The last few months at OpenBOM have been a busy and exciting time. We’ve been on a ride to expand the number of out of the box integrations we offer, helping our customers connect OpenBOM to more of the systems they rely on every day.

From ERP and Financial Systems…

Our initial focus was on adding packaged ERP and financial integrations—areas where the value of connecting product data is immediately clear. Over the past few months, we’ve introduced and improved integrations with:

- QuickBooks (enhanced integrations)

- NetSuite (with more features)

- Odoo (new integration)

- And Xero is coming soon (stay tuned)

- Microsoft Dynamics 365 (soon)

These integrations allow our customers to seamlessly connect engineering and manufacturing data to purchasing, inventory, and financial processes.

Why Integrations Are So Important

Manufacturing companies use different systems, especially when those companies are in different sizes – OEM, suppliers, contractors. Product data lives in CAD, PDM, PLM, ERP, supply chain tools, and financial systems, often scattered across multiple companies and locations. Without integrations, teams are stuck with manual data entry, spreadsheets, and email attachments, which:

- Introduce errors and inconsistencies

- Slow down decision-making

- Break the connection between engineering changes and downstream processes

- Make it nearly impossible to have a single source of truth

Integrations solve this by creating a connected flow of information- from the first CAD design through procurement, manufacturing, and delivery. This ensures that everyone, across all systems, is looking at the same accurate data.

At OpenBOM, we believe this connectivity is essential for building a digital thread – the backbone for modern manufacturing collaboration.

And…To PLM Integrations

Now, we’re turning our attention to PLM integrations, and for our first step, we’ve chosen a platform we have a lot in common with: Aras Innovator.

Why Aras? We both share a commitment to openness. Both platforms believe in giving companies the flexibility to choose the tools that fit their needs and the ability to connect them without proprietary barriers. And both believe in the importance of digital thread.

The Sneak Peek

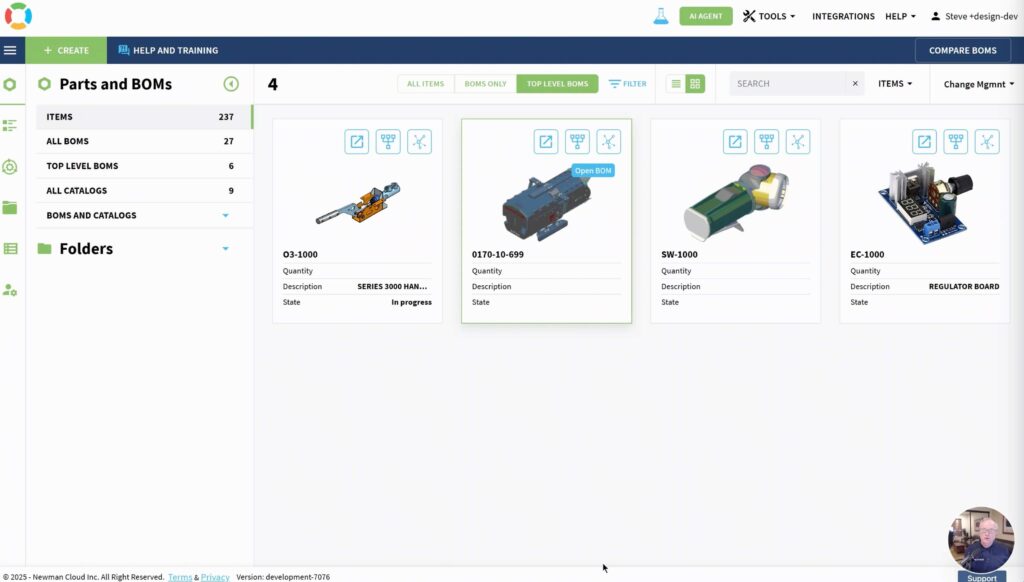

In today’s video, Steve Hess is showing a first look at the OpenBOM–Aras Innovator integration.

Here’s the scenario:

A design contractor is working in SOLIDWORKS and needs to pass accurate product data to an upper-tier OEM, Tier 1 supplier, or partner—someone using Aras Innovator. With the new integration, this process is streamlined, accurate, and built on open data exchange.

The steps are…

1. Get to OpenBOM

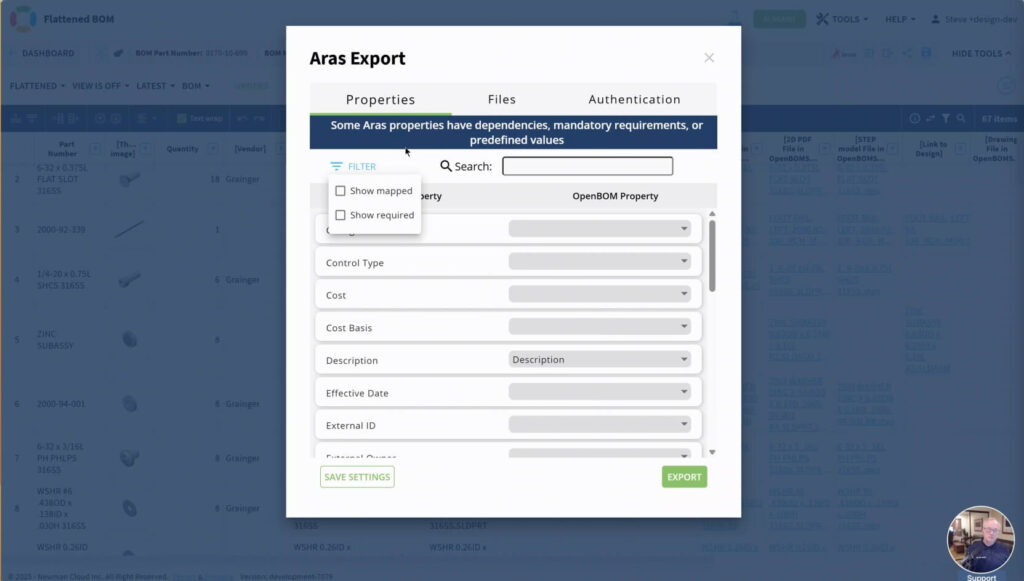

2. Configure OpenBOM to Aras Innovator mapping

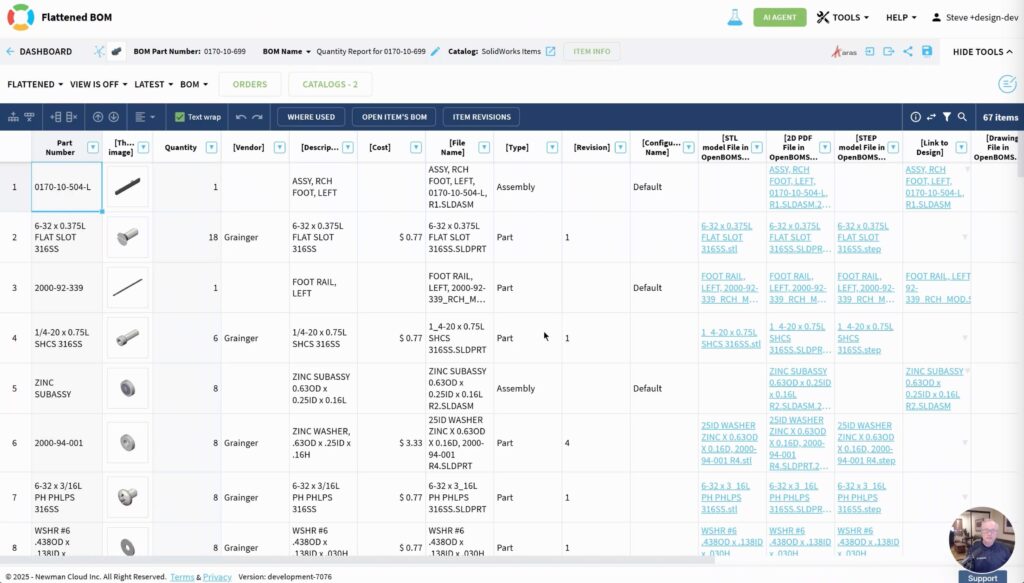

3. Explore the BOM you want to transfer (saved from Solidworks before)

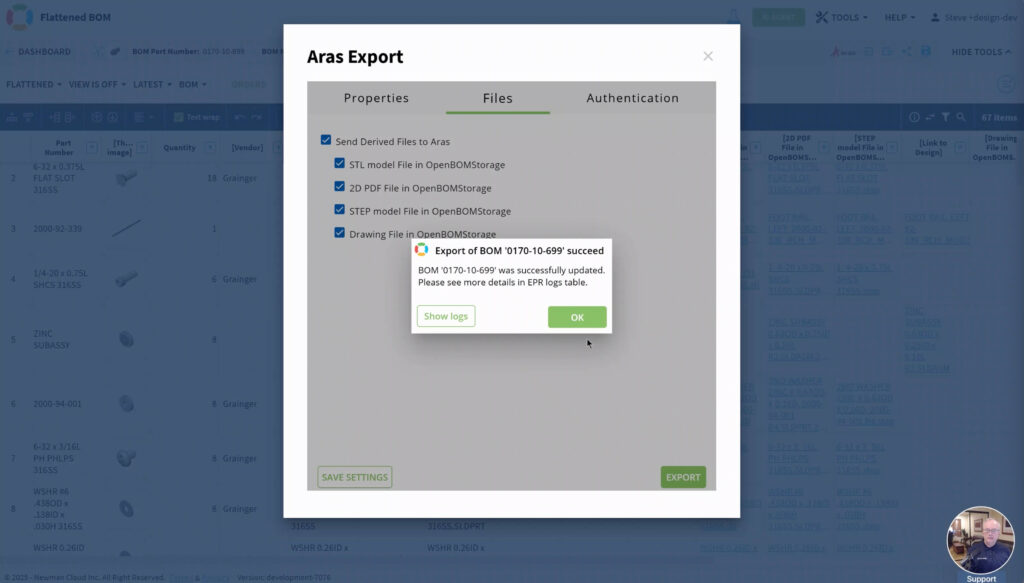

4. Check the mapping and send the BOM with all files

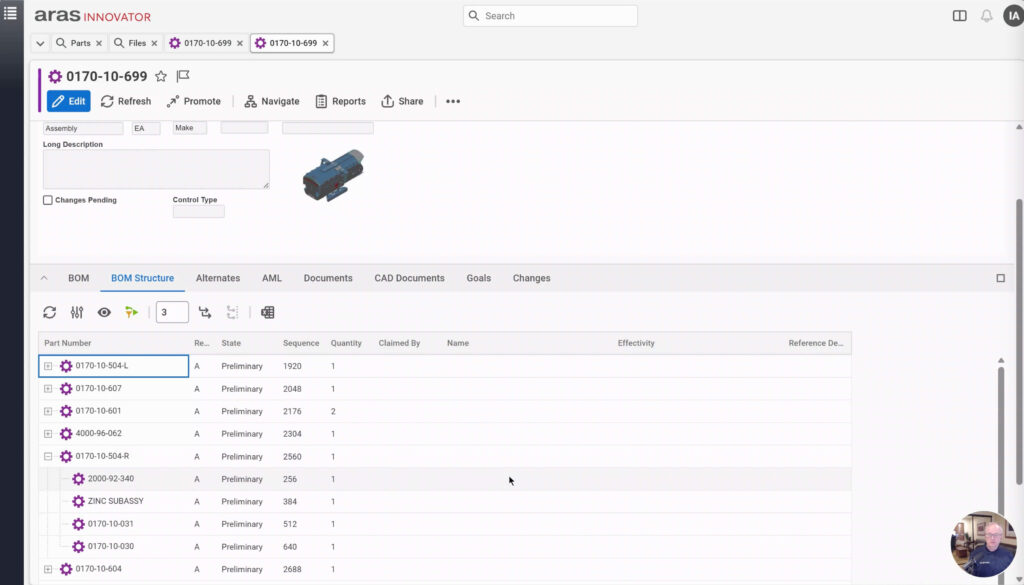

5. Check the Aras

🎥 Watch the sneak peek video here.

Conclusion

Manufacturing today is complex, with product development spanning multiple companies, locations, and systems. Openness and connectivity are no longer optional – they’re essential.

Both Aras and OpenBOM are open and provide an access to APis allow multiple companies and systems to work together, supporting the creation of a connected digital thread across the supply chain.

But we took an extra step and introduced packaged out of the box integration that can be easy configured.

By integrating systems like Aras Innovator and OpenBOM, companies can:

- Reduce manual re-entry of data and the errors it causes

- Keep design, manufacturing, and supply chain teams in sync

- Accelerate time-to-market by removing communication bottlenecks

- Build resilience by making data available across multiple partners and platforms

Stay tuned for more details, demos, and technical information about the upcoming OpenBOM–Aras Innovator integration.

In the meantime, REGISTER FOR FREE to check OpenBOM during the trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.