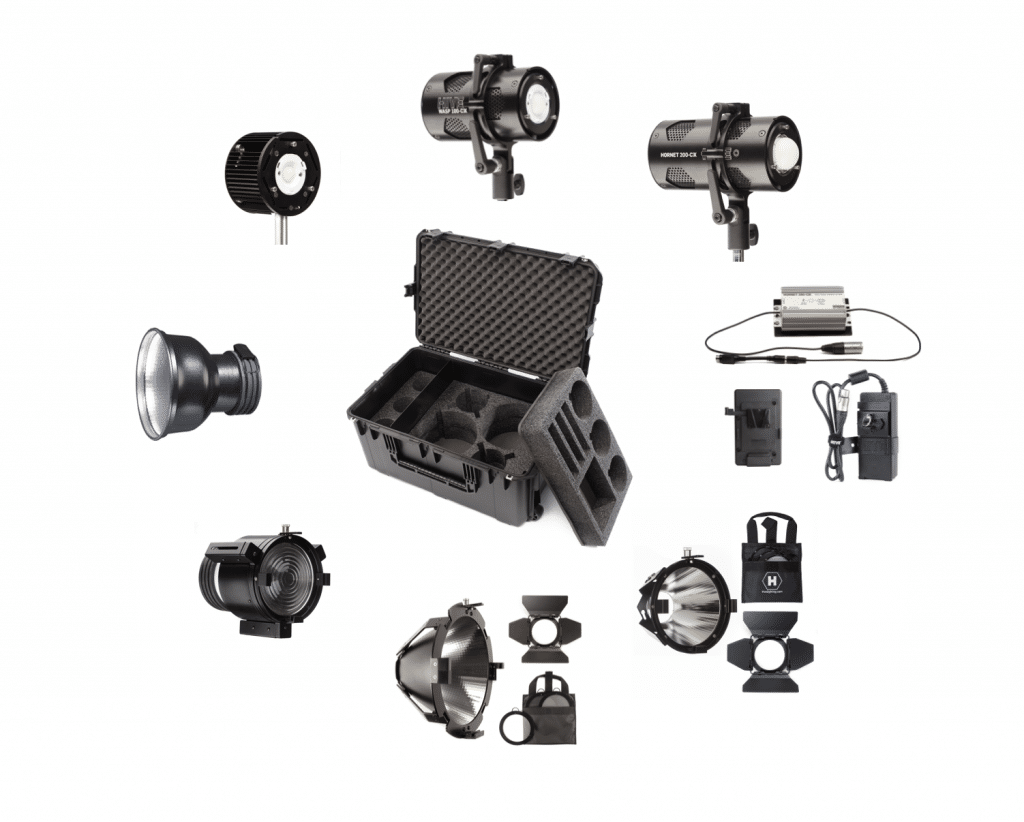

Located in the Art District of Los Angeles and only a few minutes from Hollywood California, OpenBOM customer Hive Lighting designs and manufactures some of the most technologically advanced film and production lighting in the world.

Hive can literally make anyone look terrific!

Mechanical Design Engineer and Hive Lighting OpenBOM Administrator Ivan Aristov recently took time out to help me understand their business and exactly how OpenBOM is benefiting them and their customers.

“OpenBOM is straightforward, easy to learn, and allows us to bring better quality, faster, to our customers”, Ivan explains.

Hive Lighting products are designed and Made in America, have a wide variety of component types and suppliers, and always look great when they arrive at the customer’s site.

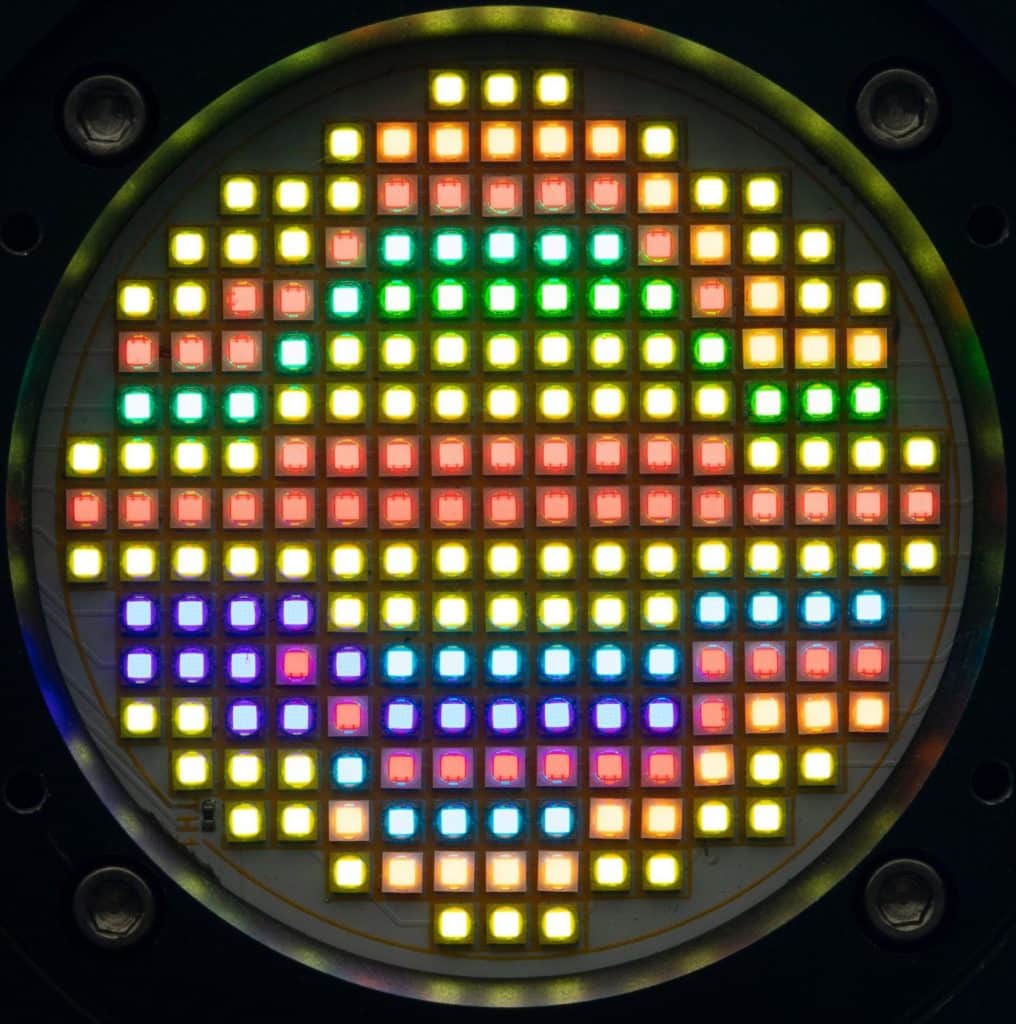

“Our lights are extremely high efficient and highly adjustable”, says Ivan. “Every product is designed specifically with our customer in mind.”

In 2020, Hive Lighting graduated from the Los Angeles Cleantech Incubator, a non-profit incubator created to accelerate the commercialization of clean technologies.

The company has received several industry awards for innovation and performance over the years in the professional lighting market.

As the Mechanical Design Engineer on many of the company’s products, Ivan is tasked with ensuring the product’s parts fit and look great, function properly, and come at a good price.

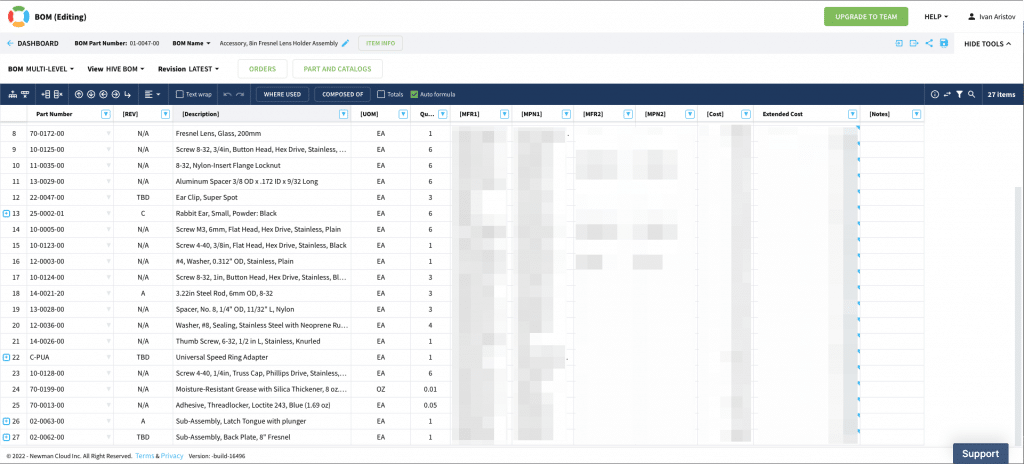

“Before OpenBOM, we managed all products in a single Google spreadsheet. We had one large document for ALL BOMs, dozens of tabs, some dupes, some tabs had several products…..”

“Another file was the Item master. I had to jump from one Google doc to another to ensure correct information when making even the smallest change.”

“OpenBOM brings organization and reliability to our data. It’s an interlinked system that allows changing details about one part in one place and it is updated in every BOM.”

As you can imagine, a modern lighting system has a lot of parts.

“We have thousands of parts and over 100 BOMs for our products in OpenBOM.”

“Maintaining our product BOMs used to be very time-consuming. We have a lot of common parts in multiple separate products,” Ivan says, “OpenBOM manages all the references and updates BOMs and items correctly, reduces errors, and saves us money. It is also very easy to track where a specific part or assembly is used – my favorite feature in OpenBOM”

“OpenBOM has reduced the time to build and maintain our Item Master and BOM by over 50%”, Ivan says.

Hive Lighting came to OpenBOM to organize their data but has quickly come to enjoy some of the more advanced features of OpenBOM.

“We like the way BOMs are revisioned and shared. Change reports are very helpful during the ECO process. The PDF export with a revision stamp and our company logo is easy and looks great!”

To learn more about Hive Lighting please visit https://hivelighting.com/

To learn more about OpenBOM please visit www.openbon.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.