Serialization is a process that allows creating a BOM with a specific (serial) part number once the product is manufactured and delivered to the customer. The serialization process can be quite complex and involves rules of how many levels (or what levels) in the product structure will be serialized. In a simple use case, only the top level of the BOM will be serialized and all other levels will stay the same. In some situations, companies can decide to serialize specific units. The most common use case is to organize a BOM in a modular fashion and to serialize a certain number of levels moving top down.

Serial Numbers and BOM Serialization

Earlier this year, I wrote a few articles that would help you understand how to manage the serialization process using OpenBOM. The robustness of the OpenBOM data model allows you to serialize each specific Bill of Materials (using a “copy BOM” command) and create a full record of serialized BOMs. Multi-tenancy and instant data sharing of OpenBOM will allow you to share each serialized BOM with the customer and to maintain the record of each product in the field.

Check these articles for more information.

Managing BOMs with serial numbers

How to Manage serial numbers and as-built BOMs

Production Batches and Manufacturing Lots

Batch production is a method when a group of identical products will be manufactured simultaneously. A manufacturer can device how big is the batch and how often they will be made. Each production batch goes through the separate stages of the manufacturing process at the same time. It means that until the batch is finished the production process won’t stop and all products will have the same characteristics (and will have the same BOM), their specification won’t change.

In this case, you built a series of products (eg. industrial equipment or electronic device), which are grouped together and, technically, will have the same items that will never change from the product standpoint during their lifecycle with the customer. This group of products will be called a lot (or a batch) and will be identified by a specific lot number (Serial lot) that will be used for the identification of the product.

Order BOMs and Lot Serialization

The importance of the lot number is high, especially when it comes to the problem of traceability and regulation. Manufacturing would like to know exactly what data (specification) was used for each batch – parts, their revisions, files, etc. To manage this information is extremely important, but to make it happen is not that easy. The main aspect of the complexity is to keep the structures in sync and assign specific characteristics to a set of items.

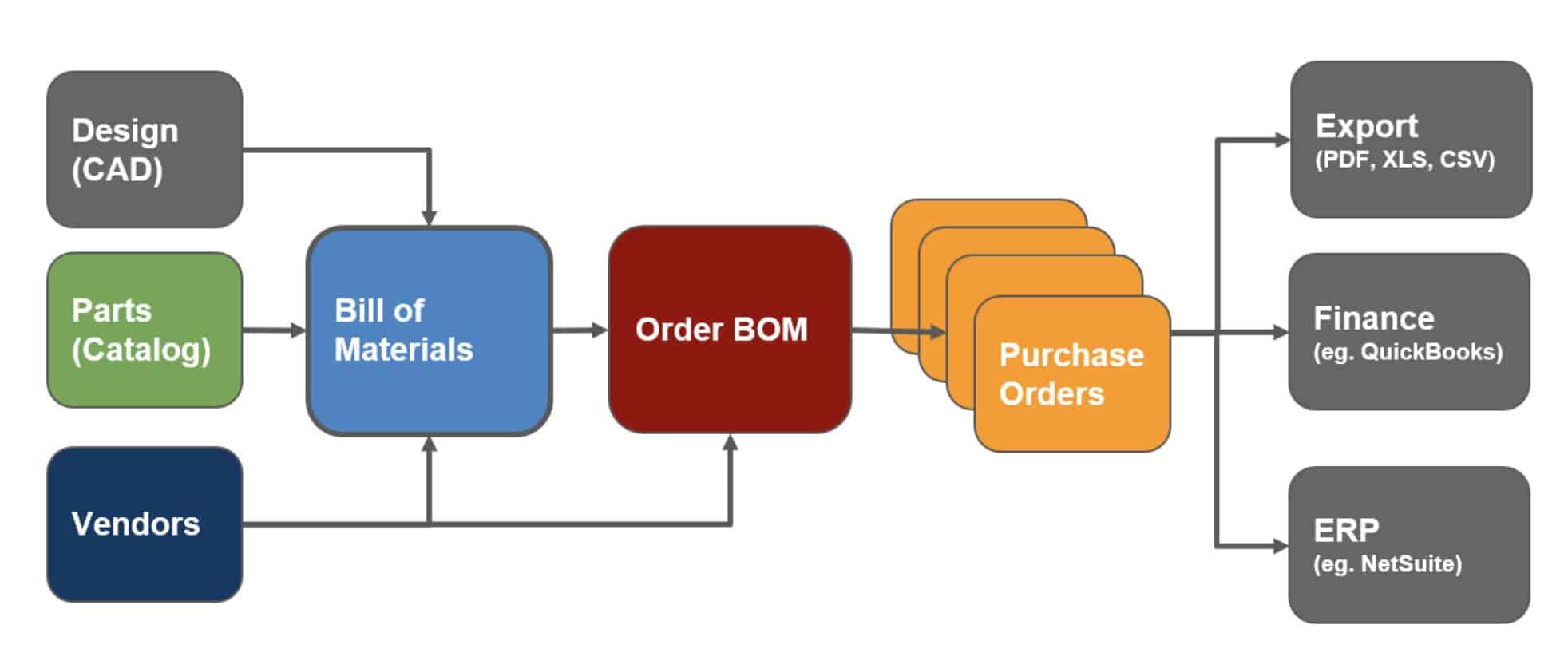

OpenBOM production planning and release process make production batches and lot serialization very easy by managing Order BOM. A process diagram below shows the business logic organized in OpenBOM – moving from design to production by creating item databases (catalogs), bill of materials, and later order BOMs.

What makes Order BOM an ideal way to manage serialization for lots is that each order BOM is actually a production batch with a specific number and quantity size (batch size). It creates an isolated copy of all items that are used to produce the batch with all information coming from BOMs and catalogs flattened with the total number of part and assembly quantities.

Additional data (properties) can be added to order BOM to store more business information about the specific batch, specifications used for production, validations, regulations, and many other references. Combined together, all this data creates a foundation for historical traceability and connection between order BOM and item/BOM database used to create it.

Once you are ready to manufacture, the Order BOM can be released to production and stay immutable forever. So, you can always relate to previous order BOMs as a full history of production batches made by a company or shop.

Conclusion

Modern manufacturing creates a lot of challenges and demands the traceability of the products after they have already been manufactured. Therefore manufacturing companies are looking for robust data management systems to allow them to manage not only engineering data but also a full product lifecycle including production stages and serialization processes. While sophisticated ERP systems are out of reach for many small and medium enterprises, the need to serialize the production data is the same. OpenBOM Order BOM functionality is a way to manage batch traceability and to serialize the information about production batches.

Want to check out how OpenBOM can help you? Register for free and start a 14-day OpenBOM trail to explore all of OpenBOM’s functionality.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.