Any construction site foreman or framing contractor will tell you the one most time-consuming activities on the job site is chalking out the floor layout. It’s error-prone and takes tedious measuring and marking.

Enter Canada’s Mechasys with a brilliant solution – the FramR system. No tapes or chalk.

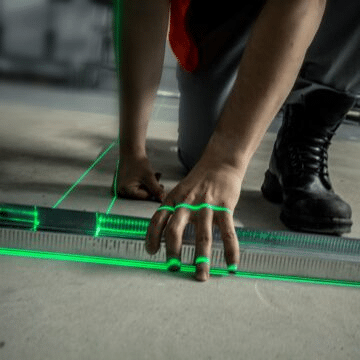

The laser-based device accurately projects the plan layout of walls, pipes, HVAC, and other features identified in a construction plan in green laser onto the floor or ceiling.

FramR tells folks on the job site where to put material!

Founded in March of 2018, Mechasys is building FramR with OpenBOM.

Anne-Lyse Miller is the company’s Supply Chain Manager and leads the OpenBOM implementation at Mechasys.

“We started with Excel which met our needs for a while, but later as we matured and moved towards manufacturing, it became very messy”, she explains.

“Our product is compact and contains a variety of engineering and component disciplines. We have optical, mechanical, electrical, off-the-shelf components designed for manufacture both in-house and by outside suppliers,” she says.

Mechasys also needed to track lead times and an AVL for a wide range of components.

“FramR has a lot of component information we need to manage, we needed a real manufacturing bill of materials and purchasing solution”, says Anne-Lyse.

“My team took the time and looked at a lot of alternatives before selecting OpenBOM”, she explains, “from the super inexpensive to the extremely complex, OpenBOM was the right choice for us.”

“OpenBOM manages our data smartly, with categories and catalogs that align with the way we design and manufacturer our product.”

“OpenBOM is literally our Single Source of Truth!”

“FramR has a lot of sub-assemblies and OpenBOM manages and updates them accurately. The OpenBOM catalog item definition is the key to accurate item and BOM management at Mechasys, we can’t do that with Excel.”

Leaving Excel behind has had other benefits at Mechasys.

“The company is transitioning from R&D to NPI. We need an accurate, structured BOM to communicate with our supply line and the manufacturing team.”

“OpenBOM gives us just that. We share with internal and external stakeholders, easily exchange BOM data with suppliers, and can deal with a specific sub-assembly easily because OpenBOM naturally divides the BOM into multiple nested levels.”

“Think about a particular PCB or other component or sub-system. Some we buy, others we build in Montreal, some we sub out, over 70% are custom.”

“While in R&D many were 3D printed, but now as we move to HVM we will be transitioning to molding and other methods. OpenBOM helps us manage the transition to those manufacturing methods and suppliers.”

“We love OpenBOM for our engineers. Our Engineers import CAD data using the OpenBOM addin and the rest of the team consumes it in the planning process – it’s that simple.”

“Reflecting back on our implementation with OpenBOM I can say the results have validated our choice to buy OpenBOM.”

“We reduced the number of ECOs BY 35%”

“I must say something about the post-sales experience and onboarding. The OpenBOM team helped us structure and organize our data using much more modern methods. Specifically, we changed our outdated naming and part number practices to a simpler and more reliable scheme – as a direct result of the OpenBOM onboarding process.”

“It is easy to contact and talk to someone at OpenBOM with knowledge of our process and needs. In fact, I built my process around OpenBOM capabilities.”

According to Anne-Lyse, there is a common Q&A within the company.

“Question: How do I get the most updated info about a chip or component, Answer: go to OpenBOM.”

We love that!

To learn more about FramR and Mechasys, please visit www.mechasys.ca

To learn more about OpenBOM please visit www.openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.