Every manufacturer has experienced it – the frustration of watching a carefully designed product run into unexpected delays or budget overruns, not because the engineering team failed, but because the engineering information couldn’t reach the people who needed it most.

Introduction – OpenBOM Aha Moment

When new OpenBOM users start exploring the platform, there’s often an “aha moment.” It’s the realization that the greatest productivity boost isn’t about controlling CAD models or generating a perfect BOM. It’s about making engineering information instantly available to the business – especially procurement.

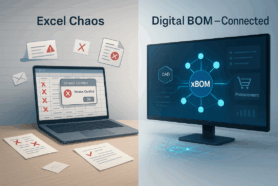

Historically, engineering and procurement have worked in separate silos. Designs lived inside CAD models. Procurement relied on emails, PDF drawings, and exported spreadsheets to figure out what to buy, when to buy it, and how much to order. The gap between these two worlds has been the root cause of countless errors, delays, and unnecessary costs.

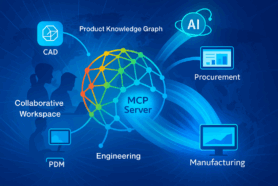

OpenBOM was built to open engineering data to the entire organization, enabling a seamless digital thread that connects CAD, BOM, inventory, and procurement in a single collaborative workspace. This post explains why bridging this gap is often the most important step in digital transformation for manufacturing businesses.

The CAD-to-Procurement Gap – Where Mistakes and Delays Happen

The handoff from engineering to procurement is one of the most error-prone parts of the manufacturing process.

In a typical scenario, an engineering team designs an assembly in SolidWorks or Autodesk Fusion and then exports a spreadsheet BOM. Multiple CAD systems means multiple spreadsheets. Those spreadsheets are emailed to procurement, often with little context, no revision history, no change tracking, and no live link to CAD. No derivative files too. Procurement then manually enters the data into online ordering systems or ERP or their own spreadsheets.

While the engineers keep iterating and making changes, procurement is often working from stale data.

This disconnect creates a breeding ground for mistakes:

- Wrong quantities get ordered.

- Outdated revisions slip into production.

- Parts are over-ordered, wasting cash and storage space.

- Or worse—critical items are under-ordered, halting production on the shop floor.

One of our customers, FenceQuip, lived through this pain before moving to OpenBOM. Here’s how they described it:

“Engineering and purchasing operated in silos, with valuable design data stuck inside CAD models while procurement teams scrambled to interpret spreadsheets and emails to determine what to order. Sometimes, mistakes were caught too late—materials were either over-ordered, increasing waste and tying up capital, or under-ordered, causing production delays.”

FenceQuip’s experience is not unusual. Many small and mid-sized manufacturers lose weeks of time and thousands of dollars each year simply because they lack a connected process that ties engineering changes directly to procurement actions.

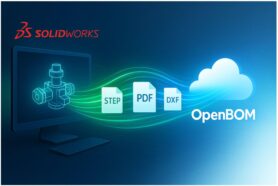

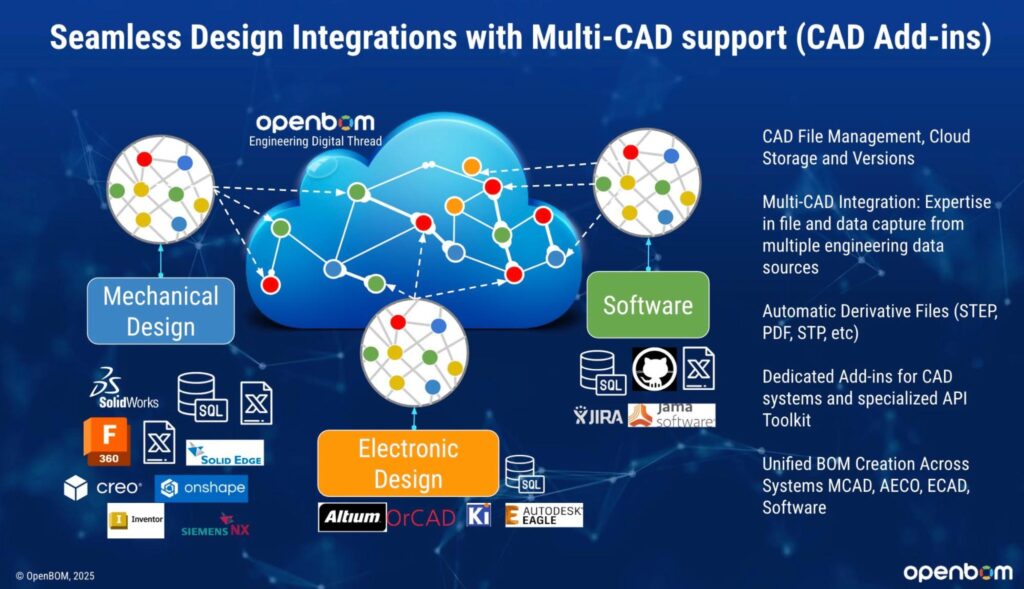

OpenBOM Connectors – Bringing CAD Data into the Workspace

The first step to fixing this problem is breaking CAD data out of its silo.

OpenBOM offers native CAD connectors for all leading tools—SolidWorks, Autodesk Fusion, Onshape, Altium, and others. These connectors allow engineers to publish live BOMs directly from CAD into OpenBOM with just a few clicks.

Instead of relying on a standard file exports or manually updated spreadsheets, teams now have a real-time connection between their CAD models and a shared cloud workspace.

For example, when an engineer adds a new component or updates a part number in the CAD assembly, OpenBOM automatically reflects that change in the BOM. Procurement sees it immediately—no waiting for the next release cycle, no chasing engineers for clarification.

This live connection eliminates the most common source of miscommunication: outdated or incomplete design data reaching procurement.

Real-Time BOM Creation – Live Links to Catalog and Part Numbers

A second breakthrough comes from how OpenBOM organizes data.

Every BOM created in OpenBOM is tied to a centralized item database for an entire organization. This catalog stores part numbers, descriptions, sourcing information, cost, supplier details, and even lead times.

When an engineer publishes a BOM from CAD, OpenBOM links every line item in that BOM to the catalog. That means the purchasing team isn’t just seeing a list of CAD parts—they’re seeing all the business-critical attributes they need to buy those parts.

The result is a living, dynamic BOM that stays up to date across engineering and operations. If a vendor changes a part’s lead time or price, procurement can update the catalog entry and that update propagates automatically to every BOM using that part.

This approach saves hours of repetitive work and eliminates the risk of procurement acting on outdated part information. Everyone sees the same data, updated in real-time.

Procurement Planning and Ordering – From BOM to Purchase

Unlike traditional PDM or PLM tools that stop at design and engineering, OpenBOM also provides inventory and procurement planning tools. It is extremely important for small companies and agile development teams.

This means once a BOM is published, purchasing teams can:

- Roll up quantities across multiple BOMs or configurations.

- Check current inventory to avoid over-ordering

- Assign suppliers and compare vendor pricing.

- Generate purchase orders directly within OpenBOM.

This integrated workflow dramatically reduces the back-and-forth between users and departments. Procurement no longer has to request updated spreadsheets or hunt down part details from engineering. Instead, they can plan, source, and order using the same collaborative workspace engineers use to design the product.

FenceQuip saw significant benefits from this approach. By centralizing data and removing redundant manual processes, they were able to streamline purchasing, reduce waste, and free up working capital—key improvements that supported their lean manufacturing goals.

ERP Integration – Working with Existing Systems

For those manufacturers that have grown up to ERP to manage purchasing, inventory management, and financials, OpenBOM provides a seamless integration.

ERP systems often struggle to receive accurate engineering data because they were never designed to integrate seamlessly with CAD tools.OpenBOM solves this by acting as the bridge between engineering and ERP.

Accurate product structures and BOMs created in OpenBOM can be automatically fed into ERP for downstream processes like procurement approvals, scheduling, and costing.

OpenBOM provides out-of-the-box integrations with popular ERP platforms and offers custom integration services for companies with unique requirements. This flexibility ensures that businesses can connect engineering to procurement without replacing their ERP investment.

End-to-End Traceability – A Single Source of Truth

When CAD, BOM, and procurement planning all flow through one workspace, something powerful happens: end-to-end traceability.

Every step of the process—from a part’s initial design in CAD to the moment it’s purchased—can be tracked in OpenBOM’s collaborative workspace.

If a production issue arises, teams can quickly trace it back to a specific revision, BOM change, or supplier decision. Managers gain full visibility into who changed what, when, and why, which is invaluable for audits, compliance, and quality assurance.

This transparency reduces costly errors, accelerates quoting, and strengthens trust between engineering and procurement.

Customer Spotlight – FenceQuip

FenceQuip’s journey illustrates the transformative power of bridging engineering and procurement. Before adopting OpenBOM, their teams operated in silos, relying on CAD exports, spreadsheets, and email to coordinate. Miscommunication led to over-ordering materials that tied up capital and under-ordering critical components that delayed production.

Read the story of FENCEQUIP to learn how OpenBOM helped to connect their CAD data directly to procurement, introduced a single source of truth for BOMs, and implemented lean purchasing practices. The result was a significant reduction in waste, faster turnaround times, and more efficient use of cash—proving that the right digital thread pays off on both the shop floor and the balance sheet.

Conclusion: Bridging the Gap

The biggest productivity gain in manufacturing often comes from solving what seems like a simple problem: connecting engineering to procurement.

Too often, teams focus on refining CAD models, struggling with spreadsheets based procurement or manual entry data to ERP while the most critical digital thread—the one that connects the two—remains broken.

OpenBOM was created to open engineering data to the business. By bridging CAD, BOM, inventory, and purchasing in a single collaborative workspace, OpenBOM empowers companies to streamline operations and reduce costly errors.

Whether you’re still working out of spreadsheets or already running a sophisticated ERP, OpenBOM helps you close the loop on the design-to-order digital thread.

In the next blog (Day #6) of this series, we’ll explore how OpenBOM’s real-time collaboration features bring engineers, buyers, and suppliers together to work on the same data without barriers.

REGISTER FOR FREE to check how OpenBOM can help.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.