Norway’s Vital Things engineers contactless medical sensors for measuring human vital signs and OpenBOM is at the center of their design process.

The company’s COO, Dag Brænd, leads the product development and is implementing an entirely new digital infrastructure along the way, an incredible task by any measure and one OpenBOM is pleased to be a part of.

“We have developed an entire engineering and manufacturing digital design flow based on OpenBOM”, says Dag.

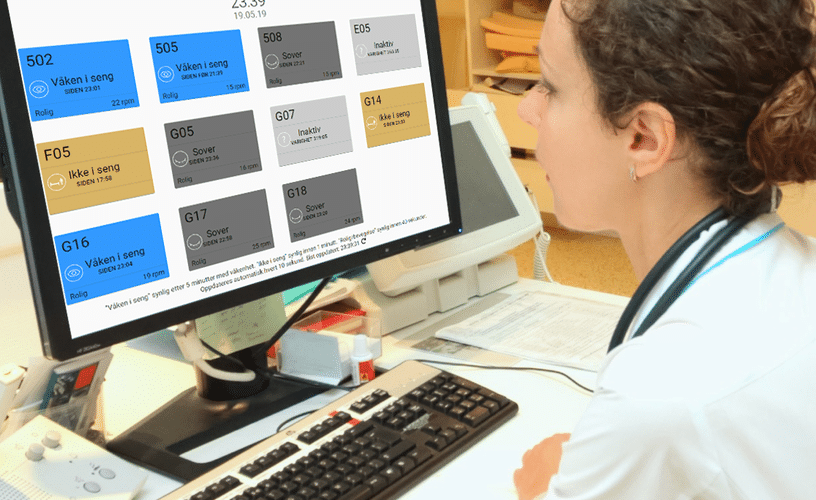

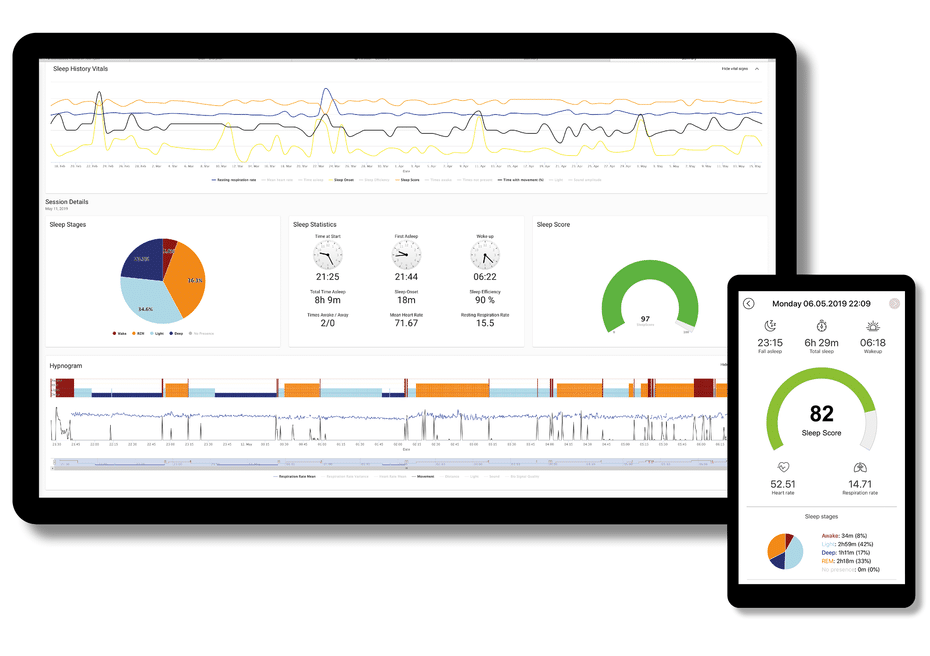

Founded in 2017 by Ole Johan Ellingsen and Alf-Egil Bogen, both formerly engaged with IC industry leader Novelda, the company’s devices track small movements and report them as task-specific medical devices would, but without any contact with the patient.

“OpenBOM is the centerpiece in engineering for all articles of development,” explains Dag. “All mechanical and electrical/PCB components and PCBAs, specifications, certifications, instructions and more are controlled in OpenBOM.”

Vital Things is in a heavily regulated industry governed by medical regulatory agencies worldwide.

“The medical device industry is very regulated so we need reliable and measured operations and manufacturing processes on both the front and backend”, he says, “including the need for a fully controlled bill of materials.”

The bottom line, their designs may not contain any generic components of any kind, everything must be specified and controlled.

Dag and Vital Things had very specific needs when they started looking for a data solution.

“I was looking for a system that could hold complex BOMs and revision, control them in a sensible way. I have a lot of experience with large, expensive, cumbersome ERPs like SAP and others, I knew these big traditional systems were not going to be a fit at my company.”

“We looked at many other systems, while most contained the basic logistical features we needed, none of the alternatives focused on the hierarchical BOM and revision control that was required by our industry.”

“I needed an alternative and OpenBOM fit my needs exactly.”

Vital Things has a complex product structure with many types of components; mechanical, electrical, PCB, certifications, software and firmware, process specifications, and much more.

“My team functions as both internal and external consultants and we needed a common accessible digital location to place all input documents for all systems and OpenBOM meets those needs perfectly.”

“OpenBOM provides the digital infrastructure we need.”

“There are several specific OpenBOM behaviors that you just won’t find in other systems, even the largest ones. The people at OpenBOM really understand how engineers make and consume BOMs.”

“For example, OpenBOM can accurately and immediately flatten a multi-disciplinary multi-level BOM so I can send it to the factory. This alone makes purchasing of a hierarchical BOM very easy. Add links to components and the contract manufacturers love it!”

“Another feature you just won’t find anywhere else is the ZIP export with associated files. We export a specific BOM revision and create the associated zip file of ALL related specs and cad files. This is a real time-saver for us.”

The engineering team Vital Things is building very complex circuit boards and relies heavily on the OpenBOM for Altium integration.

“We bring entire PCBA’s from Altium into OpenBOM with reference designators and library references, neither SAP nor NetSuite was capable of that.”

As so many companies have discovered, sourcing components in the world today is extremely challenging.

Vital Things relies on the Octopart integration of OpenBOM to understand component availability and design their product around what is available NOW.

“I can easily fetch information about an Octopart item and understand the availability, lead times, and trends, which is extremely helpful in today’s IC market.”

OpenBOM provides a variety of workflow options when it comes to part numbering.

“We often use the Altium part number directly and pass it to OpenBOM but we create our own part numbers for PCBs and PCBAs. Similarly, for mechanical, we like to use our own part numbers. OpenBOM supports both workflows simultaneously, and, when used together, our BOMs and components always our preferred part numbers.”

Dag went on to explain how a business process built around OpenBOM has unlocked a number of other benefits to the company.

“We have significantly reduced the number of ECOs as well as the time to process them,” says Dag, “which overall yields better quality in our product.”

I asked Dag what he likes most about OpenBOM, “Once I got over the desire to have a big system like SAP, I settled in and really experienced the power of flexibility built into OpenBOM.”

“I like the ease of catalog and property table definitions and I really like the visual thumbnail – I did not expect that. I like the CAD and Octopart integration and that I can create a hierarchical BOM with as many layers as I want or need. I like where-used and I like the significant control over filtering and generating output and the option to include all related files in a zip – that’s huge!”

At the end of the day, OpenBOM serves as the central design data hub at Vital Things while reducing the handling time of complex BOMs and updates.

“We realized an 80%-90% time saving to incorporate a simple change. Fewer errors and better results overall. The perfect product for a regulated industry”, says Dag.

To learn more about Vital things please visit www.vitalthings.com

To learn more about OpenOBM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.