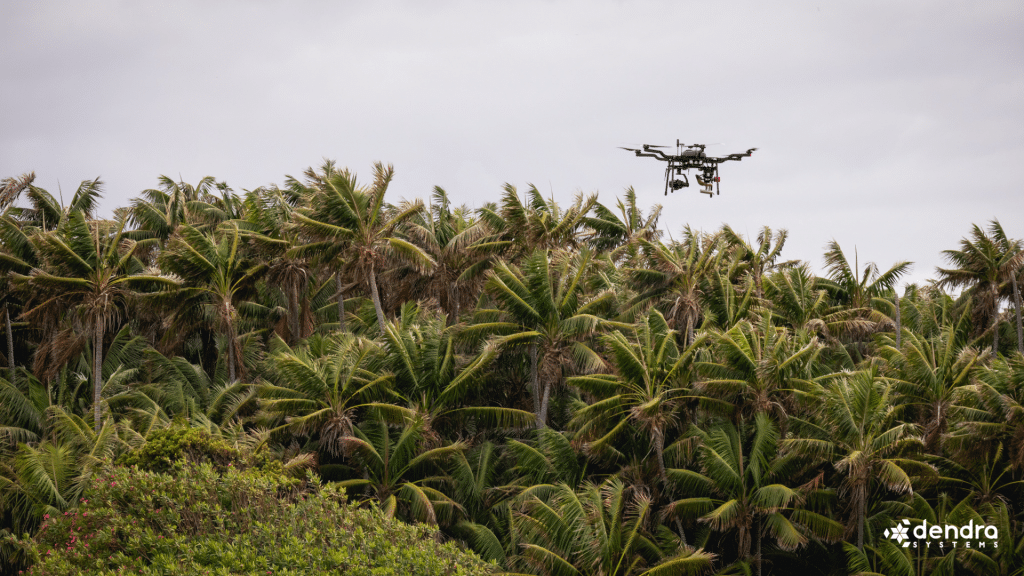

Dendra Systems delivers environmental technologies for ecosystem restoration on a very large scale.

Founded in 2014 with offices in the United Kingdom and Australia, this company approaches habitat restoration in a highly systematic manner, outfitting drones with mapping and seed delivery systems to affect large-scale habitat restoration for a variety of applications.

Dendra Systems products and services break down along two major lines – integrated digital platform and seed spreading solutions.

Hannah Redrup is an R&D Hardware Engineer at Dendra Systems involved in the airborne seed delivery side of the company’s business and understands the value that OpenBOM brings to the company.

“We looked at several BOM products and settled on OpenBOM”, says Hannah.

“OpenBOM had the ECAD and MCAD integrations the team required and solved our primary requirement, a single source of truth for all our design data.”

Dendra’s mapping and seeding systems are a combination of designed electronic, mechanical, and hardware components paired with off-the-shelf pieces to build custom platforms.

“Our technology is an integrated platform that consists of data solutions, mapping, and a suite of management tools to deliver ecosystem insights, weed, and erosion detection, native species identification,and we also offer aerial seeding services -”, says Hannah.

“OpenBOM helps our engineering team design and maintain a cross-functional design and deliver the information needed to my (internal) customer”, Hannah explains.

“Before OpenBOM, we didn’t have any systems integration. After a change, many separate BOMs had to be manually updated in several places, OpenBOM took our systems process to the next level giving us an integrated process from design to manufacturing.”

According to Hannah, “We selected OpenBOM for many reasons, excellent Fusion 360 integration, simple and easy import, and export to leverage our legacy data, and of course, the cost and customization to meet our needs.”

OpenBOM has helped Dendra reduce the time necessary to create and edit BOMs in a number of ways.

“The Fusion 360 automatic part number generation is massive for us. It is so easy to click Get Next Part Number!”

“There is no more managing a magic spreadsheet of part numbers that can become so messy.”

“The fact I can allocate the next available part number to a particular part and no longer rely on the Fusion component naming to identify the exact item is a huge benefit.”

The automatic part numbering feature alone significantly improved the quality of our whole process.

Changes and BOM builds take just a few minutes she says.

“Building and rebuilding a BOM is way easier. I don’t have to go through the spreadsheet and count components – super nice.

OpenBOM just makes ordering parts easier.

Learn more about Dendra Systems – dendra.io

Learn more about OpenBOM – openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.