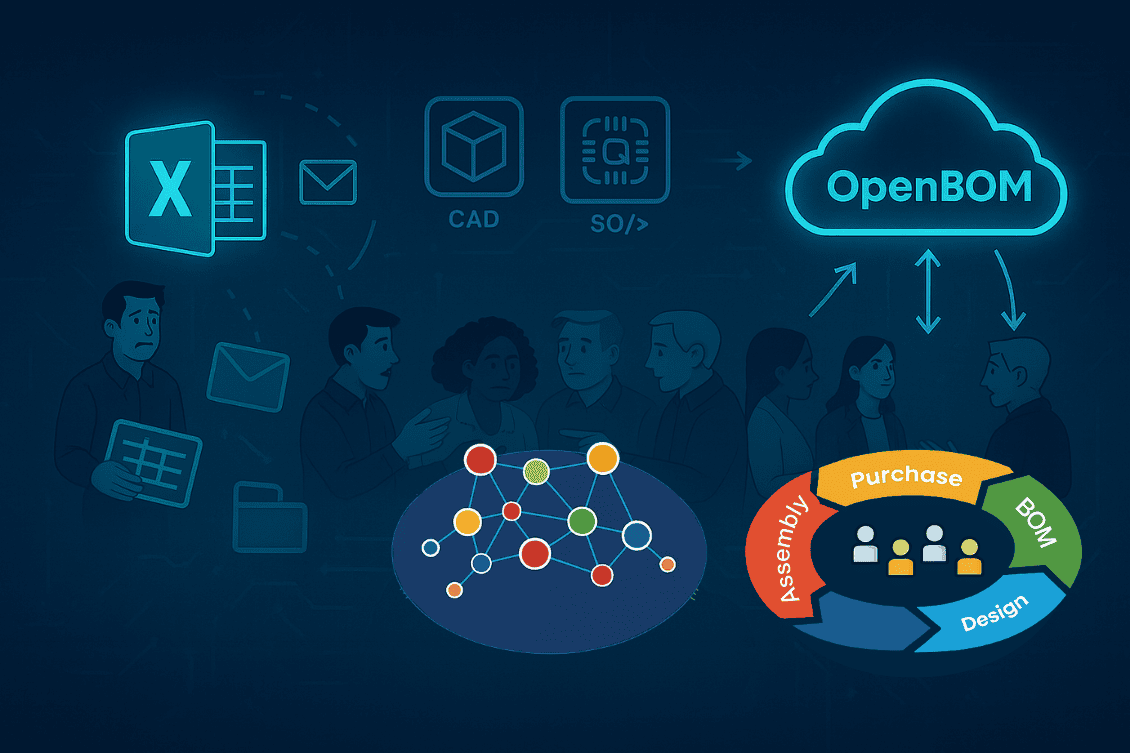

Every engineering team eventually runs into the same question: When do spreadsheets, shared drives, and disconnected PDM tools stop being enough? First, Excel and email can get the job done. But as products get more complex, teams grow, and supply chains expand, those tools quickly turn into bottlenecks.

This article explores the journey from a small team managing CAD files and BOMs with ad-hoc methods, to scaling organizations struggling with silos, and finally to companies ready to embrace a true digital backbone. Along the way, we’ll highlight the pain points that signal it’s time to move to OpenBOM, and how a cloud-native platform can transform the way engineering, procurement, and manufacturing work together.

Early Stage – Startup / Small Team

In the beginning, managing product data feels simple. A startup with one or two engineers can often get by with:

- CAD files saved on local desktops.

- BOMs tracked in Excel.

- Sharing information through email or basic cloud folders.

This setup works when products are relatively simple—dozens of parts, a single CAD tool, and everyone sitting in the same room. But the cracks appear quickly:

- Duplicated files as engineers pass versions back and forth.

- Lost revisions when Excel sheets are overwritten or emailed around.

- Inefficient collaboration when suppliers or contractors need updates.

At this point, issues may seem manageable, but they are the early warning signs that your current process won’t scale.

Growing Stage – Scaling Engineering and Manufacturing

Growth brings both opportunity and complexity. Suddenly, your product isn’t just mechanical: it includes electronics, firmware, and software that must all align. You’re onboarding more CAD users, running multiple projects in parallel, and interacting with a growing supplier base.

This is where traditional methods start to fail:

- Fragmented BOMs. Different spreadsheets exported from MCAD, ECAD, and ALM tools create disconnected versions of truth. The mechanical BOM doesn’t match the PCB design. Item data lives in too many places at once.

- Tool silos. Some CAD systems include their own PDM, but that only adds another isolated repository. Meanwhile, ERP systems demand clean, up-to-date data for planning and procurement.

- Process breakdown. Version control becomes chaotic. Engineering change orders slip through the cracks. Communication with suppliers gets slower and error-prone.

- Cross-functional friction. Engineering, operations, and procurement struggle to stay aligned. Instead of accelerating product development, teams spend time chasing data and reconciling spreadsheets.

Mature Stage – Digital Thread & Beyond

For larger companies, the challenges compound. Engineering, procurement, and manufacturing often operate in silos, with their own systems and priorities. While each function is efficient internally, the lack of connection creates serious problems:

- Procurement can’t trust engineering’s latest BOM.

- Manufacturing works from outdated revisions.

- Engineering doesn’t see supplier constraints until it’s too late.

The missing piece is integration. Organizations need a digital flow that connects CAD, BOMs, ERP, and supply chain data into a continuous, reliable thread. This includes:

- Automatic ERP synchronization.

- Seamless CAD integrations.

- Accurate MBOM creation.

- Procurement and purchasing automation.

At this stage, companies recognize that sending files from system to system no longer works. What’s needed is a cloud-native, connected platform that unifies product data and enables collaboration across the enterprise.

OpenBOM delivers exactly that—serving as the digital backbone that supports complex products, aligns engineering and operations, and prepares organizations for AI-powered insights and automation.

Customer Stories – Recognizing the Right Time

Xponent Power

Xponent Power designs solar-powered awning systems for the RV market, combining mechanics, electronics, and embedded software. Early on, they used Excel and shared drives to manage CAD files and parts lists. That approach broke down as the product matured: design iterations, supplier communication, and cross-domain alignment became error-prone and slow.

When the team adopted OpenBOM, they consolidated their product data into a single environment, improved version control, and enabled smoother collaboration with suppliers. The transformation helped reduce confusion, accelerate iterations, and scale their engineering processes more reliably.

TTM Technologies – Advanced Manufacturing Group (AMG)

TTM Technologies (TTMI) is a global manufacturer of technology systems, PCBs, and engineered solutions. Their internal Advanced Manufacturing Group (AMG) supports in-house manufacturing, tooling, and software systems. As TTM scaled, the AMG team ran into the typical pains of growth: BOMs in Excel, fragmented data, and manually reconciling design inputs with manufacturing needs.

Owen Long, Lead of AMG at TTM, explains:

“We had old BOMs, new BOMs, BOMs in Excel and others in text … many have become obsolete … it wasn’t working and didn’t scale.”

They needed a lean, flexible solution to unify legacy product data while enabling accurate execution. After evaluating options, they chose OpenBOM. The reasons they cited:

- Agile approach fitting internal processes.

- Ability to move rapidly from prototype to manufacturing.

- Simpler UI and lower overhead compared to heavyweight PLM tools.

With OpenBOM, the AMG team:

- Saved 8+ hours per week on engineering tasks previously spent reconciling BOMs.

- Enabled operations staff and casual users to adopt the platform quickly.

- Streamlined the path from design to manufacturing, boosting internal responsiveness.

As Owen Long put it:

“We rely on OpenBOM to help us manage a wide range of inputs … and quickly deliver an accurate product BOM to our manufacturing floor.”

Conclusion

So, when is the right time to move to OpenBOM?

It’s the moment your current tools stop being enough. When Excel sheets become error-prone, when CAD PDM silos block collaboration, when ERP data is always out of date, or when your suppliers can’t get the right information—those are the signals.

OpenBOM is the next step beyond ad-hoc processes. It provides:

- Cloud-native data model for CAD file management, digital BOMs, and catalogs.

- Seamless integrations with CAD, ERP, and supply chain tools.

- Collaboration across engineering, operations, suppliers, and customers.

- Foundation for the digital thread and AI-powered decision-making.

Additional Resources

If you want to explore further, here are some resources:

- OpenBOM PDM and CAD file management service

- OpenBOM xBOM service and digital thread

- OpenBOM ERP Integrations Circa 2025: From Seamless Sync to AI Agentic Workflows

- OpenBOM Data Model Explained

- Customer Story: Xponent Power

- Customer Story: TTM Technologies

Or, reach out to us directly at support@openbom.com to discuss your situation and learn how OpenBOM can fit your needs.

OpenBOM is easy to start and explore – REGISTER FOR FREE and check it out during 14 days of a trial or talk to our sales and support team.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.