Data is a centerpiece of every business software. Well defined information sets can help to organize and orchestrate processes. For engineering and manufacturing, the Bill of Materials (BOM) is the core mechanism that connects engineering, procurement, and operations. Whether you’re generating purchase orders, forecasting inventory, or planning production, everything starts with an accurate and connected BOM.

ERP Integrations were one of the key elements, together with CAD integrations, allowing OpenBOM to be seamlessly connected with different data sources. Check my earlier article – OpenBOM ERP Integrations: Best Practices and Tools. Two years later, it is time to refresh and expand what we do.

From my experience, integrating BOMs with ERP systems remains one of the most critical and challenging steps for manufacturers. Disconnected tools, point-to-point integrations, and one-time exports have long slowed down business processes. At OpenBOM, we believe the future demands more: automated synchronization, context-aware data flows, and intelligent workflows that keep every team aligned.

That’s why OpenBOM’s ERP integrations in 2025 go far beyond basic connections — they are built on a foundation of flexibility, openness, and intelligence.

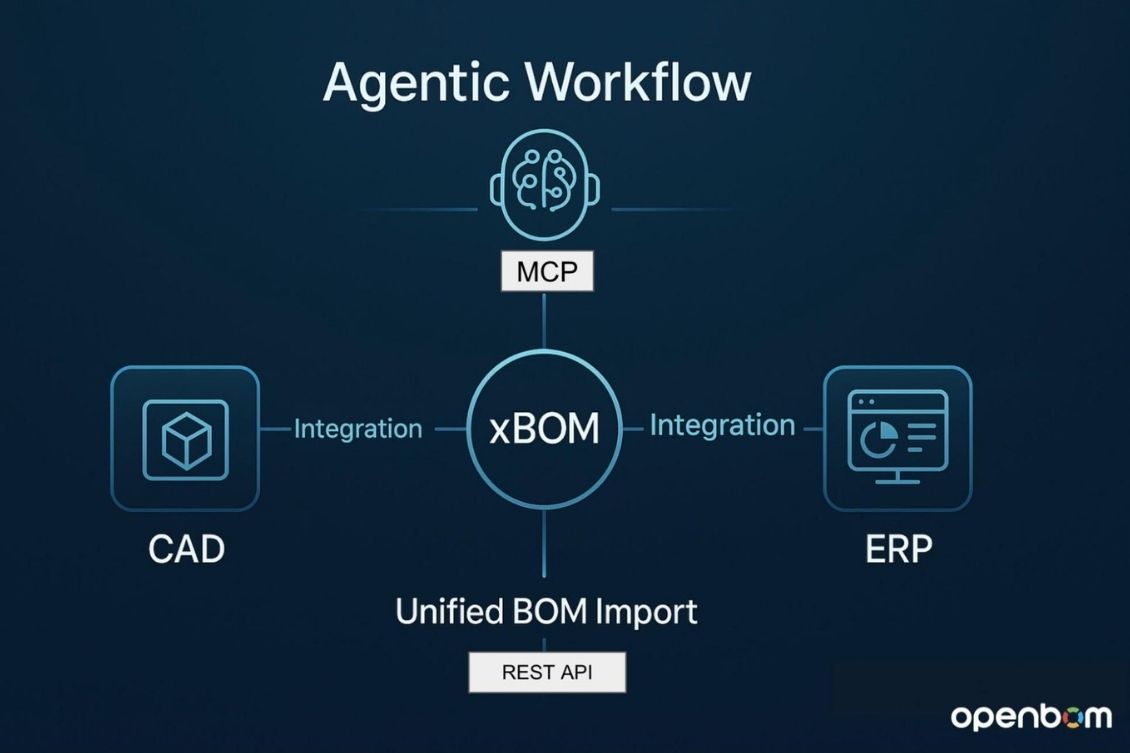

A New Foundation: xBOM and Data Orchestration

The key to modern ERP integration is OpenBOM’s xBOM service – a multi-view, graph-based BOM architecture that enables companies to model, manage, and share product structures across the entire lifecycle.

xBOM allows you to create tailored views of your BOM for engineering, manufacturing, sourcing, service, or compliance. This semantic and contextual flexibility is what makes synchronization with ERP systems efficient and scalable. Instead of trying to “flatten” product data into rigid formats, OpenBOM adapts to the needs of each connected system.

More importantly, xBOM provides the foundation for orchestrating data transfers — synchronizing items, quantities, suppliers, and cost data across multiple endpoints while maintaining context, relationships, and traceability.

More ERP Integrations Added

In 2025, OpenBOM continues to expand its integration portfolio with ready-to-use connectors for popular ERP systems:

- NetSuite (significantly expanded)

- QuickBooks (expanded with advanced data mapping and additional features)

- Odoo (flexible and configurable)

- Visma Business NXT ERP (custom-built based on the requirements)

- More integrations are coming, including internationally and regionally popular ERPs

These integrations allow you to push BOMs directly into your ERP system, update item masters, and generate purchasing information — all with minimal manual intervention.

But the real strength lies in flexibility. If your system isn’t yet natively supported, OpenBOM’s API Integration Toolkit lets you build custom synchronization processes tailored to your specific business logic, data model, and update cadence.

Seamless Import and Synchronization

Before sending data and synchronization with ERP, there is a need to clean, transform, or organize data, which often becomes a manual and error-prone bottleneck.

To make it super easy, OpenBOM is introducing the Unified BOM Import – an improved feature that allows users to drag-and-drop BOM spreadsheets, automatically detecting:

- Excel format, Part Numbers

- Quantities and structure

- Subassemblies and levels

- Vendor and manufacturer information

This streamlines data import, which is combined with CAD integrations, allowing you to bring data to BOM from multiple sources and then make it ready for ERP synchronization or sourcing tasks without rework.

Agentic Workflows: The Next Frontier

But we’re not stopping at data synchronization. We’re building toward a future of agentic workflows, which are intelligent, autonomous agents that operate within OpenBOM to perform tasks, data transformations, and synchronizations.

Powered by BOM AI (announced in our recent press release), OpenBOM will soon support agents capable of:

- Validating and correcting BOM data before ERP sync

- Monitoring for changes and triggering automated updates

- Suggesting alternate or substitute parts based on real-time supplier data

- Calculating costs and updating ERP values dynamically

- Coordinating data transfers between multiple systems, workflows, and users

This agentic infrastructure allows companies to move from manual workflows to intelligent automation — freeing up engineering and operations teams to focus on high-value work.

Open Standards: From REST API to MCP

OpenBOM’s open architecture is designed to fit into modern enterprise ecosystems. Together with REST API, we are currently expanding support for agentic workflows using MCP (Model Context Protocol).

An addition to MCP (Model Context Protocol) brings a set of new opportunities to integrations using AI agents.

This means you can integrate OpenBOM not only with ERPs, but also with other enterprise data management systems, MES, PLM, and custom-built tools — making OpenBOM a central part of your digital thread.

All together, these open standards enable model-based, context-aware communication with systems that require rich product data semantics

Conclusion

The engineering and manufacturing world is becoming extremely intertwined and connected. The demand to use multiple systems and connect online services is everywhere. CAD-BOM-ERP integration is no longer “nice to have.” It’s a critical requirement for every product-centric company. But simple exports and rigid tools are no longer enough. Companies need real-time, flexible, intelligent integration, and that’s exactly what OpenBOM delivers.

From xBOM modeling and seamless BOM import to a growing library of ERP integrations, agentic automation, and powerful APIs, OpenBOM gives manufacturers the tools they need to stay connected, responsive, and ready for the future.

Ready to connect OpenBOM to your ERP?

REGISTER FOR FREE and contact our support to explore more about OpenBOM’s integration options.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.