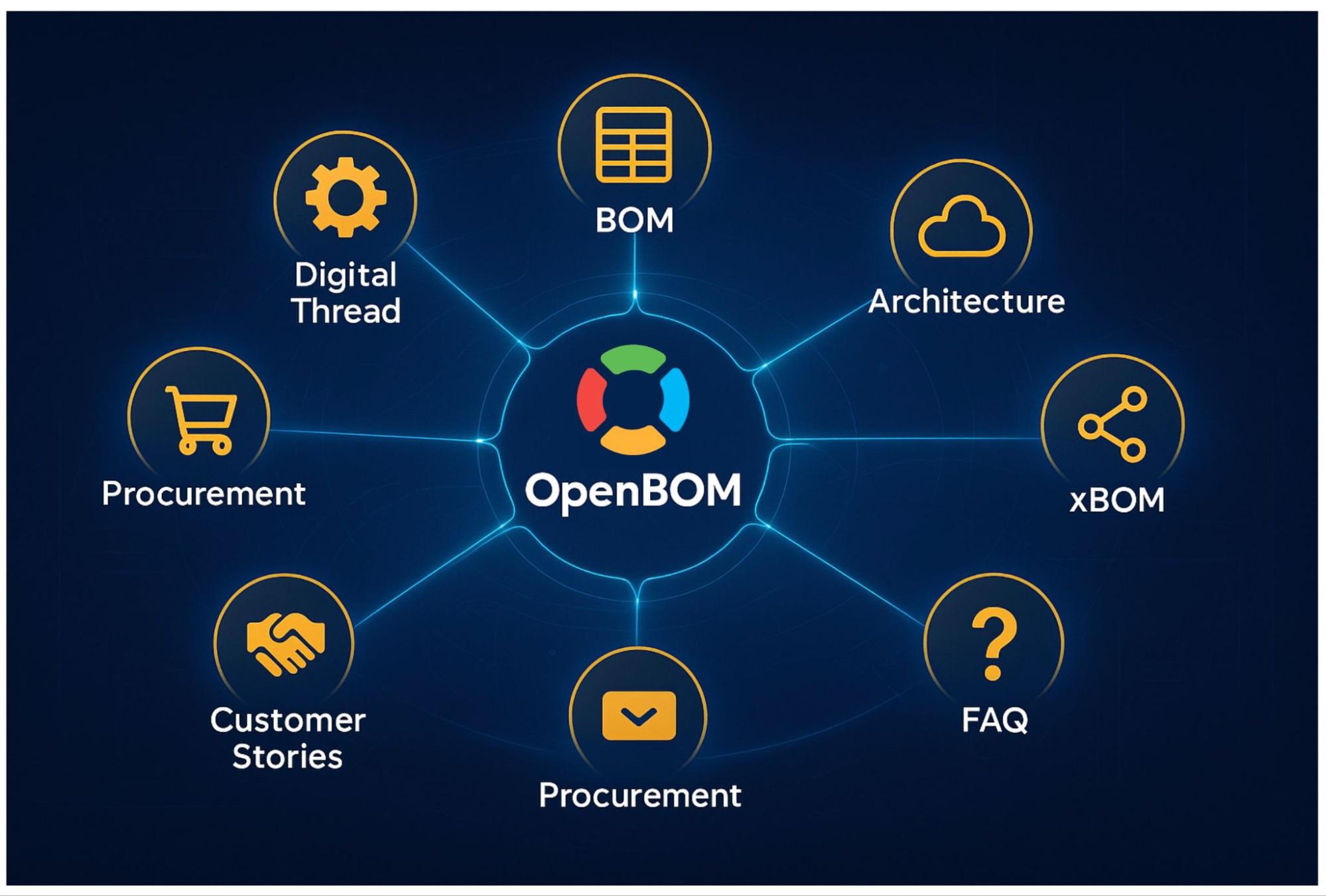

When I began the 30-Day OpenBOM Challenge, my goal was simple — to create a clear, practical guide for anyone who wants to understand how OpenBOM works and why it exists. Each day explores a different aspect of the platform, from architecture and xBOM modeling to real-world customer stories.

The first week, Orientation & Core Value, set the foundation. It introduced the ideas, technologies, and human challenges that shaped OpenBOM — and why thousands of engineers and manufacturers are choosing it as their modern digital thread platform.

Let’s recap the first seven days.

From Chaos to Clarity (Days 1–2)

Most companies start small — an engineer builds a product, a spreadsheet tracks the BOM, and soon enough, there are ten versions of that spreadsheet floating around the company.

This is how every digital-thread story begins: with Excel chaos.

Day 1: Welcome to OpenBOM 2025 – The Digital Thread for Modern Manufacturing introduced the bigger picture. Modern manufacturing requires a continuous digital thread — a flow of information that connects design, manufacturing, and procurement. OpenBOM’s mission is to make that thread accessible to everyone, not just large enterprises with complex PLM systems.

Day 2: Why BOM Still Matters – From Excel Chaos to Connected Product Data looked deeper into the heart of every product — the Bill of Materials. It explained why the BOM remains the essential bridge between engineering and business, and why managing it in spreadsheets inevitably leads to errors, version conflicts, and lost productivity.

A connected BOM isn’t just more efficient — it becomes a single, living representation of your product.

The Foundation: Cloud-Native and Graph-Based (Day 3)

If Week 1 had a technological heart, Day 3 was it.

OpenBOM Architecture Explained – Multi-Tenant, Graph-Based, Cloud-Native, Collaborative revealed what makes OpenBOM fundamentally different from traditional PLM platforms.

Instead of single-tenant SQL databases designed in the 1990s, OpenBOM runs on a multi-tenant microservice architecture, built for the cloud from day one.

At its core lies a graph-based data model — flexible, relational, and perfect for representing complex products that span disciplines and lifecycles. This architecture enables real-time collaboration, scalability, and security without the heavy IT burden of legacy systems.

And the story doesn’t end there. OpenBOM’s MCP Server and AI readiness lay the groundwork for the next evolution — intelligent, agentic workflows that can reason about your product data.

The xBOM Architecture (Day 4)

As products evolve, they no longer belong to a single discipline. Mechanical assemblies are filled with electronics, embedded software, and cloud services — each managed in different tools.

From PDM to xBOM – The New Product Structure Model introduced the concept of xBOM architecture, a graph-based model that unifies engineering, manufacturing, and service BOMs without duplication.

Unlike traditional PDM systems where EBOMs are isolated and static, xBOM allows multiple, synchronized views of the same product — each representing a specific lifecycle perspective. Mechanical engineers see their assemblies, manufacturing teams see flattened MBOMs, and service teams access spare-part BOMs — all connected through one shared product memory.

It’s a subtle but radical shift: from managing files to managing knowledge.

Connecting Engineering to Procurement (Day 5)

Even with the best CAD and PDM tools, the biggest operational pain often sits between engineering and purchasing. Misaligned part data, inconsistent revisions, or unclear quantities can turn production planning into chaos.

How OpenBOM Bridges CAD, BOM, and Procurement in One Workspace explored how OpenBOM eliminates that gap by linking design and business data in real time.

Using native CAD integrations — SolidWorks, Fusion, Onshape, Altium, and others — OpenBOM automatically generates BOMs directly from CAD assemblies and connects them with catalogs, vendors, and cost data. Procurement and engineering work from the same structure, reducing mistakes and speeding up ordering.

The post featured FenceQuip’s story, a manufacturer that transformed its purchasing process with OpenBOM.

As they put it:

“Engineering and purchasing operated in silos… mistakes were caught too late.”

With OpenBOM, FenceQuip turned data chaos into connected intelligence — fewer errors, better planning, and faster production.

Customer Proof: Real Teams, Real Results (Day 6)

Technology alone doesn’t prove value — people do.

Customer Snapshot – 5 Stories How Companies Moved from Spreadsheets to OpenBOM shared five real stories of manufacturers who decided to modernize their data management.

- VarTech Systems saves two hours of engineering time every day and eliminated costly ordering errors. “It’s all about the mistakes we don’t make.”

- RfIDEAS uses OpenBOM to communicate with contract manufacturers, consolidating all product data in one cloud workspace.

- SOLWR integrated OpenBOM with Onshape to give every team live access to their BOMs without email or Excel updates.

- Pyka, a pioneer in autonomous electric airplanes, replaced Google Sheets with OpenBOM to synchronize engineering and manufacturing data.

- Xponent Power moved from disconnected spreadsheets to a structured, cloud-based system that now anchors its entire engineering-to-procurement process.

Across industries, the message was consistent: OpenBOM replaces confusion with clarity.

Removing Barriers for New Users (Day 7)

The first week ended with practical help for newcomers.

FAQ – 10 Common Questions New Users Ask About OpenBOM answered the most frequent onboarding questions — from licensing and CAD integrations to data import, security, and ERP connectivity.

It also highlighted that OpenBOM’s open philosophy means no black boxes: pricing is transparent, onboarding is simple, and support is human. Whether you’re starting with a trial or an enterprise deployment, everything is designed to scale with your needs.

Core Value: The OpenBOM Philosophy

The first seven days built more than an introduction — they revealed a mindset. OpenBOM exists to make engineering data usable for everyone.

It connects people, tools, and processes through a flexible, multi-tenant, graph-based platform. It transforms static spreadsheets into living product structures that drive collaboration, traceability, and intelligence.

Where traditional PLM focuses on control, OpenBOM focuses on connection. Where legacy systems lock data away, OpenBOM opens it — across engineering, operations, and supply chain.

That openness isn’t just in the name — it’s the foundation for the next decade of digital manufacturing.

Conclusion and Week 2 Preview – Product Deep Dive (Highlights)

If Week 1 explains why OpenBOM matters, Week 2 will show how it works. Next week, we move from concept to practice. Week 2 will explore how OpenBOM’s key features and workflows actually work together in real-world scenarios — from PDM in the browser to SmartSync for CAD-to-cloud collaboration and procurement planning.

We’ll look at how engineers check in/out designs, manage revisions, generate xBOM views, and calculate real-time costs — all inside one connected platform.

Every manufacturing company, large or small, faces the same truth: the data that defines your product is the data that defines your business.The sooner you connect it, the faster you can innovate.

That’s the journey we’ve started with OpenBOM’s 30-day challenge — and we’re only just beginning.

Stay tuned for Week 2, where we’ll dive deep into the product and show what digital transformation looks like in action.

Meantime REGISTER FOR FREE and check in practice how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.