In modern manufacturing, the ability to connect product data from engineering to enterprise systems is no longer a luxury—it’s a necessity. Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems are the backbone of manufacturing operations, but they often speak different languages. The handoff from engineering (where products are designed) to ERP (where products are purchased, manufactured, and shipped) is where inefficiencies and errors usually happen.

At OpenBOM, we’ve built an architecture specifically designed to bridge this gap. Our approach combines a modern cloud-native platform, powerful APIs, and a flexible Digital xBOM model that lets you consolidate, review, and approve product data before transferring it into any ERP system.

In this article, I’ll walk you through the key components of the OpenBOM architecture for ERP integrations, highlight some of our recent ERP connectors, and explain why this matters for your business.

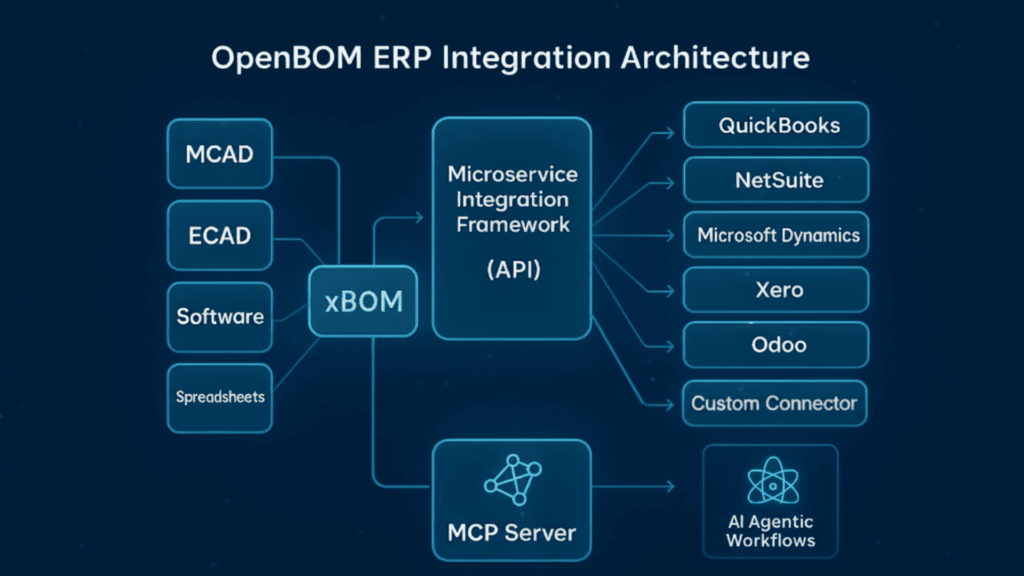

OpenBOM’s Robust Tech Stack for ERP Connectivity

Unlike legacy PLM and PDM systems that rely on brittle, point-to-point integrations, OpenBOM was designed from day one as a multi-tenant cloud-native platform. This matters because it allows us to offer modern, resilient, and extensible APIs to connect with other business systems—ERP included.

Some of the core technologies we leverage include:

- REST APIs and Webhooks: Enable two-way communication between OpenBOM and ERP. Product data doesn’t just move one way—it can be validated, updated, and synchronized in real time.

- ERP Connectivity Framework: A layer that normalizes data transfer, ensuring that ERP-specific requirements (field mappings, object definitions, workflows) can be configured rather than hard-coded.

- Microservices Architecture: Each integration is modular, so new ERP connectors can be built, deployed, and updated independently without disrupting other parts of the system.

Together, these elements form the backbone of OpenBOM’s ability to connect seamlessly with a wide variety of ERP systems, from SMB-focused accounting packages to large enterprise platforms.

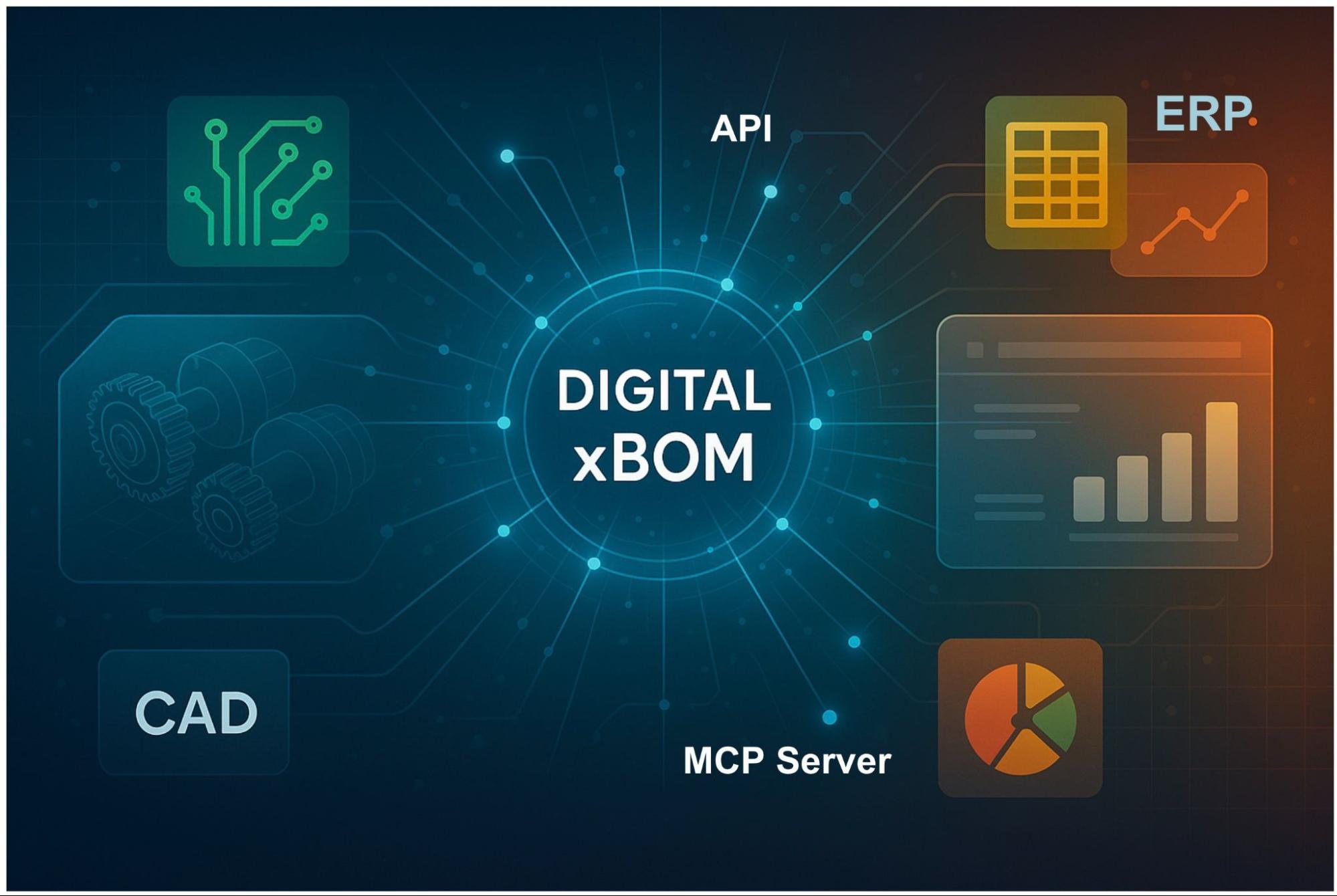

Digital xBOM: The Core of the Architecture

At the heart of our integration strategy lies the Digital xBOM. This isn’t just a Bill of Materials (BOM)—it’s a multi-view, multi-purpose data model designed to capture product definitions across engineering, manufacturing, procurement, and service.

Why does this matter for ERP integration?

Because sending raw engineering data straight into ERP is a recipe for mistakes. Engineers often work with prototypes, design alternates, or incomplete structures that are not ready for purchasing or manufacturing. ERP systems, on the other hand, expect finalized and approved structures with well-defined parts, quantities, and vendor assignments.

The Digital xBOM acts as the “buffer zone” between these two worlds. In OpenBOM, teams can:

- Consolidate BOM data from multiple CAD and design tools.

- Review and validate the structure for accuracy.

- Approve BOMs before releasing them downstream.

Only once this process is complete does the data flow into ERP. This ensures that ERP systems receive clean, accurate, and approved data—avoiding costly errors such as duplicate part numbers, incorrect quantities, or missing supplier information.

ERP Connectivity Framework and Pre-Built Connectors

Once a BOM is approved, the question becomes: how does it get into ERP?

That’s where OpenBOM’s ERP Connectivity Framework comes in. This framework provides the foundation for mapping OpenBOM data into ERP-specific structures, whether that means parts, assemblies, purchase items, or production orders.

The framework supports:

- Flexible Field Mapping: Define how OpenBOM properties (like part number, description, or cost) correspond to ERP fields.

- Data Transformation Rules: Handle differences in units, attributes, or formatting.

- Automated Workflows: Push BOM data to ERP with one click, or trigger updates via workflows and events.

On top of this framework, OpenBOM offers pre-built connectors for widely used ERP systems. These connectors simplify integration for customers who don’t want to start from scratch.

Examples of Recently Added ERP Integrations

OpenBOM is rapidly expanding its integration library. Over the past year, we’ve introduced new ERP connectors that cover a range of business needs—from accounting-centric systems used by small companies to full-scale ERP suites used by enterprises.

In addition to OpenBOM NetSuite integration, here are some of the most recent additions include:

- QuickBooks: Popular among small to mid-sized manufacturers, QuickBooks integration ensures that item and BOM data can flow directly into accounting and purchasing workflows.

- Odoo ERP: An open-source ERP used worldwide, Odoo integration enables smooth data synchronization between design and manufacturing.

- Xero: Similar to QuickBooks but especially strong in international markets, Xero integration makes it easier for global SMBs to connect product data to financial operations.

- Microsoft Dynamics 365 Business Central: For larger organizations, the Dynamics connector bridges engineering and finance, ensuring BOM data supports both manufacturing and financial planning.

- Visma ERP (NXT): Particularly relevant in the Nordic markets, this integration allows companies using Visma ERP to bring in product data directly from OpenBOM.

And this is just the beginning. More ERP integrations are coming soon, reflecting our commitment to supporting the diverse ERP landscape.

The key takeaway is that these connectors were not years-long projects—they were built and deployed quickly thanks to OpenBOM’s modular architecture and ERP Connectivity Framework.

Fast Addition of New ERP Connectors

For many manufacturers, the ERP system of choice isn’t one of the “big names.” Instead, it might be a specialized or regional ERP tailored to their industry. That’s why we designed our architecture to allow new ERP connectors to be developed quickly.

As part of the OpenBOM Enterprise Subscription, customers gain access to our engineering and integration teams, who can work with them to:

- Develop new connectors for niche ERP systems.

- Customize data mappings and workflows to their specific needs.

- Ensure compliance with regional or industry-specific requirements.

The speed and flexibility of this process are possible because of OpenBOM’s microservices approach. Each connector is a separate service that can be built, tested, and deployed without disrupting existing customers.

MCP Server and Agentic Workflows

Looking beyond today’s integrations, OpenBOM is also preparing for the next generation of digital workflows through the MCP (Model Context Protocol) Server.

MCP Server makes OpenBOM data accessible in a way that enables advanced analytics, custom workflows, and even AI-driven “agentic” processes. For ERP integration, this unlocks powerful new possibilities:

- Cost Roll-Ups: Combine data from OpenBOM (quantities, materials) with ERP (pricing, supplier contracts) to generate accurate cost estimates.

- Inventory Planning: Cross-reference BOM requirements with ERP inventory to flag shortages before they become problems.

- Procurement Optimization: Use agents to identify alternate suppliers, substitute parts, or negotiate pricing based on historical ERP data.

In short, MCP Server allows organizations to move beyond simple “data transfer” and into intelligent, context-aware workflows that bring together the best of PLM and ERP worlds.

Why This Matters

Integrating PLM and ERP has traditionally been one of the most painful parts of manufacturing IT. Legacy systems required custom middleware, brittle integrations, and endless consulting hours to get right—and even then, the results were fragile.

OpenBOM changes this by providing:

- A robust, modern tech stack built for the cloud.

- The Digital xBOM as a clean handoff point between engineering and ERP.

- A flexible ERP Connectivity Framework with pre-built connectors.

- Rapid development of new ERP connectors as part of Enterprise Subscription.

- MCP Server for advanced workflows and AI-driven integration scenarios.

The result is an architecture that simplifies, accelerates, and de-risks ERP integration. Whether you’re a small company running QuickBooks or a large enterprise with Dynamics 365, OpenBOM gives you the tools to connect your product data reliably and efficiently.

Conclusion

Manufacturing companies can no longer afford to treat PLM–ERP integration as an afterthought. Product data needs to flow seamlessly from design to production to finance, and errors in this process cost time, money, and customer trust.

OpenBOM’s architecture for ERP integrations delivers a modern, flexible, and future-proof solution. By leveraging the Digital xBOM, ERP Connectivity Framework, and MCP Server, we enable manufacturers to consolidate, validate, and transfer product data with confidence.

Ready to modernize your PLM–ERP integration? Contact us at support@openbom.com to learn more or schedule a demo.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.