Imagine a small but growing manufacturing company. The engineers are busy designing innovative products in CAD tools like SolidWorks or Autodesk Fusion. Once designs are ready, the team manually exports part lists into spreadsheets. Someone from operations then re-keys that information into Odoo ERP for purchasing and production planning.

The problem? Mistakes creep in. A wrong part number here, a missing revision there, and suddenly, procurement orders the wrong component. Manufacturing grinds to a halt while engineering scrambles to correct the mistake.

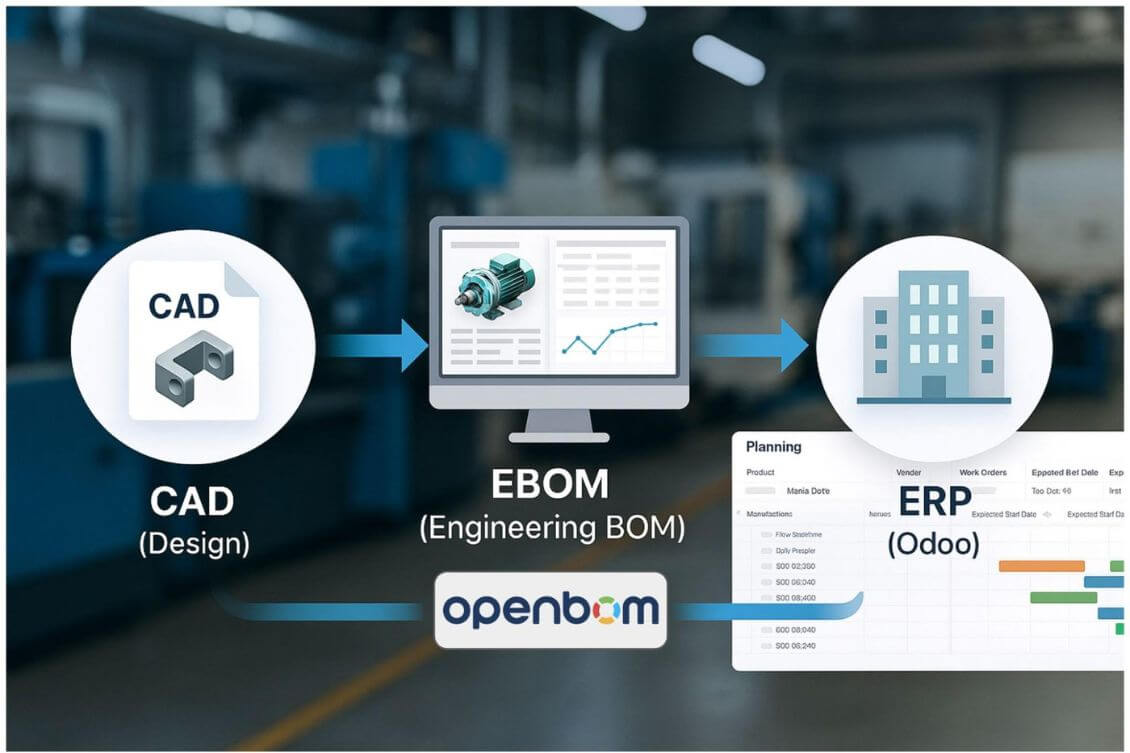

This story is familiar to many manufacturers. The root cause is simple: there’s no smooth connection between CAD, the Engineering Bill of Materials (EBOM), and ERP. That’s where OpenBOM’s integration with Odoo ERP comes in.

The Challenge of CAD to ERP Integration

Most companies want a direct link from CAD to ERP, but it rarely works well. Here’s why:

- Duplicate data entry – engineering enters once, operations enters again.

- Part number mismatches – ERP often requires different numbering rules.

- Version control issues – CAD revisions don’t sync properly with ERP.

- Procurement delays – without accurate EBOM, purchasing doesn’t know what to buy.

The missing link is the EBOM (Engineering Bill of Materials). EBOM acts as the structured bridge between design intent and business execution. OpenBOM specializes in managing EBOMs and synchronizing them seamlessly into Odoo.

Step 1: CAD to EBOM in OpenBOM

The first step in the workflow starts where engineers are most comfortable: inside CAD. OpenBOM integrates directly with leading design tools such as:

- SolidWorks

- Autodesk Fusion

- Onshape

- Inventor

- Others

Learn about all available OpenBOM Integrations.

With a few clicks, the CAD design structure is captured into OpenBOM. Instead of being a static spreadsheet, this becomes a live, structured BOM containing:

- Items and assemblies

- Part metadata (materials, properties, costs)

- Links to CAD files and revisions

- Supplier references if available

For complex assemblies, OpenBOM preserves the hierarchy and relationships. What used to be a manual export now becomes a traceable digital record.

Step 2: EBOM Management in OpenBOM

At first glance, it might seem tempting to connect CAD data directly to ERP. After all, engineers already have a complete design structure in CAD—why not just push it straight into Odoo and start purchasing parts?

The reality is more complicated. CAD data alone isn’t enough for ERP. ERP systems need structured, validated, and enriched data that goes beyond what CAD provides. That’s where the Engineering Bill of Materials (EBOM) comes in.

Why Not CAD → ERP Directly?

- CAD is design-focused, ERP is business-focused. CAD holds geometry, assemblies, and design parameters. ERP focuses on part numbers, suppliers, lead times, costs, and inventory rules. Directly sending CAD data to ERP skips this crucial translation step.

- Risk of incomplete or misleading data. CAD assemblies often contain reference components, placeholders, or virtual items that don’t belong in ERP.

- Different structures. CAD BOMs are hierarchical and mechanical; ERP BOMs need a flattened, procurement-ready structure.

- No validation stage. Without an EBOM, errors or missing data can flow straight into procurement, leading to costly mistakes.

The Role of EBOM in OpenBOM

The EBOM serves as the bridge between design intent and business execution. By capturing CAD data and transforming it into an engineering-focused BOM, OpenBOM provides a layer where data can be validated, enriched, and contextualized before it enters ERP.

In OpenBOM, the EBOM is not just a list of parts—it is a collaborative workspace where the whole team can contribute:

- Validation and Review. Engineers, procurement, and manufacturing can jointly review the BOM. Teams check that part numbers are consistent, metadata is accurate, and no items are missing.

- Multi-disciplinary Collaboration. Modern products are rarely just mechanical. OpenBOM allows combining mechanical components (from CAD) with electronics (PCBs, chips, connectors), and even software deliverables (firmware versions, licenses). This unified EBOM provides a holistic product view that ERP systems need.

- Combining Data Sources. EBOM can include vendor information, alternates, substitutes, and cost data pulled from catalogs, ensuring the BOM is procurement-ready.

- Change Control. Each EBOM revision is captured in OpenBOM, creating a clear history of what changed, when, and why.

EBOM as a Shared Collaborative Workspace

Think of OpenBOM as a digital meeting room where engineering, procurement, and operations gather around the same source of truth. Instead of passing Excel files back and forth, stakeholders log into OpenBOM to see the same EBOM, updated in real time.

- The mechanical engineer adds CAD-derived parts.

- The electronics engineer supplements the BOM with PCB assemblies and electronic components.

- The software team attaches software versions or licenses.

- The procurement team reviews sourcing options and validates vendor data.

- The manufacturing planner checks for feasibility and production readiness.

This process ensures that by the time the EBOM flows into Odoo ERP, it is not just a dump of CAD data—it is a validated, enriched, and multi-disciplinary engineering record ready for business execution.

In short, the EBOM is not just an intermediate step; it’s the collaboration hub that transforms engineering output into reliable, actionable manufacturing input.

Learn more about OpenBOM Collaborative Workspace technology and approach.

Step 3: Integration with Odoo ERP

Here’s where the OpenBOM ↔ Odoo connection delivers its biggest value. Once an EBOM is ready, it can be synchronized into Odoo ERP.

What happens in this step?

- Data Mapping: OpenBOM maps items, quantities, vendors, and sourcing information into Odoo’s product and inventory modules.

- Procurement: Buyers in Odoo can see exactly what parts are needed, their suppliers, and costs.

- Inventory: Stock levels are updated against engineering demand.

- Manufacturing Planning: Odoo generates work orders and schedules production based on the EBOM.

Instead of engineering handing over spreadsheets, the process is automated. When EBOM changes, updates can be pushed into Odoo, keeping ERP aligned with engineering.

This is more than just saving time—it’s eliminating errors that cost money and delay projects.

Watch a quick video about OpenBOM – Odoo integration preview

New OpenBOM – Odoo Integration User Guide

To help users get the most from the integration, OpenBOM provides a dedicated Integration User Guide. This resource explains how to configure the connection, map fields between systems, and synchronize data accurately.

The guide highlights best practices for preparing EBOMs—validating item properties, ensuring sourcing information is complete, and cleaning up data before pushing to Odoo. Following these steps reduces errors and builds confidence that ERP will reflect the true state of engineering.

By offering clear setup instructions, sync workflows, and error-handling tips, the guide shortens onboarding and minimizes guesswork. It ensures that the CAD → EBOM → ERP workflow works not just once, but repeatedly and reliably as products evolve.

For manufacturers adopting Odoo ERP, this guide is the roadmap to making OpenBOM the bridge between design intent and business execution.

Use Cases & Benefits

The OpenBOM ↔ Odoo workflow solves real problems for manufacturers.

1. Accuracy in Purchasing

ERP buyers get the right part numbers, quantities, and vendor details directly from the EBOM.

2. Reduced Manual Work

No one needs to retype BOMs into ERP. Engineering data flows automatically.

3. Collaboration Across Teams

Engineering, operations, and procurement share the same source of truth.

4. Faster Time-to-Market

By streamlining BOM transfer, companies can launch products quicker.

The Broader Perspective: Digital Thread & Growth

This integration is not just a point solution—it’s a step toward the digital thread.

The digital thread connects design, engineering, manufacturing, and supply chain data into one continuous flow. For SMBs and mid-size manufacturers, OpenBOM plus Odoo provides a lightweight but powerful foundation:

- Scalable: From a few dozen parts to thousands across supply chains.

- Flexible: Works across different CAD tools and Odoo modules.

- Future-Ready: Positioned for AI-driven insights, cost tracking, and supplier intelligence.

Where traditional PLM systems are too heavy and expensive, OpenBOM acts as an agile connector, keeping companies competitive.

Frequently Asked Questions

Q: What is an EBOM?

An Engineering Bill of Materials (EBOM) is a structured list of items, components, and assemblies that represent the design intent of a product. It originates from CAD but includes metadata useful for downstream processes.

Q: Why not connect CAD directly to ERP?

CAD tools aren’t designed for business workflows. ERP systems require different data structures (vendors, costs, inventory rules). EBOM in OpenBOM acts as the translator.

Q: How does OpenBOM integrate with Odoo?

OpenBOM provides a connector that synchronizes EBOM data—items, catalogs, BOM structures—into Odoo’s ERP modules. Documentation explains configuration, mapping, and workflows.

Q: Who benefits most from this integration?

Small and mid-size manufacturers, startups, and engineering-driven companies who use CAD and Odoo ERP but struggle with manual BOM transfers.

Q: Can OpenBOM work with other ERPs besides Odoo?

Yes. OpenBOM integrates with multiple ERP platforms (e.g., NetSuite, Dynamics 365, QuickBooks), but Odoo is especially popular among SMBs for its flexibility.

Conclusion: From Spreadsheets to Digital Flow

The days of re-keying BOMs into spreadsheets and ERP are numbered. Manufacturers who embrace the CAD → EBOM → ERP workflow gain accuracy, efficiency, and speed.

OpenBOM is the connector that makes this possible, ensuring that engineering data flows naturally into Odoo ERP for procurement, inventory, and manufacturing planning.

For companies looking to reduce errors, eliminate manual work, and build a true digital thread, the OpenBOM ↔ Odoo integration offers a practical and affordable solution.

👉 Learn more in the OpenBOM Odoo Integration Documentation or explore how OpenBOM can fit into your workflow today.

REGISTER FOR FREE to check OpenBOM and Odoo integration now.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.