If you walk into a typical manufacturing company of 50 or 200 people, you’re likely to find a scene that hasn’t changed in decades: CAD models on shared drives, Excel spreadsheets tracking part lists, finance and ERP systems running somewhere in the background for purchasing and accounting.

For companies building complex products—machines, robotics, electronics—this patchwork often works just well enough to keep things moving. But it’s fragile. The moment designs change, new configurations are added, or orders need to be placed quickly, the cracks start to show.

That’s why the Bill of Materials (BOM)—and the product data that surrounds it—still sits at the very heart of manufacturing.

And that’s why Day 2 of our 30-day OpenBOM journey focuses on how to move from CAD documents and spreadsheet chaos to a digital BOM that connects product data, people and processes in real time.

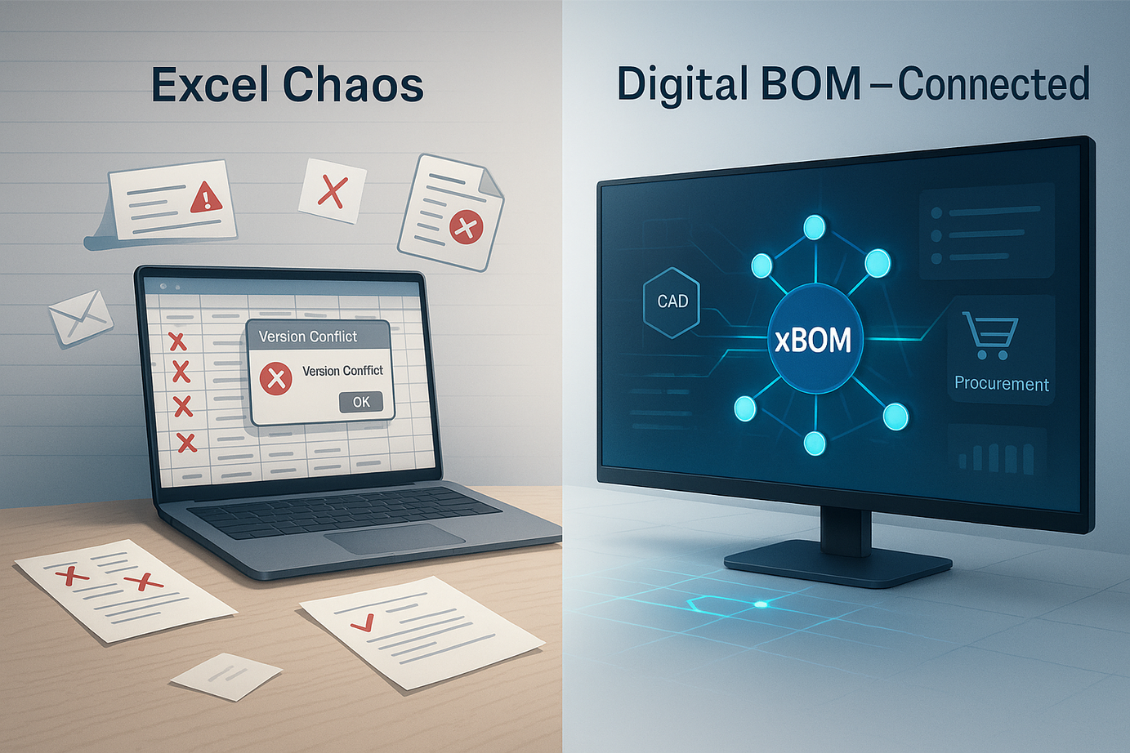

The Reality: CAD in Files, BOMs in Excel, Process in Emails

Most small and mid-sized manufacturers begin with BOM in spreadsheets because they’re familiar, flexible, and inexpensive. But as soon as multiple engineers, buyers, and production planners start editing them, problems surface:

- CAD files stored in the disc (or cloud drive)

- Different versions of the same file, duplications, spreadsheets circulate in email.

- Someone forgets to update a revision after a late-night CAD change.

- Quantities get out of sync with purchasing orders.

- By the time a supplier receives the file, it’s already outdated.

Everyone recognizes the pain, yet it persists because Excel feels simple and the current status quo — until it isn’t.

BOM ≠ Just a Table

Although, it is argued by many old school engineers, a BOM is far more than a static list of part numbers. It’s a living structure that links design files and intent to every business activity outside of engineering — manufacturing instructions, cost and sourcing data, regulatory and quality documentation, even service records once the product is in the field.

When that structure is trapped in spreadsheets and CAD files are in folders, you lose the “living” quality. Each engineer or department sees only its own copy. Changes become invisible across the chain, and no one has a reliable source of truth.

The Cost of Chaos

This is something many engineers and companies are missing. There is cost for the status quo. Disconnected CAD files and BOMs have a measurable cost:

- Rework and scrap: a single missed revision can send the wrong part to the shop floor.

- Wrong orders and delays: purchasing often discovers changes too late, leading to express shipping or schedule slips.

- Supplier friction: partners receive inconsistent data and must confirm details repeatedly.

- Traceability gaps: when quality or compliance issues arise, finding the right version of the BOM can take days.

We have a customer who said OpenBOM found a mistake in a BOM, which covered the cost of OpenBOM’s annual subscription. I’ve seen teams spend an entire week organizing Excels for a shipment and it turned into a nightmare because a spreadsheet column hadn’t been updated after a design tweak – time, money, and morale all lost to preventable data errors.

The Case for a Digital BOM (Connected Product Data + AI)

The alternative is a digital BOM—one that lives in the cloud, connects all related product data, and is ready for AI.

In a digital BOM environment, design changes flow automatically from CAD into the BOM; CAD data and derivative files are generated and linked in real time, purchasing sees updates immediately, and manufacturing gets accurate roll-ups for quantities and costs without exporting or merging files. Every stakeholder works from the same live structure, with a clear history of revisions and approvals.

With OpenBOM’s graph-based “product memory,” powered by the OpenBOM graph based model, using MCP Server and AI Agents, the digital BOM turns into actionable knowledge.

This product memory links parts, revisions, suppliers, and CAD data, enabling AI to validate BOMs, spot inconsistencies, flag missing attributes, recommend alternates or substitutes, and guide cost trade-off decisions—all inside the same live digital thread.

The result is less time spent “syncing spreadsheets” and more time building products, plus smarter decision-making powered by AI. It’s also about accountability and traceability—knowing who changed what, when, and why, across the entire lifecycle.

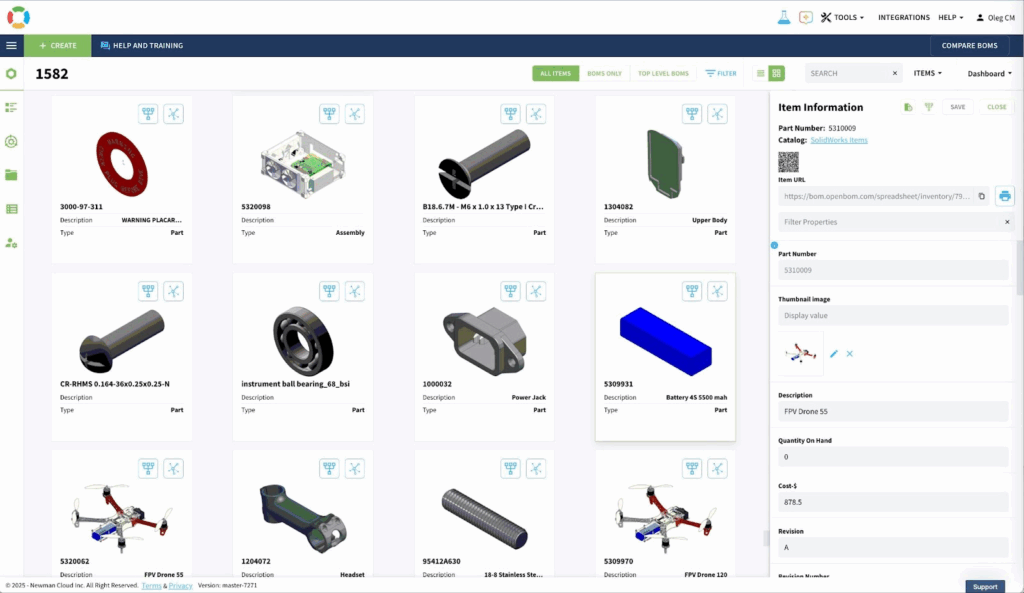

How OpenBOM Delivers It

OpenBOM was created to make this transition practical for manufacturers of complex products who are still living in CAD + Excel + Email workflows.

- Its cloud-based catalogs and items create a single source of truth for all components and assemblies.

- The reference-instance model eliminates duplicate data while still letting teams represent variations and configurations accurately

- Live CAD links through add-ins for Fusion, SolidWorks, Onshape, Altium and others ensure BOMs stay in sync as designs evolve.

- The collaborative interface feels as simple as a spreadsheet but lets engineers, buyers, and even suppliers work together in real time without sending files back and forth.

Shifting from spreadsheets to a connected, cloud-based BOM is often the first big productivity win for our customers’ experience—laying the foundation for more advanced capabilities like cost roll-ups, procurement planning, and AI-assisted decision support later in the journey.

Conclusion:

Even with today’s advanced tools, the BOM, including all product data, remains the backbone of manufacturing data. When it’s fragmented across spreadsheets, file storages and emails, that backbone becomes brittle.

Moving to a digital, connected BOM restores its strength—tying together design, purchasing, and production so that everyone works from the same reliable product data.

Tomorrow, in Day 3 of this series, we’ll look deeper under the hood at OpenBOM’s architecture—how a multi-tenant, graph-based model makes this level of collaboration possible.

Meantime, REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.