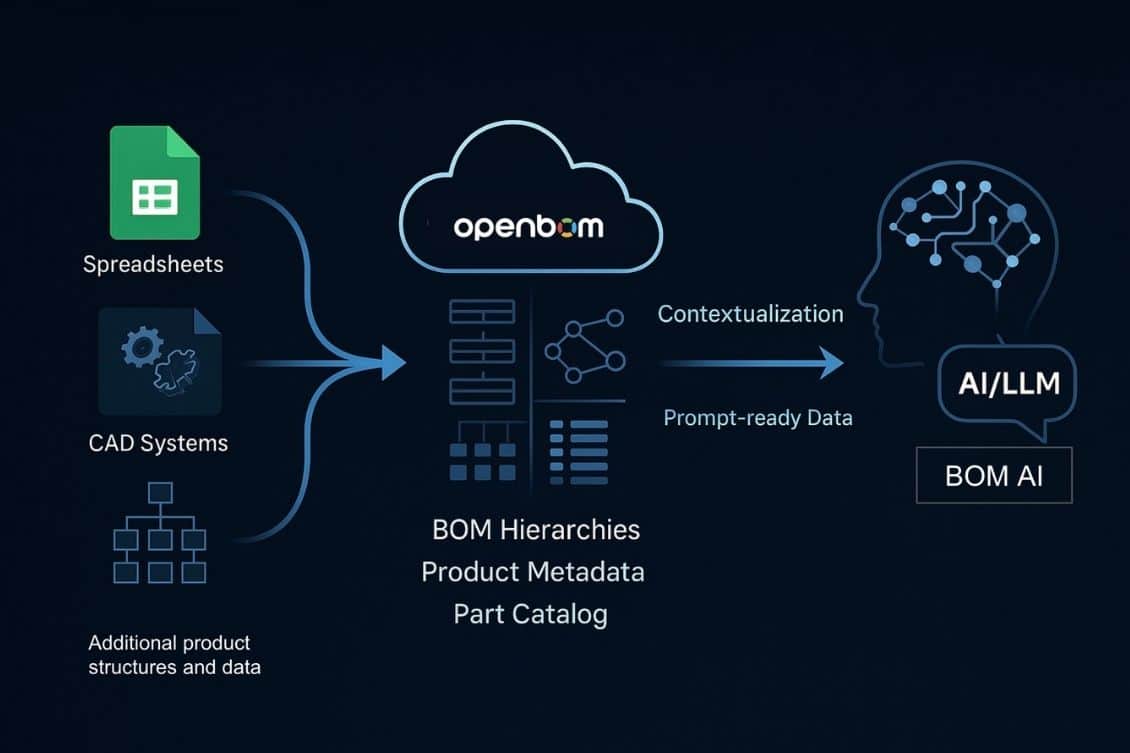

AI is changing how engineering and manufacturing teams think about data. The ability to ask intelligent questions and get meaningful answers depends not only on the AI model but, most importantly, on the quality and structure of the data it has access to.

That’s where OpenBOM comes in.

OpenBOM has always been more than just a tool to manage a bill of materials. It’s a cloud-native, multi-tenant service built to hold rich, structured product information – BOMs, part catalogs, vendor data, change history – all in one place. And with our latest update, we’re making it even easier to bring this data into the system and make it ready for AI.

Let’s talk about how the new multi-format, multi-level Excel import feature sets the stage for the future of AI in manufacturing.

Turning Spreadsheets into Structured Intelligence

Many companies still manage product data in Excel. It’s familiar, flexible, and completely disconnected. Only CEOs (Chief Excel Officers) know how the data in Excels is organized, connected, and can be used. The real challenge comes when you try to do something meaningful with those spreadsheets, like build a digital product structure or feed it into an AI workflow – 5 Reasons Why Your Boss Does’t Like BOM Excels.

There are so many conversations about AI these days, but many companies are completely missing the point that AI can be only built on a well structured data. OpenBOM online service allows your company to built a missing link in your AI project – structured data set of product information. By importing data from CAD systems, Excels, MRP/ERP and custom databases, OpenBOM graph-based model creates a product structure foundation for data intelligence.

The result is a complete, contextualized digital BOM built from the documents your team already relies on. This opens the door for better collaboration, more accurate planning, and seamless integration with downstream systems—including AI.

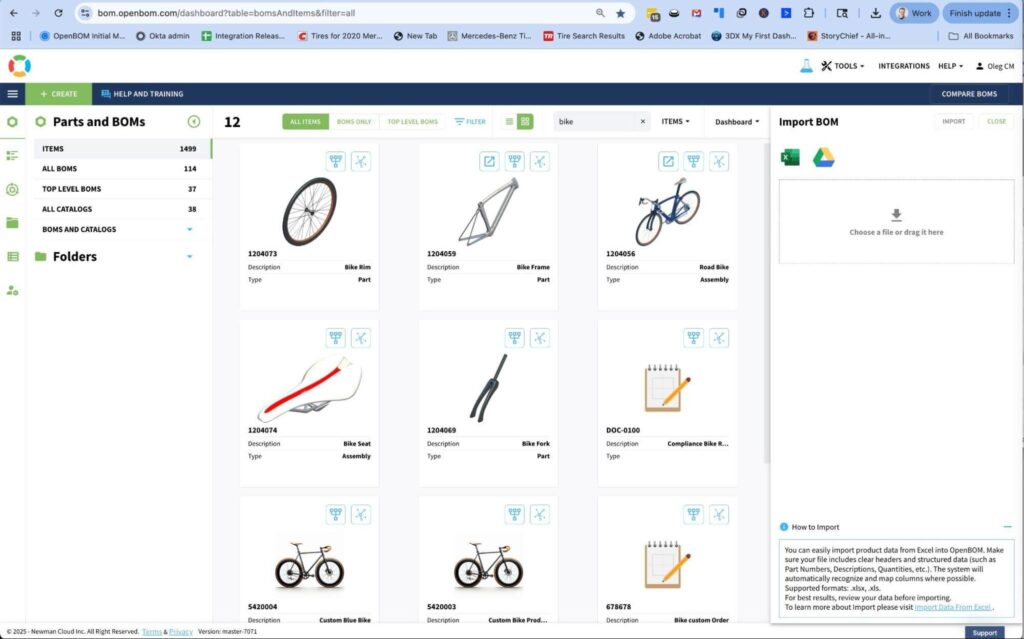

New Universal Import: Multiple Formats and Transforming Excel Files into Digital Product Structures

New OpenBOM import can understand different spreadsheet formats. Whether you’re dealing with flat part lists, deeply nested BOMs, or mixed tables from suppliers, OpenBOM intelligently maps the data, detects hierarchy, and automatically builds structured assemblies with correct part relationships and metadata. It also matches parts to existing catalog items or creates new ones on the fly—eliminating the need to retype or clean up data before use.

OpenBOM’s new import capability is a big step up in the ability to bring data seamlessly to OpenBOM. You can do it via user interface drag-n-drop, API, and (soon) via MCP protocol. Even before, OpenBOM import/export capabilities where user friendly allowing to data always being import/export. It is a huge step up now. New import lets you take existing Excel files, no matter how messy or inconsistent, and turn them into fully structured, multi-level BOMs in OpenBOM. Parent-child relationships? Preserved. Component metadata? Organized. Files? Attached. You don’t need to spend hours cleaning up your data – OpenBOM does the heavy lifting. In just a few clicks, you go from unstructured lists to a rich, hierarchical product model that actually makes sense.

Current OpenBOM release supports one of the most widely used formats exported by major PLM and ERP systems – index (x.x.x.) and level (N) formats. OpenBOM can import a complete BOM file, but also can build a structure by stages – importing BOM data, independely from catalogs, add more information to item data, attach files. OpenBOM flexible data model allows you to build the data model on the fly (via user interface, but also via API).

A Backbone for AI and LLMs

Here’s where it gets even more interesting. Once your product data is structured in OpenBOM, it becomes an ideal candidate for use with large language models and other AI tools.

Why? Because OpenBOM provides the context that AI needs.

Every part in OpenBOM is organized into catalogs with unique part numbers, supplier info, descriptions, and any other metadata you need. The xBOMs themselves are structured hierarchies that reflect the real-world relationships between components and subassemblies. You can build different BOM types – engineering, manufacturing, requirements, sales, maintenance, etc (you name them). This isn’t just data, but it’s context, and that’s exactly what powers useful, accurate AI interactions – it is a fuel for your structured prompts. (Note: we will talk about Tokenization and Language Models in the future articles, meantime, check why Structured Data is important for AI in my Beyond PLM article)

So instead of generic prompts, you can start asking AI very specific questions about your actual product. You can pull in subassemblies, track down part history, compare revisions, and much more—all because the underlying data is structured and contextual.

From CAD Design to BOM, Seamlessly

One of the key reasons OpenBOM is so effective as a product data platform is our integration with leading CAD tools. Whether you use SolidWorks, Onshape, Autodesk Fusion, or others, OpenBOM connects directly to your design environment and extracts the structure and metadata you need.

That means your BOM isn’t just manually typed in after the fact, it’s generated from the design itself, and then enriched with additional business context like supplier details, cost, and manufacturing notes.

This connection between design data and BOM context is incredibly powerful when you start thinking about intelligent systems. It allows AI to reason not just about what parts exist, but why they exist, how they’re used, and what alternatives might be possible.

Structured Data, Flexible Output

Once your data is in OpenBOM, you’re not locked into a single format or use case. You can export your BOMs as indented lists, flattened tables, or JSON through our REST API. We are coming with OpenBOM support for MCP (stay tuned) to turn OpenBOM into a conversational agent. This makes it easy to plug OpenBOM data into prompt templates, LLM training sets, or other downstream systems.

More importantly, OpenBOM maintains version control and can organize data in different lifecycle stages (requirements, engineering, manufacturing, sales, maintenance, etc). Read more about OpenBOM’s xBOM architecture. Every BOM and part can be traced through its history. So when you’re building prompts or running AI models, you can confidently refer to the exact version of the data that was current at a specific point in time. No ambiguity. No guesswork.

Ready for Automation, Ready for AI

If your team is already exploring AI automation – whether it’s retrieval-augmented generation (RAG), digital assistants, or intelligent document creation – OpenBOM’s data model and API provide the missing link. You get rich product data model, programmatic access to your BOMs, parts, hierarchies, and metadata in real time.

That means you can build intelligent agents that generate prompts on the fly, pull only the data they need, and respond to users with precision. OpenBOM account can be created online, the data is hosted in the cloud, it is secured and always available (different hosting options of OpenBOM platform are available). You can connect OpenBOM to your AI workflows and start delivering real engineering intelligence, not just static content.

Conclusion:

Companies are actively looking how to build AI applications and new innovative solutions. To do so, you need to have a digital infrastructure to manage information. While we are super excited about new LLMs and their capabilities, they are stateless. This is just a brain (an important, but only a brain). It lacks memory. To build efficient AI solutions you need to organize a memory with a product information that will serve your solution with the memory. It’s about transforming how we work with product data – from creation to collaboration to intelligence.

OpenBOM’s capability to import and organize product data make it easier than ever to structure product information in a way that’s clean, consistent, and AI-ready. Combined with our CAD integrations, version control, xBOM, export options, and open API, OpenBOM is laying the groundwork for the new generation of product lifecycle tools You’re not just digitizing a spreadsheet, but you’re building the foundation for intelligent design, manufacturing, and decision-making.

Coming soon: We’ll be sharing more practical examples of how to use OpenBOM data in AI prompts, generate engineering documents, and integrate with popular LLM frameworks. Stay tuned!

If you haven’t tried the new import yet, now’s the time. It’s not just a better way to manage BOMs, but it’s a smarter way to think about your data.

REGISTER FOR FREE to check OpenBOM during the trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.