Product data management is no longer just about locking files in a vault. Modern engineering teams work across disciplines such as mechanical, electrical, software, and across tools (SolidWorks, Onshape, Altium, GitHub, etc).

Internal and external users collaborate globally, make informed decisions faster, and need easy access to accurate, product-related data. Traditional product data management systems, built in a document-centric era, simply can’t keep up.

At OpenBOM, we believe it’s time to reimagine product data management (PDM) for today’s engineering challenges. Our approach is cloud-native, collaborative, and built for the way real teams work across modern and legacy tools alike.

From Vaults to Collaboration: The Shift in Product Data Management (PDM)

Legacy PDM systems emerged from a world of Windows desktops and file servers. Their primary job was to control who could check out a file and prevent accidental overwrites. This worked in single-office, single-CAD-tool environments, but that world is gone.

Today’s engineering reality is very different:

- Teams are distributed across the globe and often work remotely.

- Products are multi-disciplinary by nature and include mechanical enclosures, PCBs, firmware, and embedded systems.

- Essential tools and digital assets vary widely – some teams use cloud CAD (computer aided design) like Onshape, others still rely on file-based tools like SolidWorks or Altium Designer.

Example: A medtech startup might use SolidWorks for mechanical components, Altium 365 for electronics, and GitHub for firmware. These systems don’t talk to each other, and managing the changes between them is a manual, error-prone process.

That’s where the cracks in the traditional PDM system begin to show.

The Real Problem: Disconnected Tools and Fragmented Data

Engineering data is scattered across numerous systems, related to separate

business processes, which include:

- File servers

- CAD data vaults

- Cloud repositories

- Excel sheets

- Shared drives

- Emails

Each system may have its own data governance mechanism – or none at all. And even if individual tools are organized, there’s rarely a single source of truth that brings all the data together.

What’s missing is a unified layer, a centralized platform that connects these systems and ensures everyone is on the same page with access to accurate product data.

Example: When an engineer changes a motor in CAD, but the procurement team is still working off an older BOM in Excel, the change results in misordered parts, production delays, and wasted budget.

Rethinking PDM Software: The OpenBOM Approach

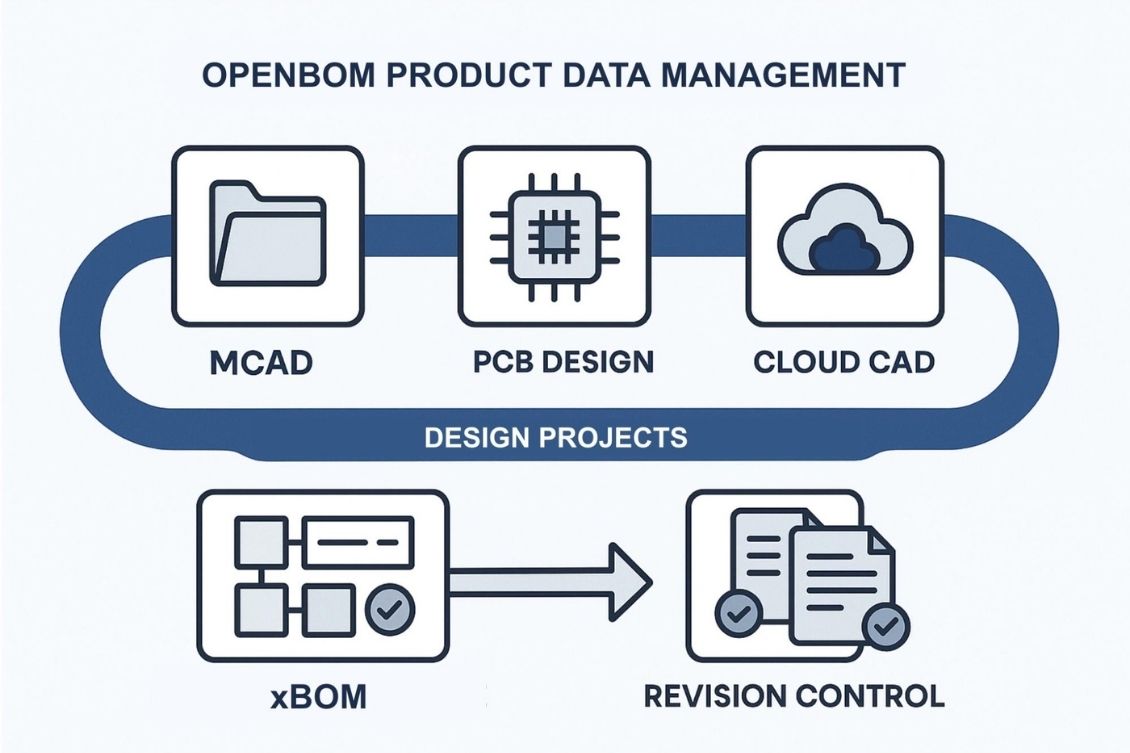

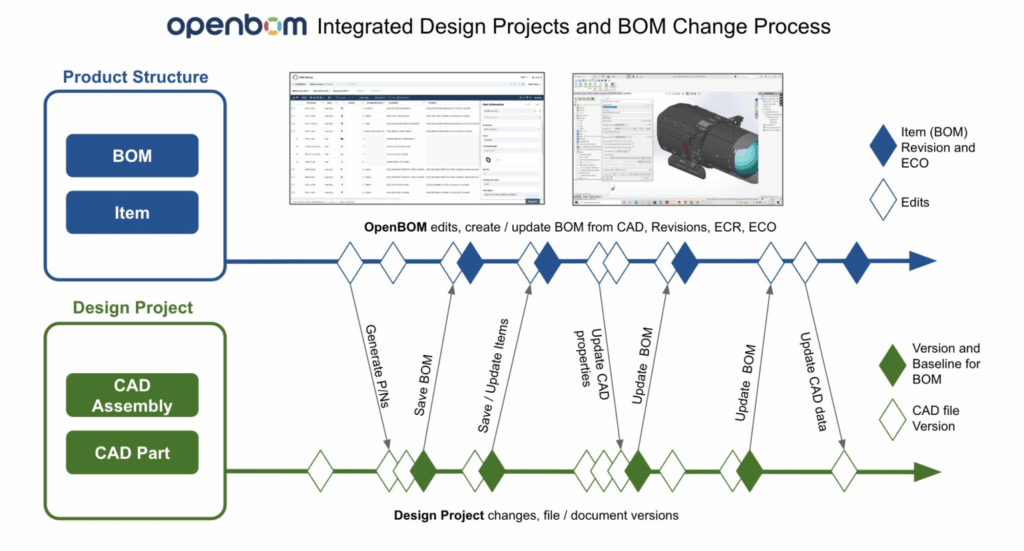

OpenBOM remasters PDM by breaking it down into two levels: (1) design files (or data) and structured product information (xBOM), and connecting them with a unified, cloud-based architecture using a multi-tenant, scalable product data management software.

Design File: First Product Data Management Layer

Most PDM systems only manage product-related data files. OpenBOM product data management software does this too, but in a smarter, more flexible way.

Smart Sync Cloud-Based PDM Data Storage

This feature reduces errors, enhances data accuracy and provides easy access to up-to-date information. Product data files are stored in the cloud, updated automatically, and always accessible without the need for local servers or IT overhead. A mechanical engineer working on a new electric scooter frame uploads the assembly into OpenBOM via the SolidWorks plug-in. It’s stored in the cloud and updated automatically, so a teammate in another office can access it immediately without emailing ZIP files or using Dropbox.

Design Projects

Organize files by product, team, or program and decrease time searching for specific product data. Each project acts like a folder with built-in file management and version control. A team working on a modular IoT sensor creates separate design projects for hardware, electronics, and packaging – each with its own structure but managed in a central repository.

Collaborative Lock and Check-in/Check-out

Prevents file conflicts and improves collaboration while still enabling multiple users to contribute in parallel. One engineer checks out a file to redesign a mounting bracket. At the same time, another updates the documentation and drawings for compliance. No conflicts, no lost work.

Native CAD Integrations

OpenBOM easily integrates directly with SolidWorks, Altium, Fusion 360, and others to capture file data and synchronize metadata. From within Fusion 360, a user can generate a BOM with thumbnails, descriptions, and part numbers, all synced to the OpenBOM workspace, in one click.

Item and xBOM: Second Product Data Management Layer

Beyond files, the real value lies in organizing structured product data – Items, BOMs, suppliers, revisions, and automated workflows.

Item-Driven Product Structure

Each part or subassembly is tracked throughout the product development process as a unique Item with its own metadata, revision, cost, and supplier information. A company sourcing lithium-ion batteries creates a single Item definition that includes vendor information, spec sheets, and pricing. That Item is reused across multiple products and BOMs without duplication.

Multi-Disciplinary BOMs

Bring together components from different domains, including mechanical, electrical, and software, into one cohesive product structure. An autonomous vehicle startup creates a BOM that includes SolidWorks-designed parts, Altium-managed PCBs, and even firmware module names from GitHub. All of these are tracked in a single multi-level BOM in OpenBOM.

GitHub-Style Revision Control

Items and BOMs can be updated, branched, and approved using a clear, traceable mechanism. A change in a PCB layout triggers a new BOM revision. The previous version is preserved, and both can be compared to identify what changed and why.

Collaborative Editing and Approvals

Teams can edit product structures in real-time and submit changes for review and approval without emails or spreadsheet chaos. While an engineer updates part weights and materials, the procurement team adds supplier codes and costs – all in the same BOM. Once ready, the changes are routed for approval and locked in before manufacturing.

OpenBOM Architecture: Flexible, Scalable, Built for the Cloud

At its core, OpenBOM PDM software provides a flexible architecture that supports the needs of modern and legacy environments alike.

- Two-level model – File control + structured product data

- Cloud-native, multi-tenant – No servers to manage, accessible from anywhere

- CAD-integrated – Works with desktop and cloud tools out of the box

- Graph-based model – Supports complex relationships across assemblies, revisions, suppliers, and documentation

This architecture powers OpenBOM’s ability to improve business performance and ensure the efficient operations of small startups as well as large engineering teams managing thousands of items and changes.

Use Cases and Benefits

OpenBOM PDM software helps companies of all sizes bring order, collaboration, and clarity to product data management. Here’s how:

Manage File-Based CAD Projects

Eliminate version confusion and email chaos by securely managing SolidWorks, Altium, or Inventor files in the cloud. A contract manufacturer with multiple clients uses OpenBOM Design Projects to manage separate CAD datasets per customer, ensuring confidentiality and consistency.

Connect Cloud Design Tools

Easy integration with Onshape, Fusion, or Altium 365 to bring cloud-native and desktop workflows together. A product development firm uses Onshape for industrial design and Altium 365 for PCBs. OpenBOM unifies both workflows into a single BOM for sourcing and manufacturing.

Create Unified Product Structures

Build comprehensive, multi-level BOMs that reflect real-world product configurations – spanning mechanical, electrical, and digital domains. A bicycle manufacturer builds a top-level BOM with hundreds of components, including aluminum frames (from SolidWorks), e-bike motors (from a vendor), and embedded sensors – all structured and tracked in the OpenBOM product data management system.

Enable Multi-User Collaboration

Empower teams to work together with the same data in real-time without blocking each other or duplicating work. A design engineer and a procurement specialist work in parallel: one updates specs, the other adds cost rollups. They finalize the BOM together in a shared session, accelerating release.

Track Revisions and Approvals

Gain complete control over what changes, when, and why, improving data quality, avoiding errors, and ensuring compliance. Before sending the final BOM to manufacturing, the product owner reviews the latest changes, compares them with the previous release, and locks in the approved revision for production.

Conclusion: A New Generation of PDM

The OpenBOM PDM system is more than a file management tool. It’s a collaborative, connected, and cloud-native workspace that supports:

- Traditional file-based CAD workflows (SolidWorks, Altium)

- Modern cloud-native design tools (Onshape, Fusion, Altium 365)

- Structured, item-based product data and BOMs

- Real-time collaboration and change management

Whether you’re building robots, medical devices, consumer electronics, or heavy equipment, OpenBOM PDM adapts to your process, connects your tools, and brings clarity to your product data.

Ready to experience a new generation of PDM?

👉 Start your free trial at www.openbom.com or contact us for a live demo.

Best, Oleg

FAQ

What is a Product Data Management (PDM)?

Product data management (PDM) is a unified platform used to manage product data and all product-related processes within one system. A robust PDM system will ensure that all information is accurate and properly managed. A product data management system allows every team member to access and reuse existing design data. The product data stored within the system highly depends on the industry the company is working in. PDM helps to bring complete products to the market faster, improve product quality, and automate engineering processes.

What is the difference between PDM, PLM, and ERP?

Product data management (PDM), product lifecycle management (PLM) , and enterprise resource planning (ERP) are supplementing systems within one company. PDM integrates with CAD software and monitors updates, revisions, and design history automatically. PDM is also a key component of a larger concept: product lifecycle management (PLM), which enables the streamlining of product development and manufacturing processes throughout the entire product lifecycle. ERP is a platform used by the company for the management of key operations that include investment, inventory, purchases, and order tracking.

How different is OpenBOM?

OpenBOM is an online platform that provides a unique combination of PDM, PLM, and ERP capabilities tailored to modern manufacturing and SMB/SME customer size. It integrates with many CAD, ERP, CRM, MES tools and allows companies to start small and grow up with other tools (e.g. more advanced ERP systems) once your business is growing. Check more about OpenBOM Integrations

What Is Digital Asset Management (DAM) Software?

Digital Asset Management software is a unified platform required to keep and organize all digital assets, including videos, images, and 3D models, in one place.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.