A few days ago, I posted an article titled Is your data BOMable?, where I explored the readiness of your CAD data for downstream processes like BOM management, procurement, and manufacturing.

Today, I want to continue this conversation and focus on a critical topic: data quality.

It is hard to underestimate the importance of data quality. In fact, if you still wonder why data quality matters, I highly recommend checking out this excellent conversation between Jos Voskuil and Rob Ferrone – Data Quality and Data Governance – a hype?. They explore and discuss what data quality means in practice and why it is foundational for any digital initiative.

Part Numbers: The Heart of Data Quality

One of the most important (and often most disputed) elements of data quality is Part Numbers.

I’m not going to dive into the endless debate of Smart Part Numbers vs Just Part Numbers here. I just want to state the simple truth:

You need to have them.

Not having Part Numbers leads you to a mess. A big one.

One of my core recommendations to every company starting to use OpenBOM is simple:

“Make an order first. Then bring Software. If you bring computers first, you will create a computerized mess.”

Therefore, regardless of your philosophy about numbering, you need to think about Part Numbers and ensure consistency before importing data from CAD.

Guardrails for Data Import

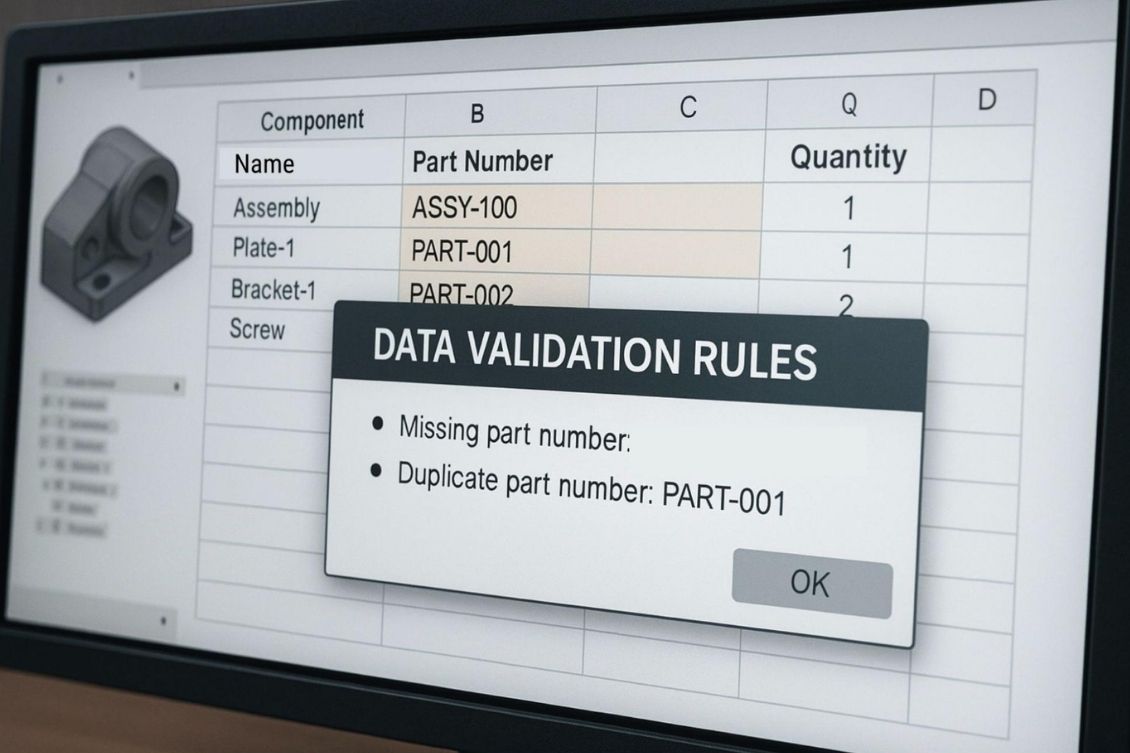

Once you decide on your Part Number strategy, it’s essential to put guardrails in place to protect you from mistakes, duplications, or incomplete data entries.

This is exactly what OpenBOM does with all our CAD add-ins – we check for completeness and duplication of Part Numbers before bringing data into your BOM environment.

Here are a few important notes:

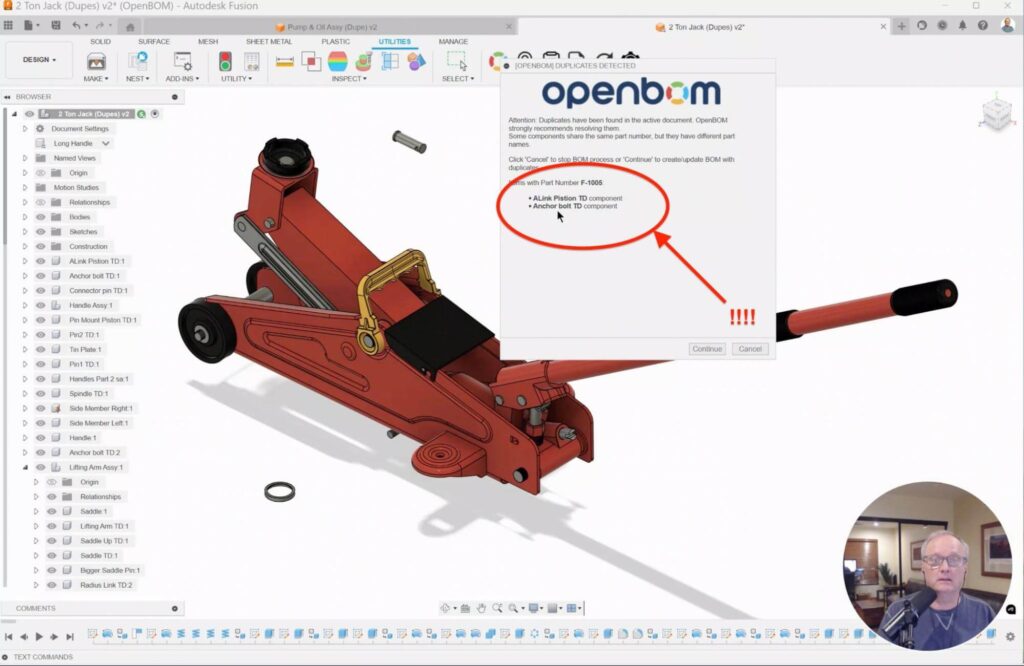

At OpenBOM, flexibility is a core principle.

Some PDM or PLM software will “protect” you by forcing complete renumbering or requiring days or weeks of re-organizing data before import.

OpenBOM is not like that. We help you bring your information into the system in the most convenient and simple way, while still ensuring data integrity.

You can choose to re-use your existing numbers or generate new ones according to your preferred strategy.

However, one important thing is validated in all imports – the uniqueness of Part Numbers.

Example: Part Number Validation in OpenBOM for Autodesk Fusion

Here is a quick video example showing Part Number validation using OpenBOM’s integration with Autodesk Fusion:

We have more ideas about how to improve data quality but would like to encourage you to speak up about what is important to you. Please reach out and talk – about how we can improve data quality when importing data from CAD to create BOM and work on supply chain and procurement.

Conclusion

Data quality is important. It starts from identifying all items – custom components, off-the-shelf parts, assemblies – and ensuring there is a unique and complete set of them in your OpenBOM account.

This simple discipline will save you countless hours of rework, reduce errors in procurement, and build trust in your digital processes.

Want to check how OpenBOM can help you ensure data quality from CAD to BOM to procurement? REGISTER FOR FREE and get an instant 14-day trial.

Best,

Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.