In the world of engineering and manufacturing, one thing is certain—change is constant. Designs evolve, parts are updated, suppliers shift, and requirements grow. To stay in control, organizations must have a structured way to manage these changes across the product lifecycle. This is where revision control becomes essential. At its core, revision control is not just about tracking edits—it’s about creating a reliable system for managing product information as it evolves over time.

Three Elements of Version Control and Revision Management

Document version control and version control features have been well-known for years. This is what PDM software has been doing since CAD software was invented and requires management of document versions to know what is a previous version and how to find version history and the final version of the file. Similar to software source code, version control system focused on how to document versions.

The first foundational element of revision control is the capture of changes. Every modification—whether to a design file, a BOM, or a specification—must be recorded clearly and systematically. This includes what was changed, who made the change when it happened, and why. Without this level of traceability, teams lose context, introduce errors, and risk miscommunication across departments.

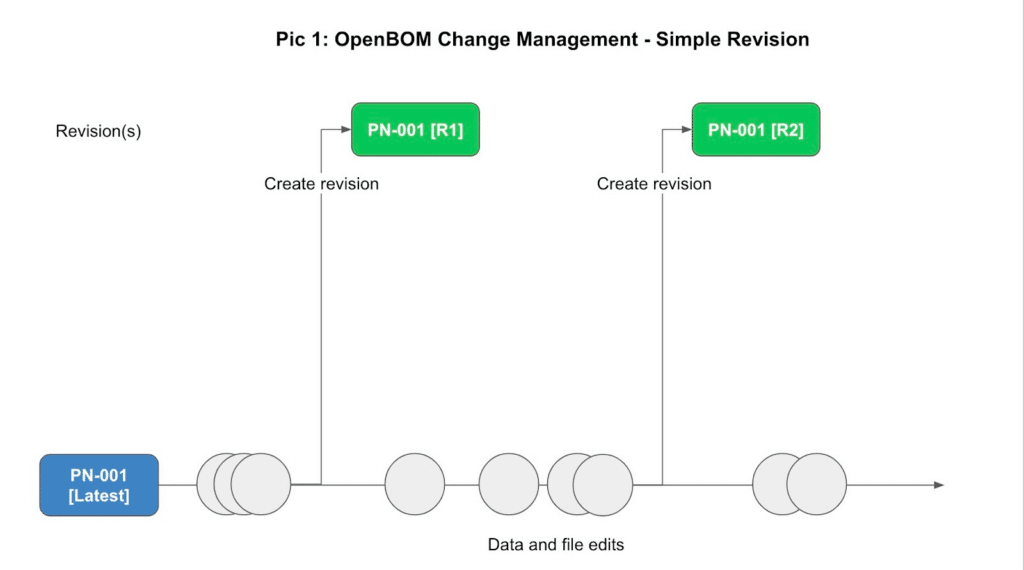

The second key concept is the creation and management of baselines. A baseline is a snapshot of a product at a specific point in time, often referred to as a version or revision. These baselines allow organizations to freeze the state of a product for manufacturing, compliance, or analysis purposes. They serve as reference points to evaluate changes, ensure consistency across teams, and maintain control over what gets built and released.

Finally, interchangeability defines whether a newer version of a component or assembly can replace an older one without disrupting form, fit, or function. This distinction is critical for managing part numbers, revisions, and procurement. Understanding which changes require new part identifiers and which can be implemented seamlessly ensures smooth production and minimizes costly mistakes. Together, these three principles—capturing changes, managing baselines, and defining interchangeability—form the backbone of effective revision control in PLM.

A robust PDM/PLM system should automate version control to allow robust source control of all design information and document control of all product information. While version control is important for design data and is part of version management, overall product revision history is important in a broad scope of all product information (and not only CAD documents).

How Version Control System Works?

Version and Revision Control is a core element of any PDM/PLM System and any revision control software. Therefore, Revision Control is a foundational element of OpenBOM capabilities allowing to capture changes and baselines of product data information from CAD files to Items and BOMs.

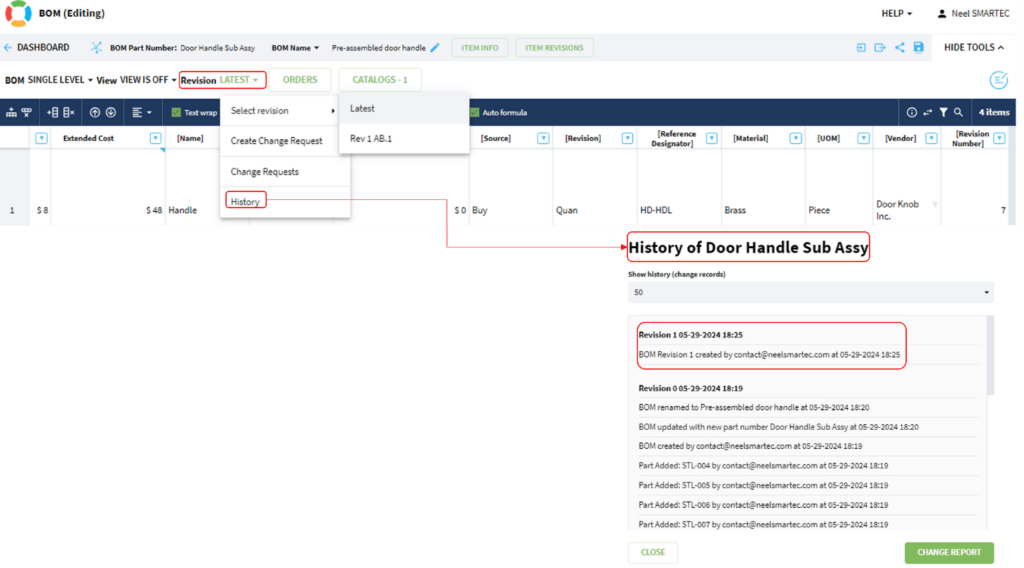

The revision control functions in OpenBOM allow you to capture the entire history of changes in the same document (eg. CAD file), but also the entire history of product information including items, BOMs, linked documents, and other pieces of information. The history allows you always to access prior versions/revisions – this is how version control works. While the versioning system in OpenBOM focuses on design information (CAD files), revision management functions support large projects and span across the entire project team. OpenBOM platform allows you to support collaborative development and it provides a revision management software function to engineering and manufacturing teams.

Managing Change in Engineering and Manufacturing

Change is a fundamental part of engineering and manufacturing, requiring a structured approach to managing product information, including all related data attributes, files, and documentation. Without an effective system, tracking modifications, maintaining consistency, and preventing errors become difficult. Version control and Revision control in a Product Data Management (PDM) or Product Lifecycle Management (PLM) system ensures that product data is systematically updated while preserving historical records. By establishing a robust revision control system, companies can maintain accuracy, ensure compliance with design requirements, and mitigate risks associated with uncontrolled changes.

Managing Complexity Across Multi-Disciplinary Information

Modern products are increasingly complex, integrating multiple engineering disciplines such as mechanical, electrical, and software components. Therefore Version control system is important. Each of these disciplines contributes unique data and dependencies that must be carefully coordinated. A revision control system ensures that changes in one area do not create inconsistencies or failures in another. By synchronizing revisions across interconnected components, teams can maintain data integrity and avoid costly errors in the design, production, or supply chain. Effective revision control supports cross-functional collaboration, ensuring that all stakeholders have access to the latest, verified information.

History, Traceability, and Auditability

At the core of revision control is the ability to manage history through revision baselines and maintain full traceability of modifications. This includes tracking who made changes, what was altered, and when these modifications occurred. Such traceability is essential for accountability, compliance, and quality assurance, particularly in industries that require regulatory oversight. A well-implemented PDM/PLM system ensures that every design iteration is recorded, enabling organizations to roll back to previous revisions if necessary, analyze past decisions, and maintain a clear audit trail for decision-making processes.

Coordinating Teams in the Revision Process

Revision control is not just about tracking data—it is also about managing people and workflows. Different teams and individuals are responsible for specific system elements, and their work must be coordinated effectively. A robust revision control system facilitates collaboration by providing controlled access, structured approval workflows, and notifications for impacted teams. This ensures that all contributors remain aligned, reducing miscommunication and enhancing efficiency in managing product iterations. By integrating teams within the revision process, organizations can accelerate development cycles while maintaining consistency and quality across all product updates.

Why Do You Need Revision Control?

If your product development team is still relying on Excel spreadsheets and shared file folders to manage product data, your company is at risk of costly errors, miscommunication, and inefficiencies. Manually handling revisions in spreadsheets often leads to duplication, version conflicts, and lost data, creating a chaotic and error-prone system. A structured revision control system within a PDM or PLM environment eliminates these risks by providing a systematic way to manage and track changes across structured product information, including files, metadata, and documentation. Those are the ultimate benefits of the version control system including management of version history, allowing access to earlier versions, and centralized revision control systems.

Effective revision control is critical for managing complex product structures, which consist of interconnected systems, subsystems, and components. As products become more sophisticated, their dependencies grow, making it essential to coordinate changes across multiple disciplines. A robust revision management system ensures that updates to one part of the product do not create inconsistencies or incompatibilities elsewhere. By maintaining an accurate, traceable history of changes, organizations can prevent costly rework, improve product quality, and enhance regulatory compliance.

Beyond data and dependencies, revision control plays a crucial role in coordinating people and workflows. Product development involves multiple teams—including engineering, manufacturing, procurement, and service—who must stay aligned when changes occur. Without a controlled process, misalignment can lead to production delays and costly mistakes. A PDM/PLM system provides structured workflows, approval processes, and notifications to ensure that all stakeholders are informed and working with the correct revision of the product data.

Finally, modern businesses need more advanced tools than Excel and file folders to effectively manage revisions. Legacy methods lack automation, security, and collaboration capabilities, making them unsuitable for handling the complexity of modern product development. A proper revision control system provides a centralized, digital framework that enables efficient tracking, traceability, and collaboration across teams. By adopting a structured approach, companies can improve efficiency, reduce errors, and ensure a seamless product lifecycle from design to service.

Why OpenBOM Revision Control is Different?

Changes are inevitable, but with OpenBOM, tracking and managing revisions across items and BOMs is seamless, collaborative, and highly efficient. Unlike traditional PDM and PLM systems that enforce rigid revision processes, OpenBOM offers a flexible, real-time, and user-friendly approach to revision control, allowing teams to work together dynamically without data silos or version conflicts.

Let’s speak about typical version control features and how OpenBOM allows you to manage the revision history of product information.

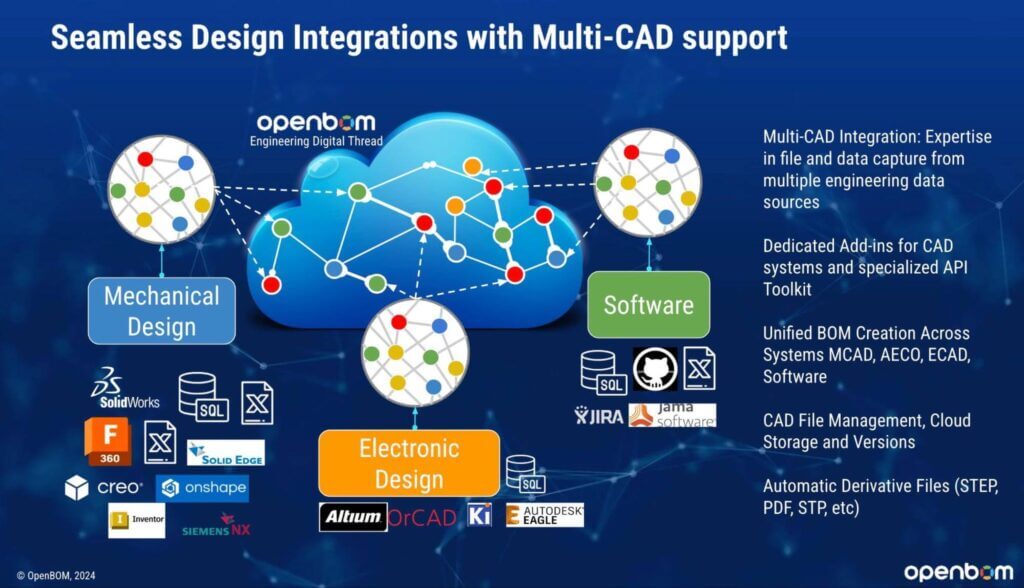

A traditional approach of the last 2-3 decades is to rely on documents and various derivative formats. CAD files come from MCAD, ECAD, and other systems. Derivatives such as STEP, PDF, etc. A single source of truth idea sold as a PDM (and later PLM) solution locked the variety of the information in the database and file vault and controlled who could get access and make a change.

What became typical for those systems is a process “check-out” (literally means take the file), then make a change and “check-in” (return it back). While the process it created was very formal, a growing complexity of product information and complexity of changes (not all changes are the same, not each change requires to increase in the revision, and some changes need to happen in parallel to make the engineering process more efficient).

How to make the work more efficient by ensuring the right data is instantly available to everyone (not via emails with attachments) and how to coordinate change management to include everyone and save time for communication and data updates?

This is where we need to have a paradigm shift to move from central files/folders location to a collaborative workspace paradigm. The need to move from a traditional document management and a PDM system that manages files with check-out/in process to a model with operational efficiency including the following key principles (1) instant data sharing, (2) collaboration in real time; (3) entire lifecycle change process (not silos).

Collaborative Workspace

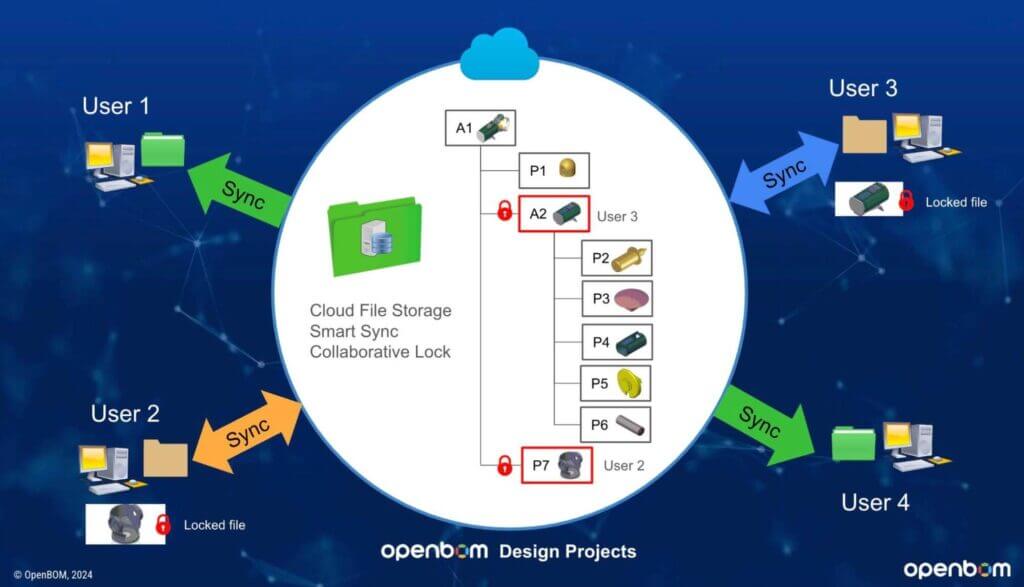

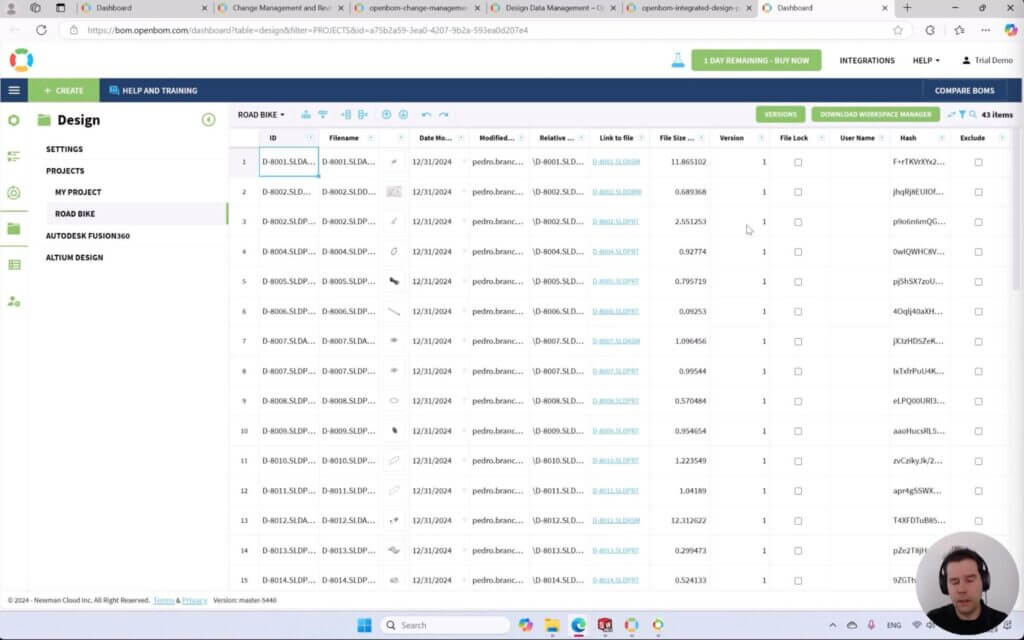

At the core of OpenBOM’s revision control is its Collaborative Workspace, which consolidates all product information in a shared, editable environment. Unlike traditional systems that lock files and restrict simultaneous changes, OpenBOM allows multiple team members to update structured product data concurrently. This system eliminates conflicting changes connects all the files together with metadata and brings multiple projects (mechanical, electronics, software tools) together.

This ensures that the latest design, engineering, and manufacturing information is always available and synchronized across the team. Coupled with real-time collaboration, users can instantly see updates, synchronize with other systems (such as CAD, PDM, and ERP), and maintain a single source of truth across departments.

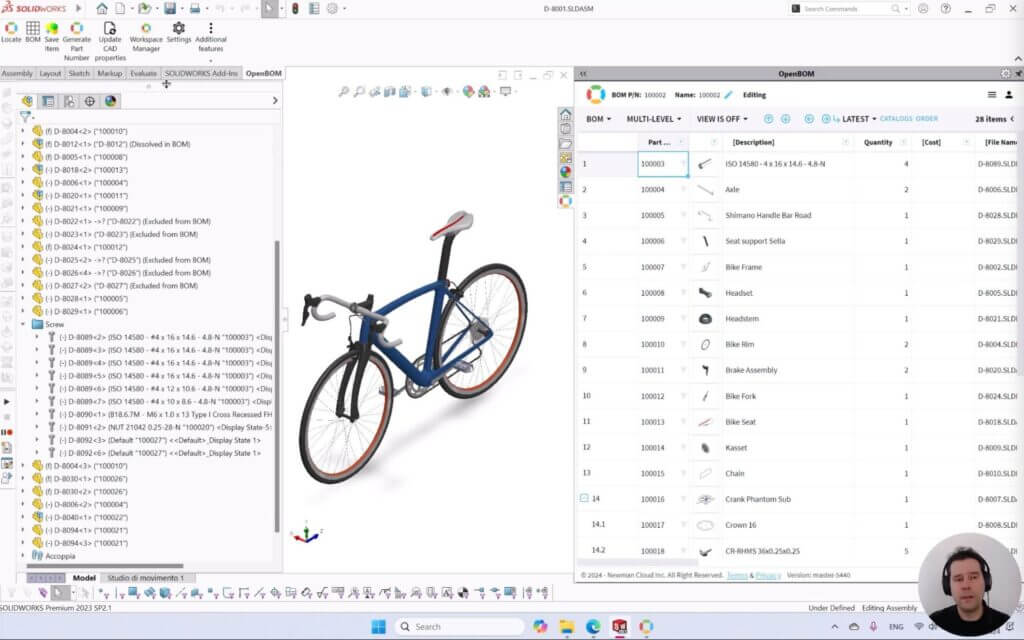

OpenBOM brings a unique mechanism for document version control allowing to manage CAD files and create versions for each design change. This mechanism including Smart Sync combined with collaborative lock allows you to control all file changes for users that not managing CAD files in a separate PDM system or work with cloud CAD with an embedded system. This system is a version control software providing access to previous versions of CAD file versions. A unique smart sync allows concurrent versions system to control changes of CAD files. The same system can be used not only for CAD files, but any document versions and serves as a version control tool for documents, source code, and any files. Altogether it provides a centralized version control system for CAD and other files.

Flexible Data Model and Structured Revision Control Software Functions

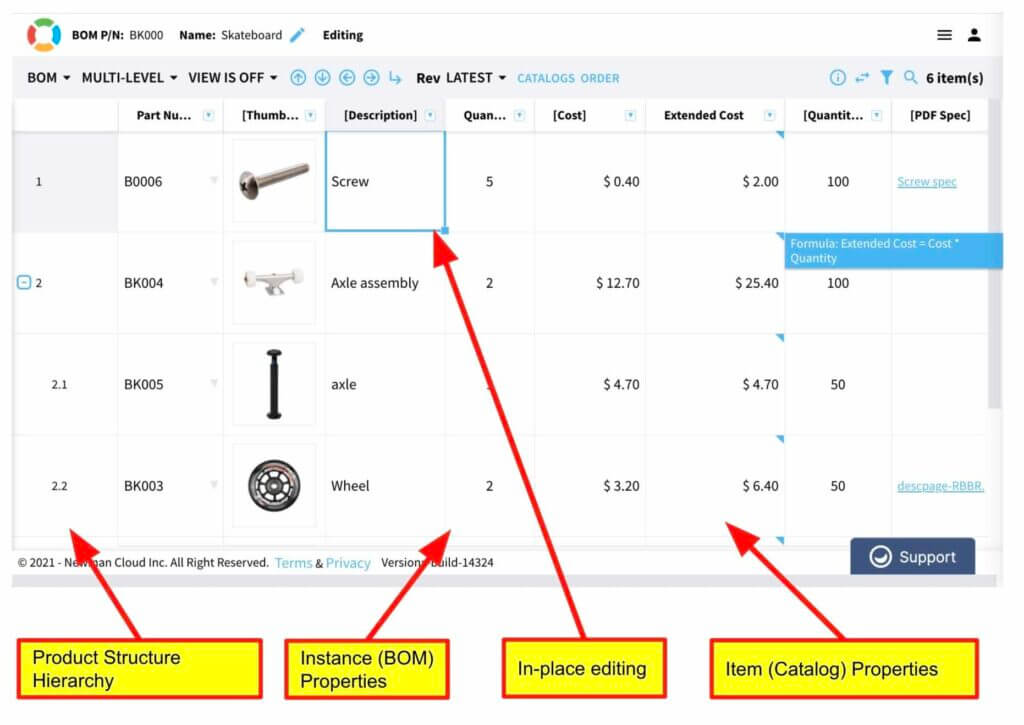

OpenBOM’s flexible data model further enhances revision control by allowing users to customize product structures with additional data attributes and metadata. This adaptability ensures that revision tracking extends beyond just files and BOMs, supporting rich product information tailored to specific business needs. Additionally, OpenBOM’s baseline snapshot system enables teams to create a revision only after multiple contributors have completed their changes, ensuring that revisions capture fully consolidated updates rather than fragmented modifications.

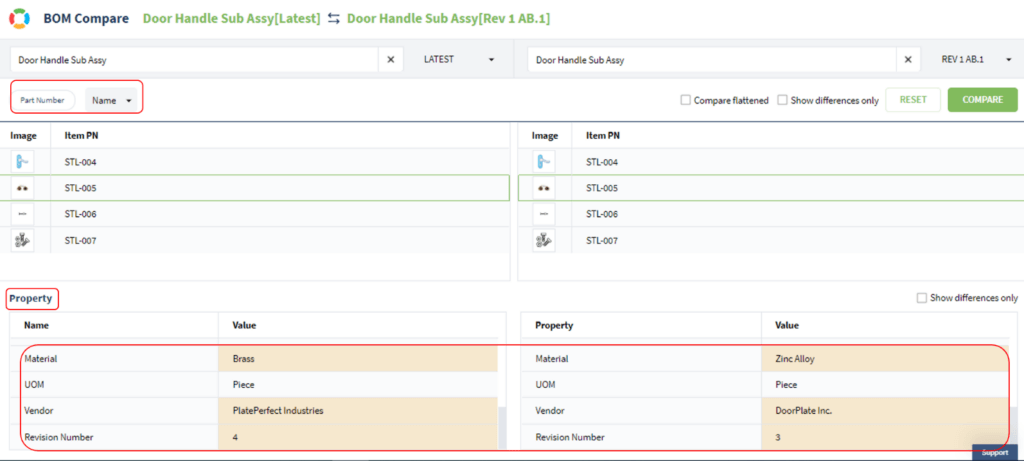

Finally, OpenBOM’s structured item revision management provides complete traceability for both precise and imprecise BOMs, ensuring that Form-Fit-Function (FFF) changes are properly controlled. This level of granularity is critical in managing complex product configurations and regulatory compliance. OpenBOM also offers change tracking and comparison tools, allowing teams to review modifications, generate change reports, and export detailed comparisons. By combining advanced revision control with an intuitive, collaborative interface, OpenBOM redefines how modern product development teams manage change.

How OpenBOM Revision Control works?

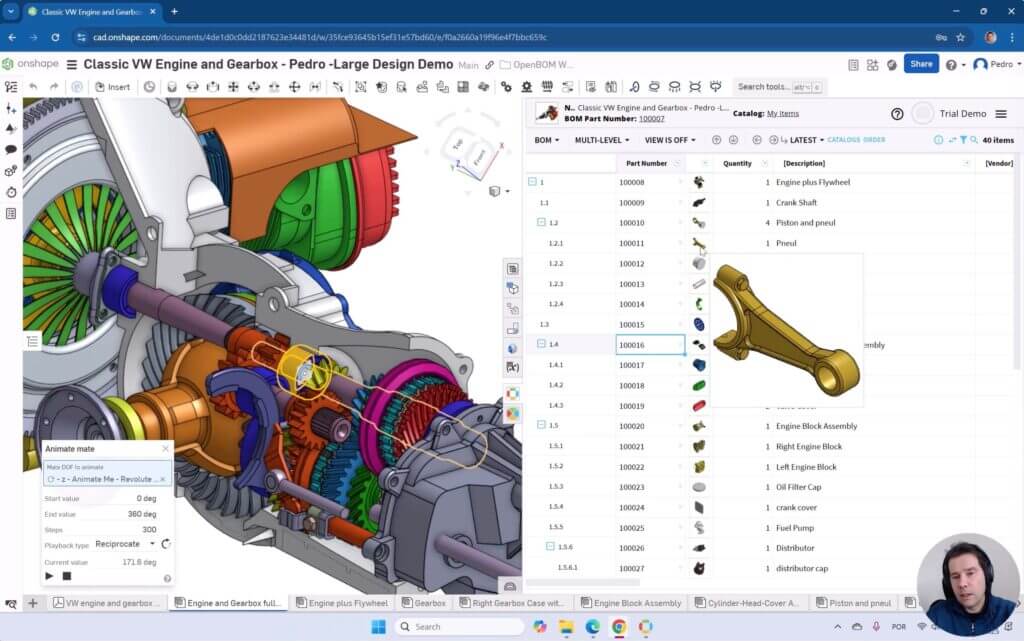

The foundation of OpenBOM’s revision control lies in its structured Design Item, Item, and BOM data model, which serves as the backbone for managing product information. This structured approach allows companies to define, organize, and store all essential product data in a unified framework. Unlike traditional systems that separate BOM structures from item definitions, OpenBOM integrates them into a single, flexible model, enabling efficient revision management across the entire product lifecycle.

At the core of OpenBOM’s revision control are Item and BOM records, which capture all relevant product information, including item properties, BOM structures, and file references. This ensures that every revision includes not only the part list but also critical metadata, design specifications, and associated documentation. Whether managing individual items, subassemblies, or full product structures, OpenBOM ensures that all changes are tracked systematically, eliminating inconsistencies and maintaining data integrity across revisions.

For engineering teams managing work-in-progress (WIP) data, OpenBOM’s Design Items functionality provides an efficient way to control CAD files and other design-related documents before finalizing revisions. This enables engineers to iterate on designs collaboratively while maintaining version control at the file level. Design Items allow seamless integration between early-stage development and formalized revisions, reducing errors and ensuring that only finalized changes are committed to the product structure.

Additionally, OpenBOM’s PDM integration offers optional connectivity to cloud-based CAD systems, ensuring that design data can be easily imported, linked, and versioned alongside product structures. Whether using Autodesk Fusion 360, Onshape, or other cloud CAD tools, OpenBOM provides a direct link between design iterations and structured BOM data, bridging the gap between engineering and downstream manufacturing processes.

This level of integration simplifies change tracking and ensures that design revisions flow smoothly into procurement and production.

Finally, OpenBOM’s revision baselines enable users to capture changes from the collaborative workspace—including items, BOMs, and files—and store them as immutable snapshots. These baselines serve as a historical reference, ensuring full traceability of revisions and providing a secure foundation for audits, compliance, and change impact analysis. OpenBOM supports both bottom-up and top-down revision control, allowing users to manage updates at the component level or across entire assemblies, depending on their workflow needs. By offering structured, real-time, and integrated revision control, OpenBOM ensures that teams can confidently manage product evolution while maintaining data accuracy and collaboration.

Revision Control Best Practices

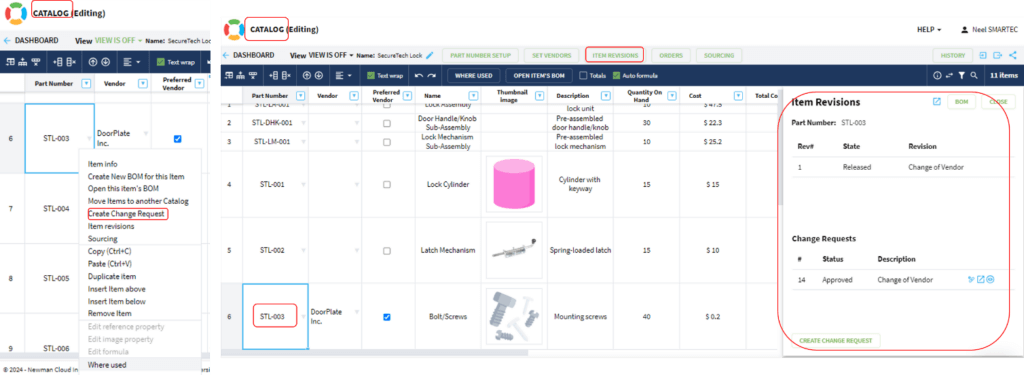

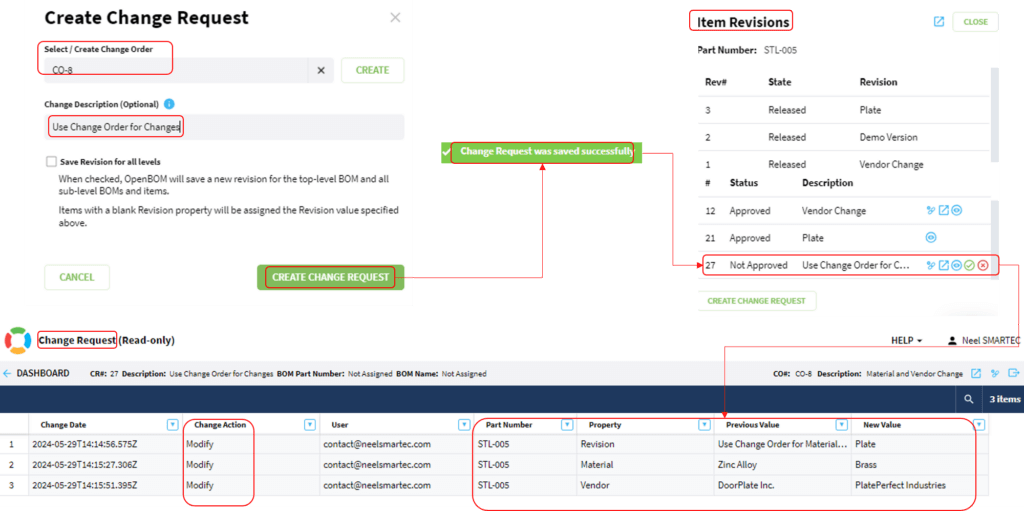

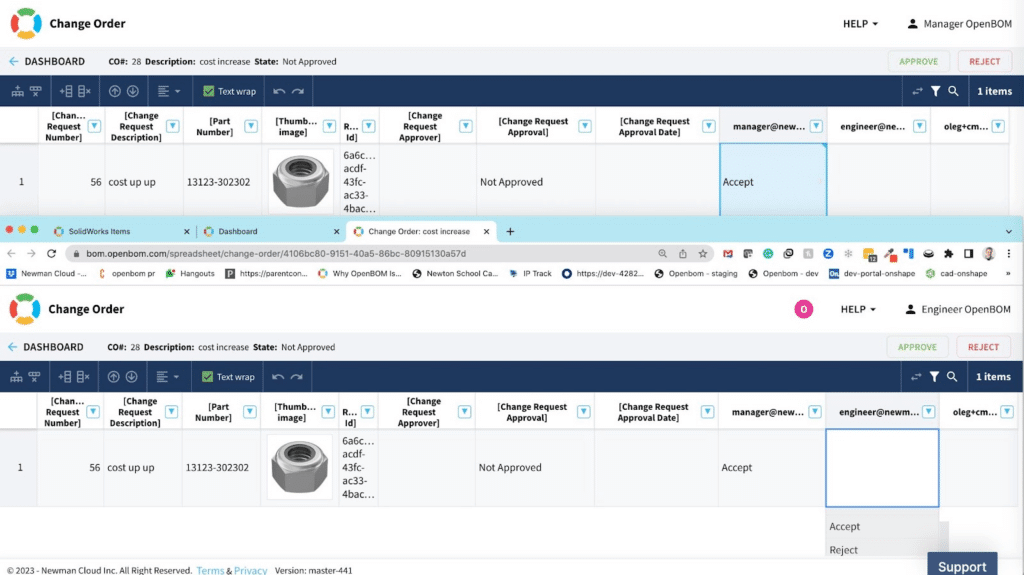

Effective revision control ensures that engineering and manufacturing teams manage product changes systematically, minimizing errors and maintaining data integrity. In OpenBOM, the revision control process is integral to managing Change Requests (CR) and Change Orders (CO). A well-defined change management workflow helps teams track modifications, review proposed updates, and ensure approvals align with project requirements. Using structured revisioning practices prevents unauthorized changes and provides a clear audit trail of all modifications.

The revision control mechanism in OpenBOM consists of Change Requests and Change Orders, each serving distinct purposes. A Change Request (CR) documents proposed modifications such as part updates, vendor changes, or material substitutions. Once reviewed and approved, the Change Request is linked to an updated item revision.

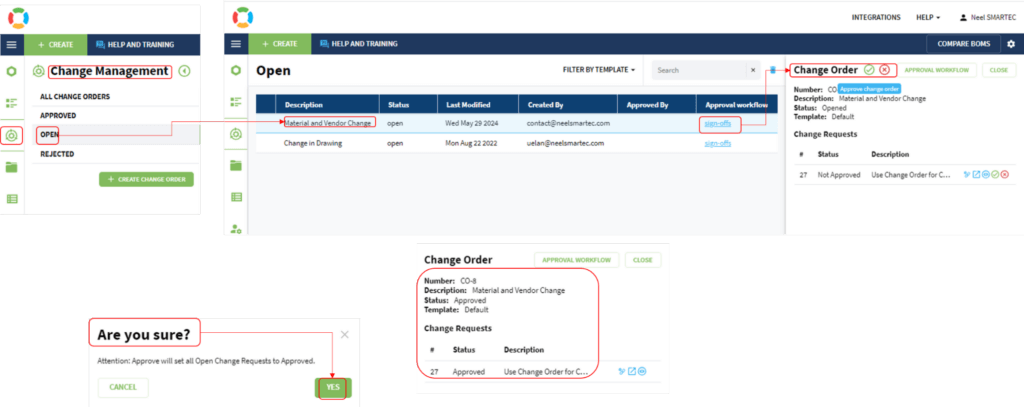

Change Orders (CO), on the other hand, consolidate multiple Change Requests into a single workflow, streamlining approvals and ensuring synchronized implementation of related changes.

This structured approach enhances traceability and simplifies change tracking across the product lifecycle.

Best practices in revision control emphasize clear documentation, thorough verification, and effective communication. Change descriptions should be specific and concise, helping reviewers understand the proposed modifications. Regularly verifying changes before submission reduces errors and ensures data accuracy. OpenBOM’s BOM Comparison tool aids in identifying differences between revisions, allowing teams to validate updates efficiently. Additionally, maintaining proper documentation of all revisions and approvals enhances compliance and facilitates seamless audits.

Collaboration is a key aspect of successful revision control. Stakeholders should be actively involved in the approval process, using OpenBOM’s collaborative workflow to provide feedback and ensure alignment.

Early communication with relevant teams prevents delays and improves decision-making. By grouping similar changes into a single Change Order and tracking approval statuses, teams can streamline the revision process, reduce disruptions, and maintain an organized, controlled approach to product updates.

Versions and Revisions Terminology

The question related to the naming of revision history and version control system can be confusing sometimes. Very often customers speak about accessing the latest versions of the same file, asking about revision control for documents and data, asking about distributed version control system meaning access changes in multiple systems, questions about the current version, central repository of all data, complete history, different versions and many others.

At OpenBOM, we stick with a specific naming convention:

- Version applies to the changes of CAD files and other documents managed in design projects

- Revision applies to the changes of Items (in catalogs) and formal change control system.

Engineers usually start with design, managing it using Design Project versions (or integrated CAD/PDM systems), and the data retrieved in OpenBOM Catalogs for future revision history.

Check the following articles for more information about revision control using OpenBOM.

How OpenBOM Transforms Engineering Data and Change Management Using Collaborative Workspace

OpenBOM How-To Series: Change Management End-to-End Process

From CAD Design to Product Release: Enhancing Collaboration with Integrated CAD and Digital BOM

OpenBOM Day in Life Video: Streamlining Product Development with Digital Data