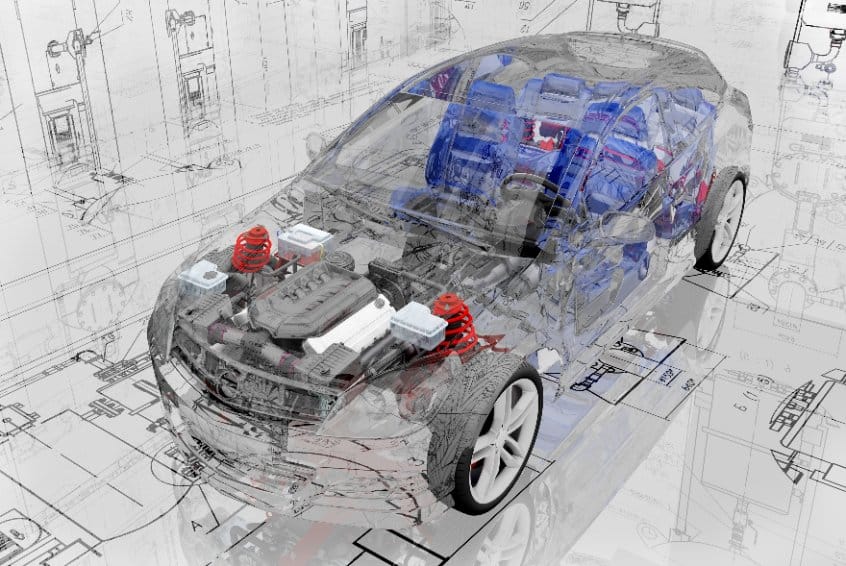

OpenBOM helps manufacturers of cars, components used in the automotive industry, and different transportation equipment. It includes managing the design lifecycle for CAD files, capturing full product structure, and managing changes.

The complexity of the automotive industry is skyrocketing. Companies need to have robust tools to design, manufacture, and maintain them. Manufacturing companies are looking for technology to help to improve efficiency and productivity and at the same time, to decrease the cost, and improve collaboration. OpenBOM helps to build a comprehensive product information model, and multi-level BOMs, perform cost calculation and analysis, and to enable real-time collaboration between teams, contractors, and suppliers.

Check What Customers Are Saying?

Tomcar

Jonathan Drori is the US company lead engineer and is part of the team responsible for the Tomcar series of vehicles.

“I absolutely love that OpenBOM lets me share accurate, complete BOMs with vendors, partners, customers, my colleagues in Israel, and so many more.”, says Jonathan. “It is great for my team and great for the company.”

Jonathan brought OpenBOM to Tomcar to improve and formalize the agreements the company has with manufacturing partners.

“Simply put, before OpenBOM, we did not have a final BOM that was accurate or easy to share”, he says, “We needed a full product BOM which OpenBOM delivered!”

Gaius Automotive

Managing Engineer Ray Chen says “the OpenBOM Access by View and Share by View functions are a powerful feature. It allows us to maintain one set of master data then strictly control who has access to it.”

In the simplest form, Gaius Automotive uses the OpenBOM Company and Team administration to control who can edit and who can view the Bill of Materials.

But it goes much deeper.

“Each department has its own View of the data, literally”, says Chen. “Department heads can see a broader scope of the design BOM and properties, while individual team members may get views of the data specifically tailored for them.”

Questum

Since its founding in 2014, Questum’s E-Mobility division, Atmovum, has been developing technology for sustainable urban mobility and OpenBOM is an important part of their success. Based in Monterrey Mexico, I recently sat down with José Elías Gallegos Arguijo (Elias), the company’s System Engineering and Electrical Integration lead, and Alfonso Gerardo Porras (Alfonso), their Product Structure Engineer, to learn more about the specifics of just exactly how E-Mobility designs and produces products dedicated to this space and where OpenBOM fits into their process.

“Our primary product is medium-duty truck conversions from diesel to electric,” says Elias. “We produce a platform to convert from diesel to electric.”

“Our product is complex”, explains Elias. “As our company and offerings grew, management of all these parts was becoming a burden. We had started with Excel and quickly realized that was not going to scale.”

“We needed something else, we were moving to Onshape cloud-CAD and we wanted a manufacturing planning partner product that did not break the bank,” says Elias.

“OpenBOM was a natural fit, tight Onshape integration, great manufacturing features, and it blended right into our commitment to cloud.”

Learn more about what OpenBOM can do.

Read more OpenBOM stories on G2.