OKOS Founder, Hari Polu, says it best, “OpenBOM is a simple solution to a complicated problem.” OKOS, founded in 2010, was acquired in Nov 2020 by PVA TePla AG, Germany, and rebranded as PVA TePla OKOS.

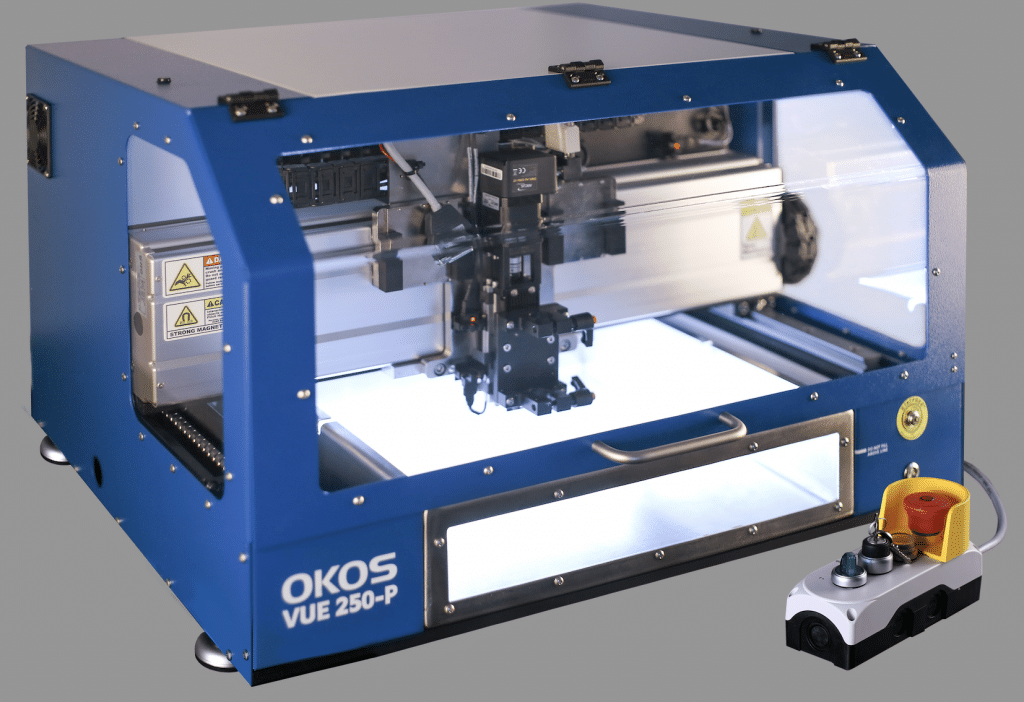

OKOS is a highly vertically integrated manufacturer of Scanning Acoustic Microscopes. Essentially, an industrial sonogram to find defects in anything and everything from electronics to cars, bridges to airplanes.

Hari loves being an early adopter of emerging technologies and has been an OpenBOM customer for many years.

“It works great!”

“OpenBOM gives my team what they need, without the overhead of large, legacy, systems”, he adds. ”Ease of use is what OpenBOM is all about.” We don’t have an IT department; we are just engineers – OpenBOM doesn’t need an IT department.”

OKOS customers are large semiconductor producers and Tier 1 & 2 electronics manufacturers.

“OKOS products offer metrology tools and provide technology/solutions to customers to enhance their processes for reliability and integrity testing,” he says.

“OpenBOM helps us deliver effective metrology tools to our customers.”

“When we started, we ran our builds on Excel”, says Hari, “with all the hardships that come with that, it did not scale.”

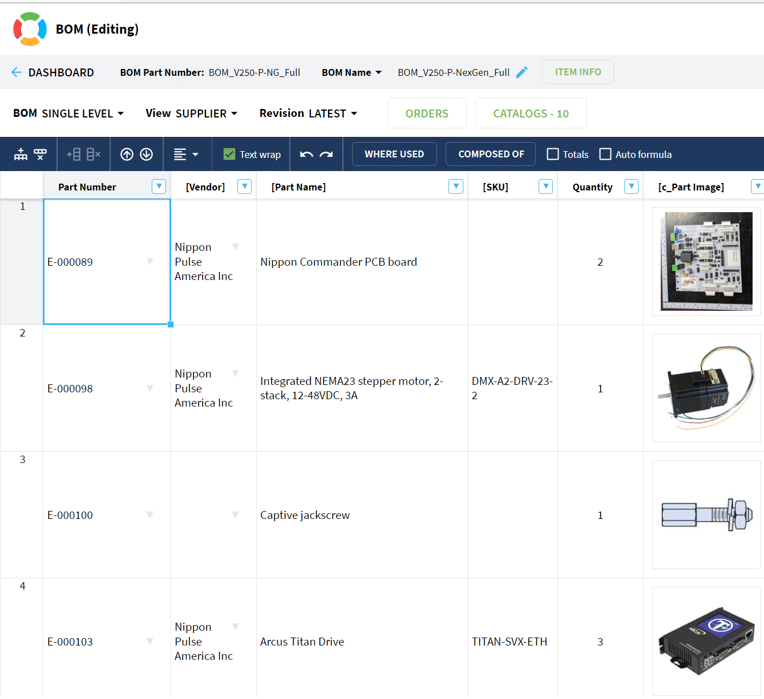

“No images, no versions, no items, we outgrew Excel”; a relentless search found OpenBOM for OKOS; a trial run confirmed what seemed impossible; is there an Excel-like BOM flexible solution for a small manufacturer like OKOS – our search was “Excel AND BOM AND Cloud.”

The initial and running costs of the traditional ERP providers were a non-starter for OKOS, bloated solutions in wannabe cloud wrappers vs. a nimble design for Cloud.

“OpenBOM was an easy, frictionless, implementation for our engineers and assembly technicians. We did not need to read a lot of documentation or hire a consultant. It is a common-sense approach that fits nicely into our business.”

As Hari likes to say, “OpenBOM’s loyalty to images is the secret sauce that makes all the difference.” When we buy items for our products, we print out a view with pictures so we don’t make a mistake. Everywhere people are involved – images prevent mistakes.” The reference data model ensures we have one and only one item that is used in many BOMs.”

“The value of OpenBOM to OKOS is measurable. I estimate the entire team to be 20% more efficient, we reduce our inventory errors and costs and now audit our supplier deliverables.”

But that’s not all…

“The single greatest benefit is a savings of 40 high-value hours every month!”

“What we can do in OpenBOM in 5 minutes will take an hour in a regular ERP.

To learn more about OKOS please visit www.okos.com

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.