Every manufacturer eventually faces the same problem: engineering and operations live in different systems, yet both depend on the Bill of Materials (BOM). Engineers use tools like CAD and product data management systems to design and define products. Operations teams, on the other hand, need that same information inside an enterprise resource planning (ERP) platform like Microsoft Dynamics 365 Business Central to drive purchasing, costing, and production.

Historically, bridging these worlds has been painful. Teams often export spreadsheets from engineering systems, clean them up, and re-enter data manually into ERP. This introduces errors, causes delays, and creates a constant cycle of reconciliation between systems.

OpenBOM was built to give engineers and product managers a flexible, cloud-native way to manage and collaborate on BOMs.

With the new OpenBOM integration for Microsoft Dynamics 365 Business Central, the next step is here: a direct, configurable connector that transfers structured product data into ERP quickly and accurately. In this article, I’ll walk through what the integration does, how it works, and why it matters, using a real demonstration from OpenBOM’s VP of Product, Steve Hess.

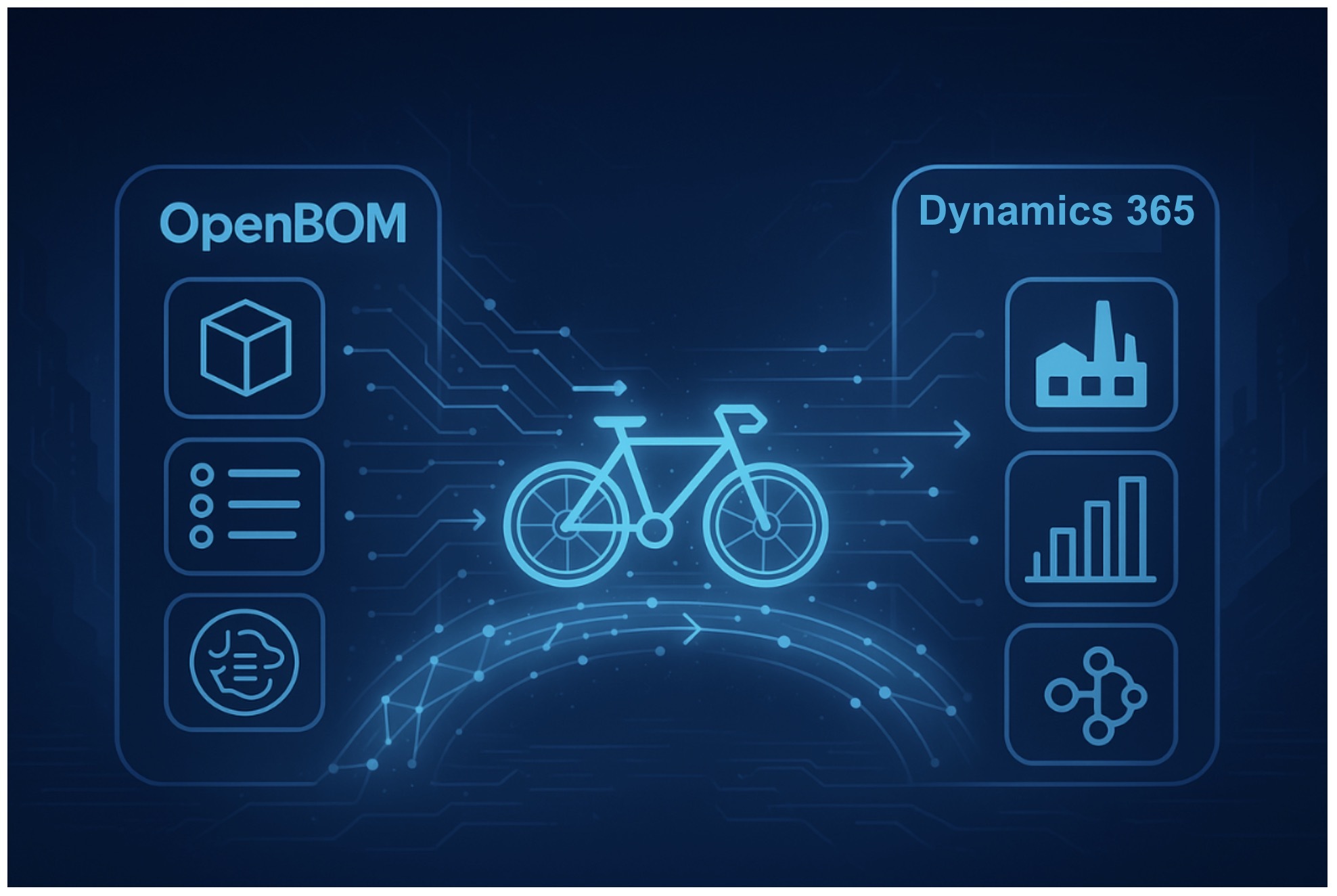

What the Integration Does

The OpenBOM–Microsoft Dynamics 365 Business Central connector is designed to eliminate the need for intermediate spreadsheets or custom IT projects when moving BOM data. Instead of relying on manual export and re-entry, the connector allows you to send data directly from an OpenBOM environment into Dynamics 365 Business Central with just a few clicks.

At its core, the integration supports three things:

- Data fidelity. Multi-level BOMs, including subassemblies and components, transfer without losing their structure.

- Attachments and metadata. Documentation, STEP files, PDFs, images, and other property data can move alongside the BOM.

- Configuration control. Users decide which properties and files to export, ensuring Dynamics 365 Business Central receives exactly the data it needs to support downstream processes.

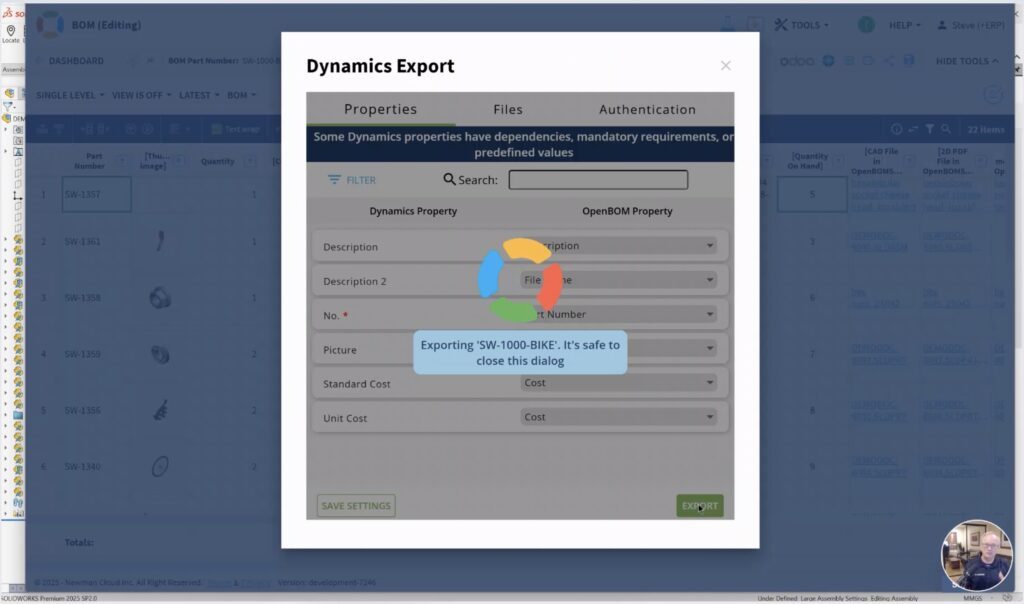

The process is straightforward. Inside OpenBOM, a user prepares a BOM—whether for a prototype assembly or a production-ready product. When ready, the user selects the Microsoft Dynamics 365 Business Central connector option.

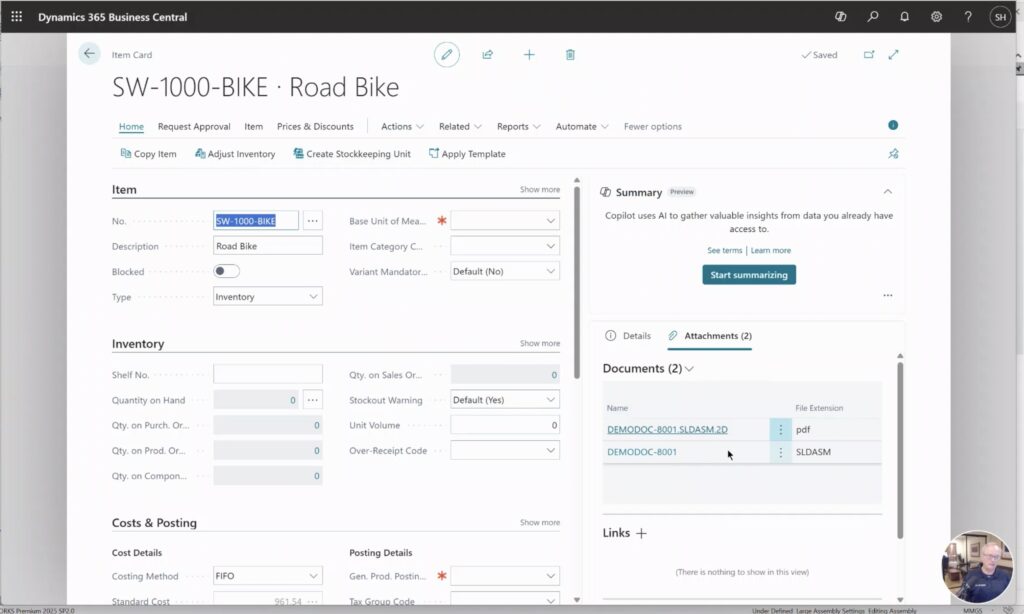

OpenBOM packages the BOM, applies mapping rules, and sends the data to Dynamics 365 Business Central. Once the transfer completes, the user receives a confirmation with a link to the newly created item inside ERP.

This workflow shifts the integration from something that traditionally required IT expertise to something engineers and operations staff can run directly.

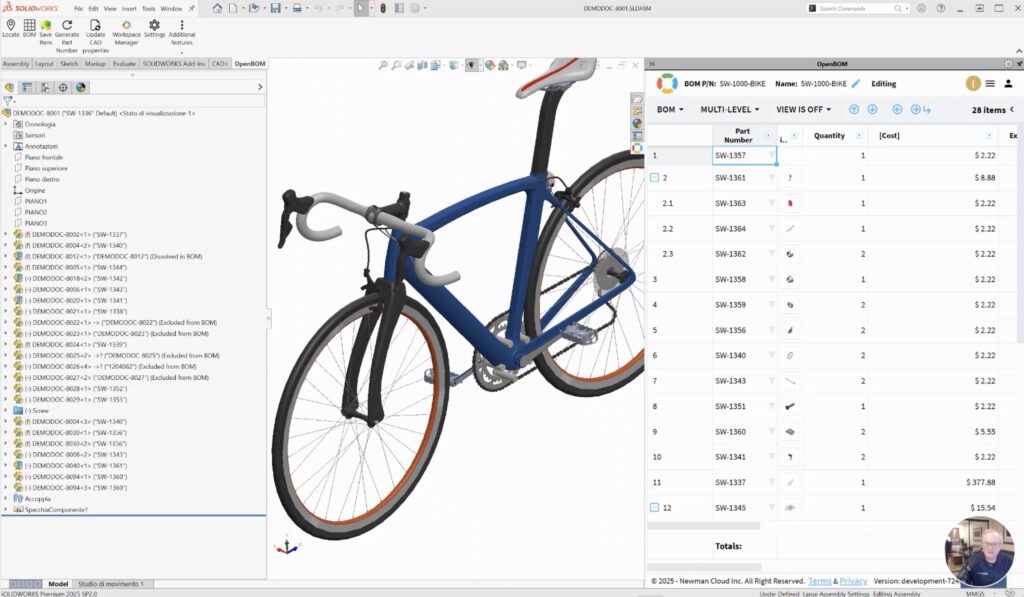

A Preview with a Road Bike BOM

To see the integration in practice, Steve Hess walked through a demonstration using a road bike assembly. This example highlights both the technical mechanics of the connector and its value in a realistic product scenario.

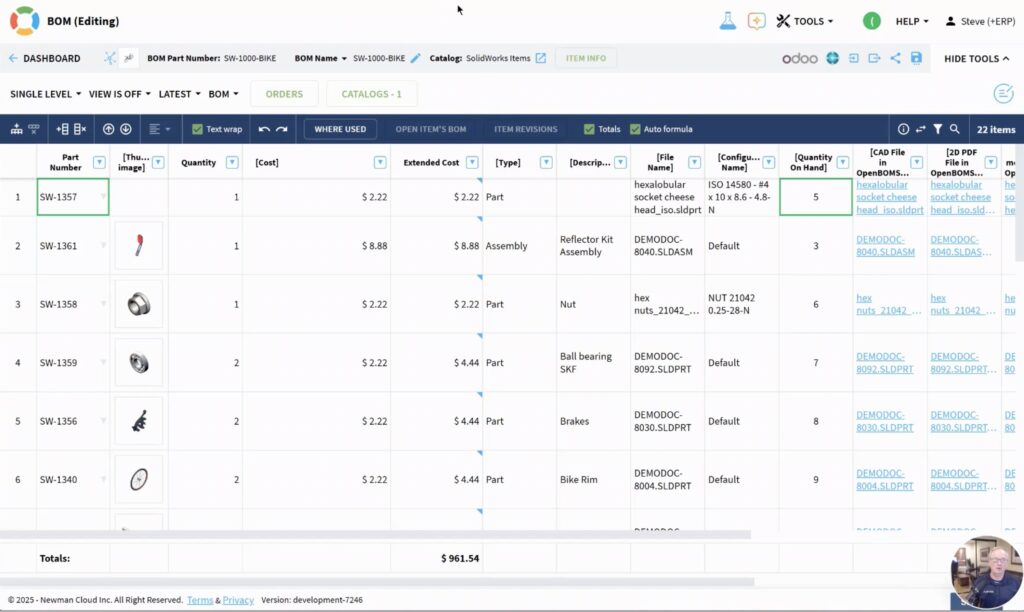

Inside OpenBOM, Steve began with a complete multi-level BOM for the road bike. At the top level sat the bicycle itself, while beneath it, each subsystem was broken down: frame, wheel assemblies, drivetrain, cockpit, and accessories. Each component contained detailed property data such as cost, part number, and supplier, along with attached STEP files for manufacturing and PDFs for reference. Thumbnail images helped make the structure more visual.

Steve modified a few costs and added a component, showing how OpenBOM updates the structure in real time. Then, with the BOM finalized, he activated the Dynamics 365 Business Central connector. OpenBOM packaged the full structure, applied the configured property mapping, and pushed everything to Microsoft Dynamics 365 Business Central.

Inside Dynamics 365 Business Central Business Central, the road bike assembly appeared with the same multi-level structure intact. The top-level bike was visible as an item, and drilling down into subassemblies revealed the frame, wheels, and drivetrain with all related components. Supporting documents, STEP files, and images were now accessible directly in Dynamics 365 Business Central, tied to the right parts. The demonstration made clear that what started in engineering was preserved all the way into ERP without manual intervention.

Watch the video with the demo:

How the Integration Works

Under the hood, the connector uses OpenBOM’s data model to create a structured export package. Properties from OpenBOM are mapped to Microsoft Dynamics 365 Business Central fields through a configuration step, which gives users flexibility to define what data is relevant for their ERP workflows. For example, cost, supplier, and description fields in OpenBOM can be aligned with Dynamics 365 Business Central purchase and accounting fields, while part numbers and thumbnails ensure traceability.

The connector also handles file management. If a component has associated PDFs, CAD derivatives, or STEP files, those are included in the transfer. This ensures that ERP users—often buyers or production planners—have access to the same documentation that engineering relied on.

One of the subtle but important aspects of the connector is automation. After a user selects the connector and initiates the transfer, the process runs in the background. Users don’t have to manually upload files or verify data line by line. When the transfer is complete, OpenBOM provides confirmation and a direct link to the item in Dynamics 365 Business Central, making it simple to continue the workflow.

Why This Matters

On the surface, moving BOM data from one system to another may seem like a tactical step. But the implications for product development and manufacturing are significant.

The first benefit is accuracy. Every time BOM data is handled manually, the risk of mistakes grows. A missed component, a mistyped cost, or an outdated drawing can all create downstream problems in purchasing or production. Automating the transfer between OpenBOM and Dynamics 365 Business Central reduces those risks by ensuring the data in ERP reflects the current engineering definition.

The second benefit is efficiency. Manual processes take time, and teams often end up reconciling mismatches between spreadsheets and ERP records. By cutting those steps, the connector accelerates the engineering-to-operations handoff. For companies working under tight development timelines or managing complex supply chains, even small time savings can add up.

The third benefit is consistency across systems. BOMs are not just flat lists; they are structured representations of how products are built. Preserving that structure across engineering and ERP means that all teams—from design to purchasing to manufacturing—share the same view of the product. This is critical for maintaining alignment as products evolve.

Beyond these immediate benefits, the integration also supports a longer-term goal: building a digital thread. The digital thread is the idea of connecting product data across its lifecycle, from initial design through manufacturing and beyond. By linking OpenBOM’s BOM management with Microsoft Dynamics 365 Business Central ERP, companies move one step closer to that connected backbone, reducing silos and improving collaboration across functions.

Value Proposition for Teams

For engineering teams, the value lies in being able to focus on design and product definition without worrying about how that data will reach ERP. They can be confident that what they create in OpenBOM will arrive in Dynamics 365 Business Central intact.

For operations and manufacturing teams, the value comes from receiving accurate, complete information in the system they use daily. Buyers see costs and suppliers without needing to chase down engineers. Production planners have access to up-to-date STEP files and PDFs directly in ERP. The integration supports smoother collaboration between functions that historically struggled to stay aligned.

For IT and system administrators, the value is in simplicity. Many integrations between engineering and ERP require middleware, custom development, or ongoing maintenance. The OpenBOM–Dynamics 365 Business Central connector avoids these complications by embedding the process directly in OpenBOM’s interface. That lowers cost and reduces reliance on custom code.

Conclusion

The OpenBOM integration with Microsoft Dynamics 365 Business Central is a technical update with a clear purpose: enable seamless transfer of BOMs, attachments, and properties from engineering to ERP. By preserving structure, supporting multi-level assemblies, and automating the transfer process, the connector eliminates manual re-entry and helps teams work from a consistent source of truth.

The road bike demo from Steve Hess illustrated the process clearly. A detailed BOM with costs, documents, and subassemblies was prepared in OpenBOM, exported via the connector, and appeared in Dynamics 365 Business Central exactly as intended. That demonstration makes the value of the integration tangible: fewer errors, faster workflows, and better alignment between engineering and operations.

As manufacturers continue to push for efficiency and digital connectivity, integrations like this one become essential. They not only save time in the short term but also contribute to the longer-term goal of creating a connected product lifecycle.

If you have questions about the OpenBOM–Microsoft Dynamics 365 Business Central integration or want to explore how it could fit into your environment, please contact us at support@openbom.com.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.