As we step into the last quarter of 2025, I’m excited to start something special today — a 30-day blogging journey about OpenBOM. Think of it as a self-contained learning path for anyone who’s curious about OpenBOM but has never had a proper introduction.

A New 30-Day Blogging Journey

Over the next month, we’ll walk through the entire story step by step. We’ll begin with the basics, then explore the product’s core features, look at its architecture, talk about why it matters in the current PLM landscape, and share real customer stories as well as what’s coming next. My hope is that by the end of this series you’ll have a clear and practical picture of OpenBOM 2025 — what it is, what problems it solves, and why we believe it represents the future of the digital thread for manufacturing.

Why So Many Teams Still Live in File, Email and Spreadsheet Chaos

Let me start with a familiar scene. Imagine a 20-person manufacturing team developing a new robotic assembly.

Engineering keeps CAD files on a shared network drive. Bills of Materials are managed in Excel. Emails fly back and forth between design, procurement, and suppliers. Each group edits its own copy of the spreadsheet, so by the time an order is placed there may be three slightly different versions of the BOM in circulation. A few part numbers don’t match. Some revisions are out of date. The result: late orders, last-minute fixes, missed deadlines, and plenty of frustration.

If that sounds familiar, it’s because this is still the daily reality for thousands of small and mid-size manufacturers in 2025.

Despite all the progress in CAD and ERP, the data that connects them is often still held together by fragile spreadsheets and emails. That gap between engineering intent and actual purchasing decisions is where cost overruns and delays quietly creep in.

2025: The Need for a Real Digital Thread

The pressure on manufacturers keeps growing. Product cycles are getting shorter, customers demand more variants, and teams are no longer sitting in one building — they’re distributed across geographies, suppliers, and contract manufacturers. Supply chains have become deeper and more complex just as component availability has become more volatile.

Traditional PDM and PLM systems were designed decades ago for a very different world. Most of them are still tied to on-premise deployments, require heavy customization, and don’t adapt well to distributed cloud-connected workflows. What modern teams really need is a true digital thread — a single, reliable flow of product data that can connect CAD, BOM, procurement, and every downstream process in real time.

Introducing OpenBOM: A Multi-Tenant, Cloud-Native, Graph-Based, AI-Enabled Platform

That’s exactly the challenge we built OpenBOM 2025 to address.

OpenBOM today is a multi-tenant, cloud-native, graph-based, AI-enabled data-management platform that brings together three essential capabilities for modern manufacturing.

- The first is collaborative PDM — lightweight file and version management designed for distributed engineering teams natively using cloud as a platform.

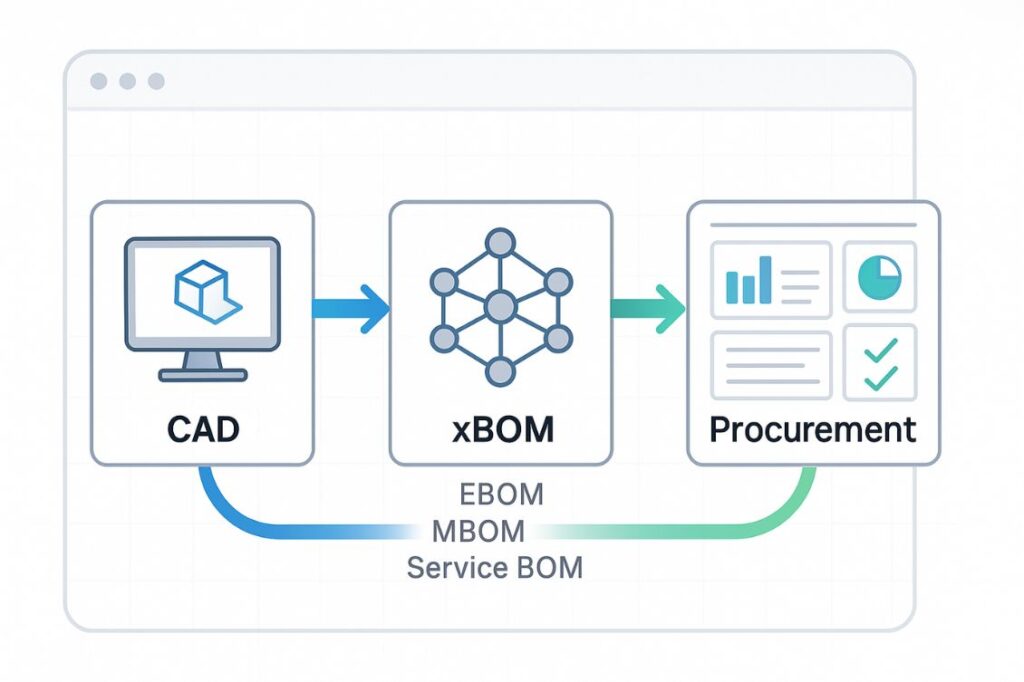

- The second is the xBOM service, which provides a flexible graph-driven product structure so that engineering BOMs, manufacturing BOMs, service BOMs, configurations and other views can all live in one consistent data model without duplication.

- The third, and newest, is the MCP Server and AI-powered engineering workflow and decision support. The MCP — short for Model Context Protocol — makes product data understandable to AI agents. This is what enables the new OpenBOM AI Agent to flag BOM inconsistencies, recommend alternates or substitutes, compare cost scenarios, and help teams make better decisions right where the data lives.

What makes OpenBOM stand out is that it feels as approachable as a spreadsheet, yet under the surface runs on a secure multi-tenant graph-based “product memory” that powers real-time collaboration today and paves the way for agent-driven workflows tomorrow.

Our Core Approach

OpenBOM was designed from day one to be open and connected. It integrates directly with the leading CAD tools — Autodesk Fusion, SolidWorks, Onshape, Altium and others — so that BOMs are generated automatically and stay in sync with the design data.

Its multi-view product structure means you can maintain engineering, manufacturing, service, or cost perspectives of the same product without copying and pasting data between systems.

The interface itself is as familiar as working in a cloud-spreadsheet: everyone can see live updates and collaborate in real time, whether they’re in the next room or on another continent.

Underneath it all sits a graph-based product memory that links everything together and is ready for smarter validations, contextual insights, and AI assistance.

Why It Matters

Companies adopting OpenBOM often tell us the first change they notice is simply speed and clarity. CAD data flows straight into structured BOMs; there are fewer manual errors; quantity roll-ups and supplier choices become visible earlier; release cycles shrink because everyone works from the same source of truth. These gains add up quickly to less rework, better cost control, and more predictable production.

2025 Momentum and What’s Next

This year has been particularly exciting. We introduced SmartSync to make CAD-to-cloud file handling more robust, added Object References and Linking to strengthen the digital thread across related items, and launched the AI Agent in private beta, which starts to make the promise of invisible, context-aware workflows a reality.

All these efforts reflect our core vision: to make product data work for people, instead of forcing people to work around rigid systems.

Conclusion and Join the Journey

Over the next 29 posts in this series, I’ll unpack each of these pieces — from xBOM and procurement planning to part numbering, digital-thread modeling, and agent-driven decision support.

If your team still lives in spreadsheets or you’re re-evaluating your PLM strategy, I invite you to follow along. My goal is to give you a clear, ground-level understanding of how OpenBOM 2025 can help you modernize your product data workflows and prepare for the next wave of AI-assisted engineering.

Let’s get started. REGISTER FOR FREE for OpenBOM to check this out and start getting emails about OpenBOM’s next 29 articles.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.