduce errors, prevent conflicts, and optimize communication between various industries, teams, systems, and suppliers.

When part numbers are inconsistent or have incorrect parts, the consequences ripple throughout the organization: duplicated purchases, miscommunication between engineering and procurement, delays in production, and costly errors in the field.

In short, a good part number system is a small investment with a big return- it helps build reliable data structures that support traceability, automation, and cross-functional collaboration.

Data Entry: Significant vs. Non-Significant Part Numbers

There are two main schools of thought when it comes to how part numbers are designed: significant (also known as intelligent) and non-significant (also known as non intelligent part numbers).

Intelligent Part Numbers

In this approach, the part number itself makes sense. Let’s analyze a part number example. You might use a code like ASM-AL-6061-6IN to represent an aluminum assembly made from 6061 alloy in a 6-inch size. These formats are often preferred in smaller or legacy teams where parts are identified manually or visually.

The advantage of such number formats is that more than one person can often understand something about the part just by reading its number. It helps when sorting or filtering parts without needing to look up additional details. So, it saves time.

However, this logic starts to break down as the supply chain grows or changes. If the material or dimensions change, do you change the intelligent part number? What happens if two teams interpret the embedded codes differently? Over time, intelligent part numbers become harder to maintain, more error-prone, and a barrier to automation.

Non Intelligent Part Numbers

By contrast, non intelligent part numbers are designed to act as pure unique identification codes, with no internal logic or meaning. Something like PN-00012345 tells you nothing about the part’s shape, size, or function — but that’s the point. All meaningful information is stored separately as additional details in your part number management software or system. So, the identification process may be time consuming.

This approach is highly scalable and system-friendly. It reduces human interpretation errors and supports automation across part number generator software platforms. With modern databases that can display more detail about all necessary vendor part number metadata with multiple dimensions instantly, there’s little value in embedding logic into the number itself.

At OpenBOM, we strongly recommend using non-significant part numbers. They offer simplicity, flexibility, and stability — qualities that matter most as your business scales.

How to Develop a Company Part Number Strategy

Defining a part number strategy is one of the most critical early steps in setting up your digital product data environment. It requires input from engineering, manufacturing, procurement, and IT — and the decisions you make will shape how data flows through your organization for years to come.

Here’s a structured, step-by-step engineering part numbering process your team can follow:

Step 1: Define Your Objectives

Start by asking why you need part numbering system in the first place. Is the goal to improve efficiency and traceability? Simplify communication across systems? Automate ERP and procurement processes? Different use cases may push your strategy in different directions.

Also, consider the systems involved. Will your part numbers need to flow across CAD, PLM, ERP, MRP, or other manufacturers databases? Understanding these interfaces will help you avoid design choices that create friction later.

Step 2: Choose Your Numbering Philosophy

Next, choose between non intelligent and intelligent part number system. While significant numbers may appeal to those who prefer human-readable codes, they are typically harder to maintain at scale. Non-significant numbers are simpler and integrate better with modern software like OpenBOM.

If you’re still unsure, ask yourself this: “Do we want to design a part numbering system that hundreds of humans can read, or one that machines can manage reliably?” The long-term answer usually points to surrogate, non-significant part numbering system.

Step 3: Define a Clear Format and Consistent Length

Once you’ve chosen your philosophy, standardize the sequential number structure. This includes decisions like:

- Prefix rules: Use simple serialized suffixes to differentiate types (PN- for parts, ASM- for assemblies).

- Certain length: Ensure a consistent part number length — typically between 6 and 8 characters. The number length should be short enough to manage, long enough to scale.

- Character rules: Avoid underscores, leading zeros, or ambiguous characters like O vs 0 or I vs 1. Use only certain fonts that provide clarity.

Having a consistent numerical order in serial numbers prevents confusion and simplifies data entry and organization across different software.

Step 4: Keep Revisions Separate

A common mistake is to embed revision history into the part number — for example, using 123456_REV_A. This blurs the line between the product identity and versioning and creates confusion in existing systems that already track revision as a separate field.

Instead, let the part number refer to the product itself, and use a distinct revision field to identify and track changes. This makes lifecycle business management, traceability, and integration much easier to manage.

Step 5: Decide How Numbers Are Assigned

Will numbers need manual data entry, or automatically by software? Will different teams (engineering vs purchasing) use different or same length number blocks? Will you need to preserve certain ranges for legacy parts?

Deciding this upfront helps avoid conflicts later — and makes onboarding practices of each single person faster and manufacturing specifications much easier for new team members.

Step 6: Document and Share the Rules

Once your part numbering scheme is defined, document it in a clear internal policy. Share it with all relevant teams and manufacturers and make sure it’s reflected in onboarding, training, and system configurations.

Part numbering process works best when it is predictable and consistently applied — so communication is key.

Step 7: Use a Digital System (e.g. OpenBOM) to Enforce the Strategy

Even the best part numbering scheme can fail without the right tooling for efficient data entry. Manual entry in spreadsheets or siloed systems often leads to number duplication and inconsistency.

A cloud native PLM system like OpenBOM can automate number generation, validate uniqueness, and keep your catalog organized — all while integrating seamlessly with CAD and other tools your team already uses.

How OpenBOM Supports Part Numbering

OpenBOM is designed to help you implement a robust and scalable manufacturer part number strategy — whether you’re reusing existing numbers or starting from scratch with new ones.

Support for Both Reuse and Generation

OpenBOM gives you flexibility. If your business company already has a part numbering system in place, you can import and manage existing part numbers across catalogs. If you’re starting a new system or looking to automate best practices, you can use number generated by OpenBOM based on configurable templates and rules.

This means you can gradually migrate to a better system — without disrupting existing manufacturing processes.

Integrated Part Number Generators for CAD Add-ins

OpenBOM’s CAD integrations (SOLIDWORKS, Autodesk Fusion, Inventor, Altium, and others) include built-in part number generators. Once your part numbering scheme is set up in OpenBOM, it can be applied consistently as engineers export parts from CAD. There’s no need to manually assign numbers or worry about mistakes — OpenBOM ensures every part gets a valid and unique identifier.

This dramatically reduces friction and enforces company standards directly at the source.

Catalog-Based Schemas and Uniqueness Control

With OpenBOM, you can define different part number schemas per catalog. This allows engineering items, purchased components, and tooling to follow different formats or ranges while still being governed by the same system.

OpenBOM also ensures manufacturer part number uniqueness across catalogs and will alert you if duplicates are detected, helping you maintain data integrity.

Built-In Duplicate Report

One particularly useful feature is OpenBOM’s duplicate part number report. This tool scans your catalogs to identify items with the same part number — especially helpful after importing BOMs from Microsoft Excel or CAD systems.

We recommend running this report periodically to keep your data clean and avoid conflicts that could affect purchasing or manufacturing.

Frequently Asked Questions

Q: What is manufacturing part number?

A: A unique ID assigned to a part, component, or item used in design, production, or service.

Q: What’s the difference between a part number and a revision in inventory management?

A: The part number identifies the product. The revision tracks which version of that product is currently used.

Q: What is a significant part number?

A: A code that includes embedded meaning — like size, material, or function. Useful for humans, but brittle over time.

Q: What is a non-significant part number?

A: A neutral identifier (like PN-00012345) with no embedded logic. All metadata is stored in system fields.

Q: Why avoid leading zeros and underscores?

A: Some systems remove or misinterpret these characters, leading to mismatches and confusion.

Q: Can I use letters in part numbers?

A:Yes, but avoid characters that look like numbers (e.g., O and 0, I and 1). Stick to a clear, readable format.

Q: Can I manage part numbers directly from CAD?

A: Yes. OpenBOM’s CAD add-ins generate and manage part numbers automatically based on your configured rules.

Conclusion

A well-designed part numbering scheme doesn’t just help your engineering team — it creates a foundation for the entire product lifecycle. From CAD to procurement, from prototype to production, your part numbers are the thread that holds everything together.

Avoid the trap of overthinking and over-encoding. Keep your part numbers clean, your data model rich, and your systems in sync.

OpenBOM gives you the tools and structure to get part numbering right — and to grow confidently from startup to scale.

REGISTER FOR FREE to check how OpenBOM can help you develop your improved Part Number strategy.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.