Israel based FF Robotics is solving an age-old problem using some very high-tech solutions – How to pick a better apple (actually, any fruit) fresh off the tree!

Using a proprietary gripper, their twelve-arm multi-axis robot gently picks a harvest-ready fruit from its tree and places it perfectly on an automated conveyor which carefully transports it to its final 800lb harvest bin packaging…. All done with the care and precision of a human hand.

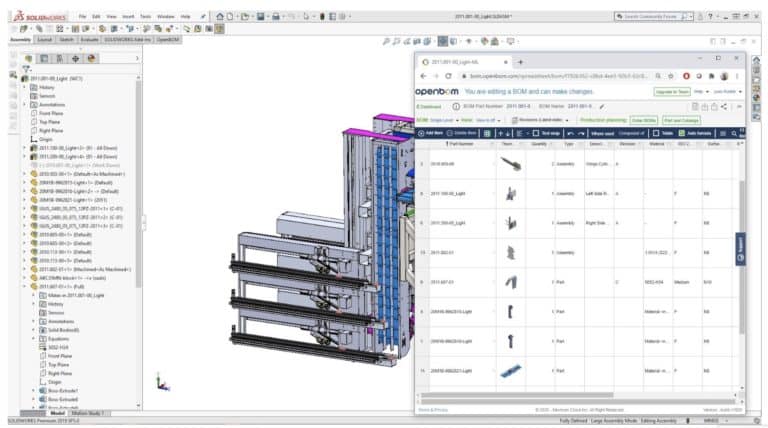

As you can imagine, the machine that mimics the gentleness of a human requires sophistication and precision so FF Robotics selected OpenBOM to speed that innovation to market.

“WIth over 16K individual parts, we needed a better way to manage components,” says FFRobotics co-founder Yoav Koster.

The FFRobotics customers were asking for a solution that lowered the total cost per bin per hour. As growing seasons and labor force availability fluctuates, the challenge is not in the quality of the work – but rather the availability in the region at a specific time. FFRobotics is meeting the needs of its customer with a device with extremely high availability and low standby costs.

“We needed to reduce the number of specific part numbers and OpenBOM makes it easy to understand where each and everyone of the components is being used,” says Yoav.

Something which was not the case when he was using Excel.

“Getting our BOMs out of Solidworks in Excel was hard. We would add some non-modeled items like hardware then have to manage all those additions individually each time we updated the Excel from Solidworks”. Using OpenBOM with SolidWorks and PDMWorks is much much easier, he says.

“OpenBOM easily manages and tracks our part numbers” he goes on to say, “something as simple as finding where a part is used is easy with OpenBOM’s where-used command; not having to open our CAD and look for a part is a huge time-saving.”

Yoav explains in more detail how “Once we had our BOM’s in OpenBOM the real optimization began. We used OpenBOM to identify places where we could standardize. For example, we standardized and significantly reduced our fastener and bearing part numbers. We want fewer part numbers and more standardization. With very little effort we combined standard parts to reduce the BOM significantly. Saving time and money.”

One of his favorite things about OpenBOM is CAD integration. “Every time we extract the BOM from SolidWorks using Excel you have extra work to do to get it right (worse with large assy or subassy). With OpenBOM the update just happens when you click the button.”

“Something we didn’t anticipate was the ease of sharing the BOM with the rest of our team. We have a property for Make or Buy which we set in the Catalog. FF Robotics purchasing department gets the BOM and knows exactly what to do. We could have done it before but it demanded more work and sometimes it just didn’t get done or we made some mistakes.”

FFRobotics Prototype testing in Washington State USA went very well, setting the stage for the production series which is testing now in Israel and Europe (France).

For more information on FF Robotics please visit https://www.FFRoboticsobotics.com/

To learn more about OpenBOM please vitis: www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.