This article is the next chapter in the OpenBOM Data Model 2025 Update series. If you’re new to the series, I recommend starting with the earlier posts:

- OpenBOM Data Model 2025 Update: A High-Level Overview

- OpenBOM Core Data Model – Objects, Properties, Links

- Reference–Instance Product Structure and xBOM: A Modern Data Architecture for Product Models

With those fundamentals in mind, let’s move into the next chapter: Design Projects.

Introduction: Bridging Structured Data and Design Files

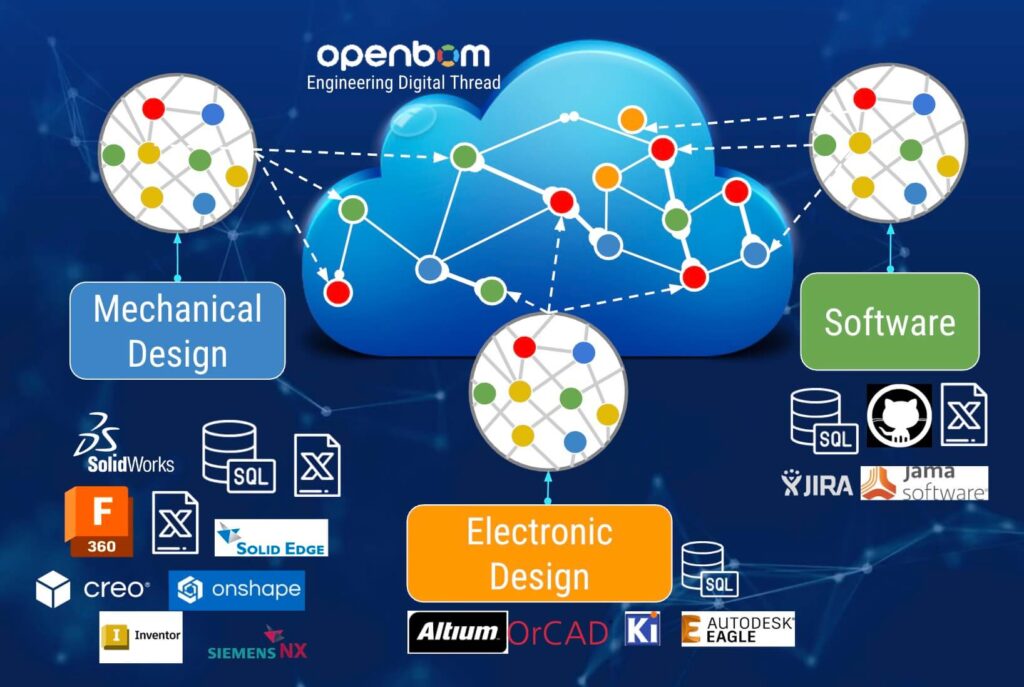

In the previous chapters of this series, we explored how OpenBOM’s data model provides a flexible, graph-based approach to managing product information. We talked about objects, properties, and views as the foundation, and then examined how product structures are modeled using the reference–instance principle. That foundation is critical because it ensures product data is structured, consistent, and traceable.

But let’s be honest: modern engineering isn’t just about BOMs and item properties. Files are still everywhere. CAD assemblies, part models, drawings, specifications, PDFs, spreadsheets—the unstructured side of product data is alive and well. While BOMs capture structure and metadata, design files capture geometry, intent, and detail. Ignoring them isn’t an option.

This is where OpenBOM Design Projects come into play. They extend the OpenBOM data model to handle file-based design data—bringing PDM-like capabilities into the same unified platform.

Design Projects as a PDM Service

If you’ve ever struggled with file vaults, rigid check-in/check-out workflows, or disconnected PDM systems, you’ll understand why OpenBOM took a different path. Design Projects is not “just another PDM” tool—it’s a cloud-native service that leverages OpenBOM’s core data model.

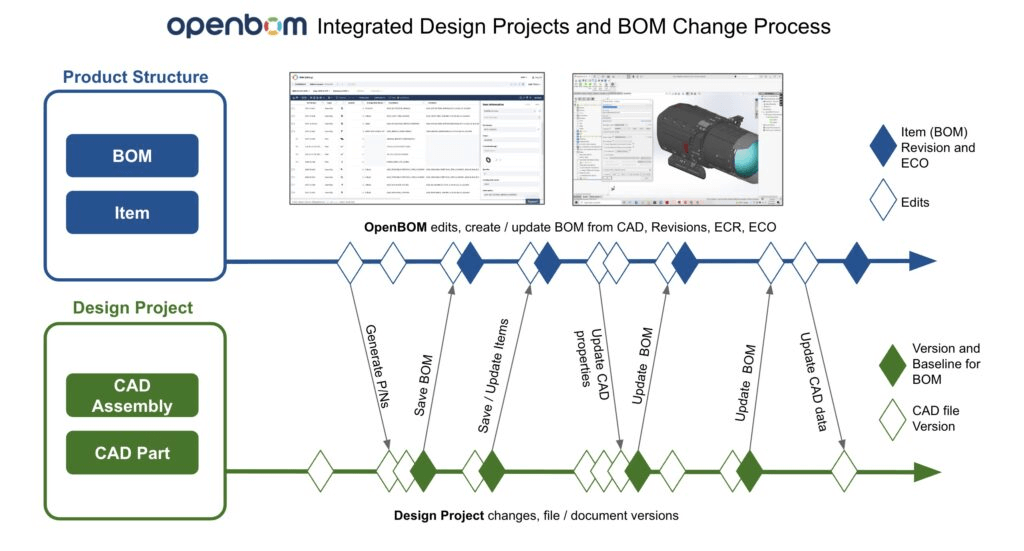

Think of it as a PDM layer built on the same object–property–link foundation we’ve been exploring. This means files are not treated as isolated blobs in a vault. Instead, they are modeled, versioned, and connected to items, BOMs, and the broader digital thread.

With Design Projects, OpenBOM:

- Manages CAD and any other file type.

- Provides version control and traceability.

- Links design data directly to structured product data.

- Enables real-time, collaborative workflows across distributed teams

This approach eliminates the historical PDM/PLM divide. Instead of having one system for CAD files (PDM) and another for product structures (PLM), OpenBOM unifies both under one connected model. At the same time, OpenBOM data model provides full support for separate management of design data (Design BOM / DBOM) and engineering product structure (EBOM).

Core Capabilities of Design Projects

Let’s break down what Design Projects actually do.

CAD File Management

You can upload, organize, and manage CAD files directly in OpenBOM. Files are not siloed in separate vaults; they’re part of the same ecosystem that manages your BOMs, items, and catalogs.

Version Control

Every file has a version history. Designers can create new versions, track revisions, and always know which file is linked to which product release. This ensures clarity across engineering and downstream functions.

Linking to Items and BOMs

Perhaps the most important capability: files are connected to items and BOMs. A CAD part isn’t floating in space—it is linked to its catalog entry, which in turn is part of assemblies, which roll up into manufacturing BOMs. That’s the digital thread in action.

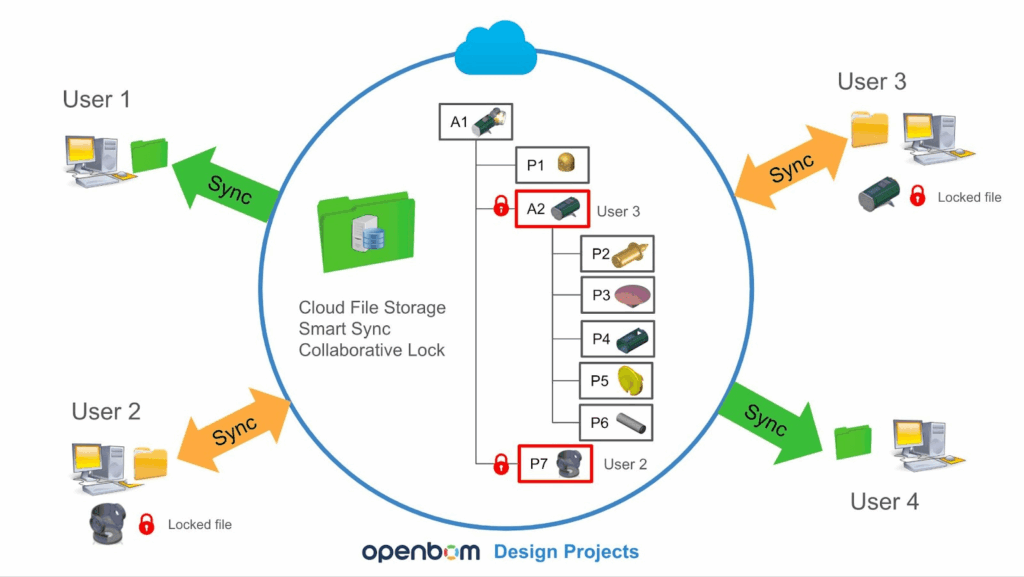

Collaborative Lock

One of the standout innovations is the collaborative lock mechanism. Traditional PDM systems rely on strict check-in/check-out. It’s effective, but often too rigid for distributed teams. OpenBOM rethinks this. The collaborative lock allows multiple users to work in context while still ensuring data integrity. It’s the next generation of file control—modern, cloud-native, and designed for global collaboration.

Design Projects Data Model Deep Dive

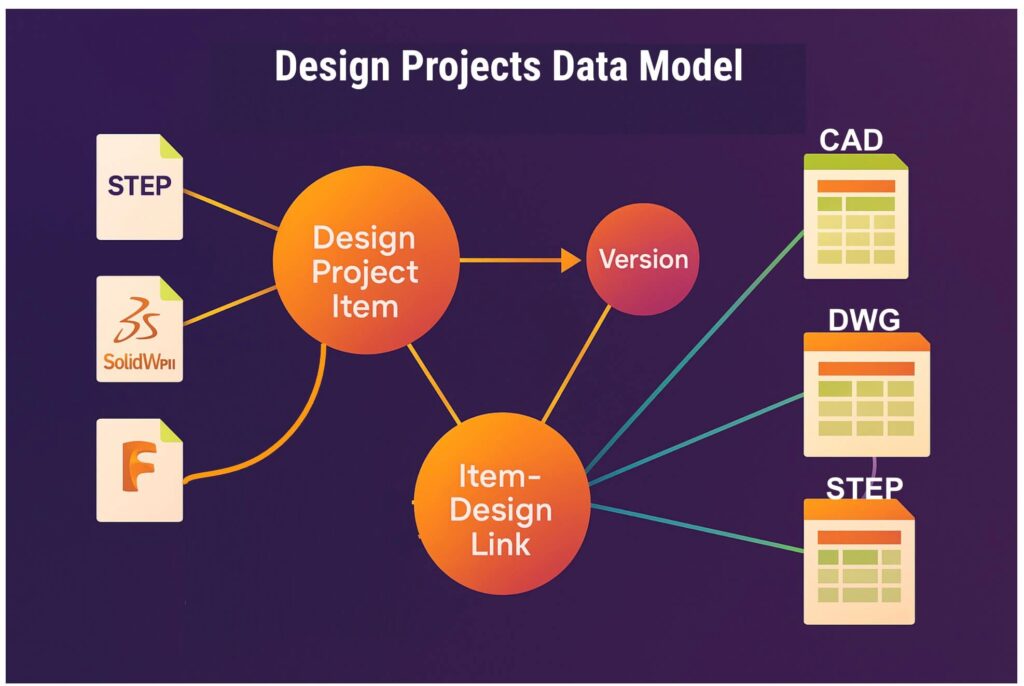

Let’s take a closer look at the data model underpinning Design Projects. Just like with product structures, the design project model relies on objects and links.

- Design Project Items

Each design project item is an object in the OpenBOM model. It is associated with file storage and metadata. This means the file isn’t “just a file”—it has properties, attributes, and a lifecycle. - Version Objects

Versions are first-class citizens. Every time a new version is created, it’s stored as a separate object, preserving lineage. This makes it easy to roll back, audit, or compare across versions. - Item–Design Links

The most powerful element is the link between items (catalog entries) and design project items (CAD files). This ensures that every part number, every catalog entry, every BOM line can be tied directly to its design representation.

This structure fits naturally into OpenBOM’s graph-based architecture. Instead of a rigid vault, you have a flexible, networked model where relationships can be navigated visually and programmatically.

Integration with CAD Systems

Of course, none of this matters if it doesn’t work with the CAD systems engineers use every day. That’s why OpenBOM has built integrations with leading CAD tools—from SolidWorks and Autodesk Fusion to Onshape, Inventor, and beyond.

These integrations mean:

- Files can be captured automatically during design work.

- Metadata flows seamlessly from CAD into OpenBOM’s structured data model.

- Links between CAD files and BOMs are maintained automatically.

- Access to a file is blocked using a collaborative lock (a modern form of “check-out”) to prevent changes to CAD files that are already locked by another user.

Instead of manual uploads or disconnected exports, the integrations ensure design work stays in sync with the product lifecycle.

6. Eliminating the PDM/PLM Divide

For decades, companies have been stuck with a two-system problem:

- PDM for CAD files and design data.

- PLM for product structures, BOMs, and lifecycle management.

This split creates silos. Engineers live in PDM. Operations live in PLM. And too often, these systems don’t talk to each other.

OpenBOM Design Projects eliminate this artificial divide. By embedding file management inside the same data model as BOMs and items, OpenBOM provides:

- A single source of truth for both structured and unstructured data.

- Simplified workflows that don’t require switching between systems.

- A digital thread that connects design intent all the way to manufacturing and the supply chain.

This is not just a technical improvement—it’s a cultural one. It aligns engineering, operations, and manufacturing around the same data model.

7. Practical User Benefits

What does this mean for real users?

- Engineers get lightweight, modern file management without the overhead of legacy PDM systems. They can focus on design, not fighting with a vault.

- Teams gain transparency. Everyone can see the latest versions, track changes, and collaborate without conflicts.

- Companies align design intent with downstream processes. Manufacturing teams don’t have to wonder which drawing is correct. Procurement doesn’t have to guess which CAD revision matches the BOM.

The result: faster collaboration, fewer errors, and stronger confidence in the product data.

Conclusion: A Unified Data Model for Design and Engineering Digital Thread

With Design Projects, OpenBOM extends its data model beyond structured BOMs and items into the world of design files. By treating CAD data as objects with versions and links, OpenBOM delivers PDM capabilities without the complexity of traditional PDM systems.

The key differentiators are:

- A graph-based data model that naturally connects files, items, and BOMs.

- Collaborative lock for modern, distributed teamwork.

- Seamless CAD integrations to ensure data flows where it’s needed.

This unification of file-based and structured data is what sets OpenBOM apart. It’s not PDM versus PLM—it’s one model that covers the entire digital thread.

Stay tuned for the next chapter in this series, where we’ll continue to explore the OpenBOM Data Model and its role in building the future of digital product lifecycle management.

REGISTER FOR FREE to check OpenBOM Design and how it can help your teams.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.