Engineers rarely build entirely new products from scratch. Whether designing machinery, electronics, or high-tech projects, most products are evolutions of existing designs with modifications to meet new requirements or new customer orders. Even a completely new product, will re-use some elements of the original assemblies and components.

Here is the challenge: Managing “Derivative” Design Projects

Imagine you’re an engineer tasked with developing a new product variant based on an existing design. You immediately face practical questions:

- How do you organize the design data without overwriting existing files?

How do you track versions and revisions of the new design separately? - How do you create a new BOM and production plan derived from the old one but with updated components, part numbers, and attachments?

Traditional CAD file management systems can struggle here. Copy file, rename, ensure unique file names to put them under control, etc. They either prevent duplicate file names or lack structured ways to create derivative projects efficiently.

OpenBOM’s Approach: Flexible Project Copying and Digital Production Planning

OpenBOM’s approach relies on separate management of CAD files and their versions and production of a digital BOM with derivatives.

Here are more details about how you can do it using OpenBOM:

Seamless Design Project Management with Duplicate File Names

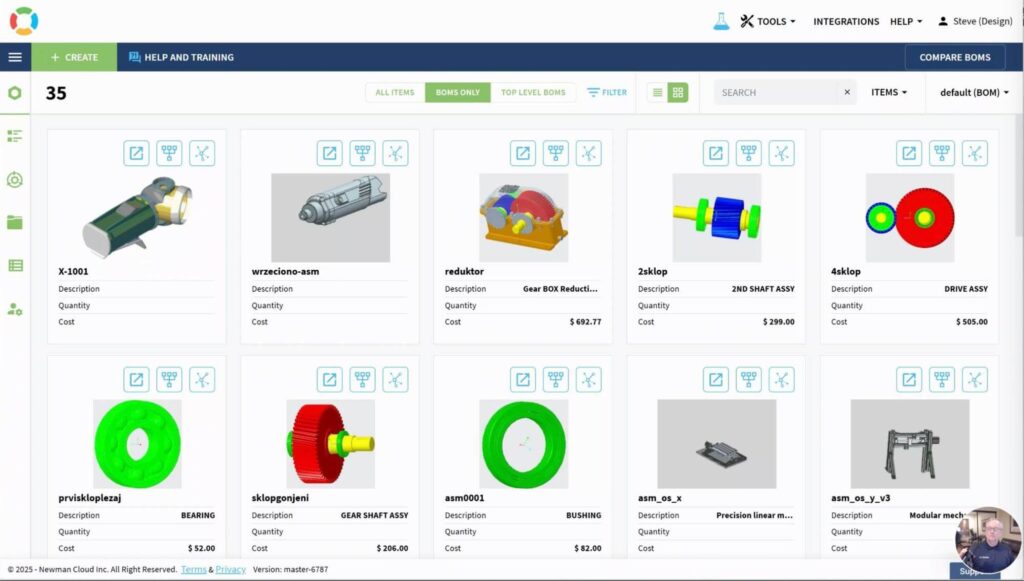

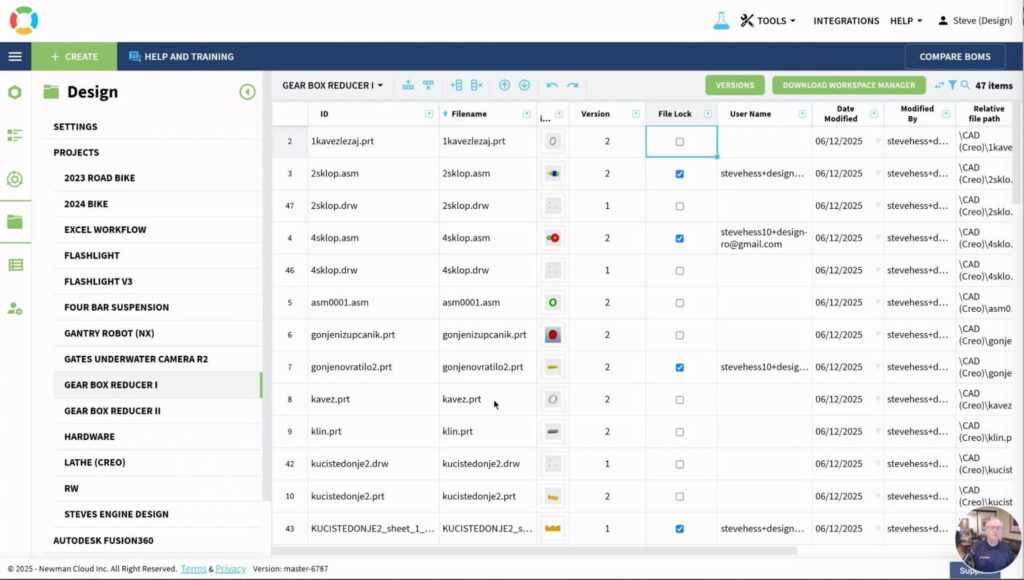

OpenBOM allows you to manage CAD design files using Design Projects – seamlessly stored in the cloud, fully versioned, and organized per project. Unlike many traditional systems, OpenBOM’s flexible data model allows duplicate file names across projects because each project context is isolated yet connected within the overall data model.

✅ What does it mean for you?

You can create a copy of an existing project without worrying about renaming every file. Your new project inherits the structure, and you can modify as needed.

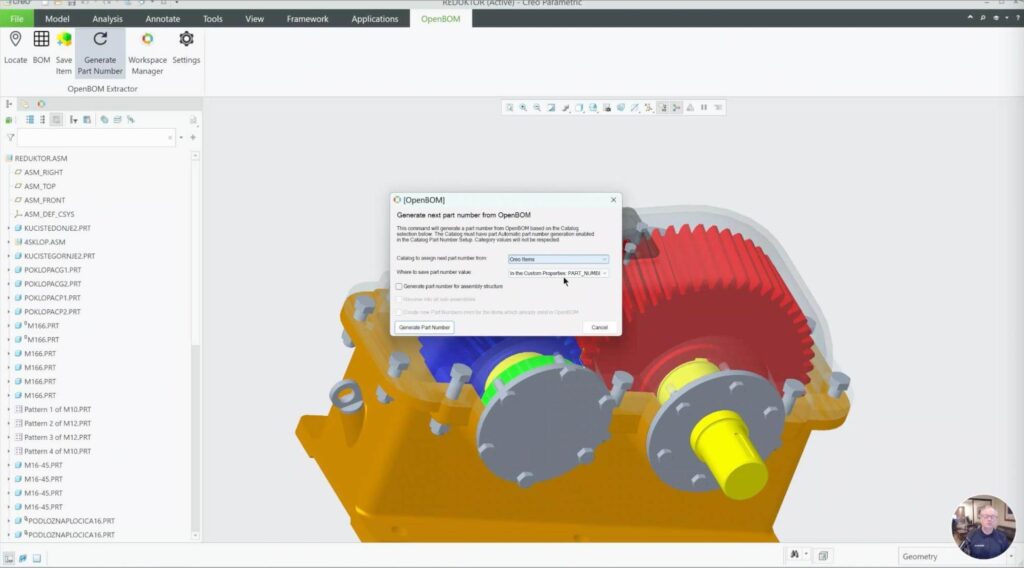

Generating New Part Numbers for Design Copies

After you produce a copy of an existing project and sync it in the cloud, OpenBOM can regenerate new Part Numbers to uniquely identify all components, assemblies, and sub-assemblies within the new design. You can apply this regeneration partially or fully, depending on the use case.

✅ Why is this important?

You avoid part number conflicts and maintain clear traceability between original and derived designs, ensuring procurement, manufacturing, and engineering teams stay aligned.

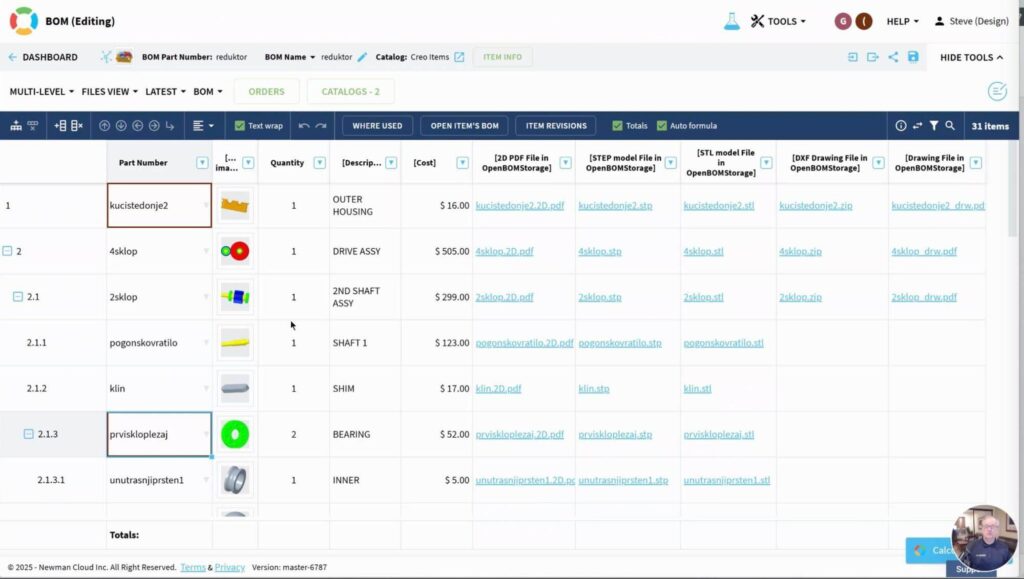

One-Click Digital BOM Creation with Attachments

OpenBOM’s one-click BOM creation produces a comprehensive digital BOM, including all attachments – CAD files, derivative files, and supporting documentation. This transforms design data into an actionable product structure seamlessly.

✅ Outcome:

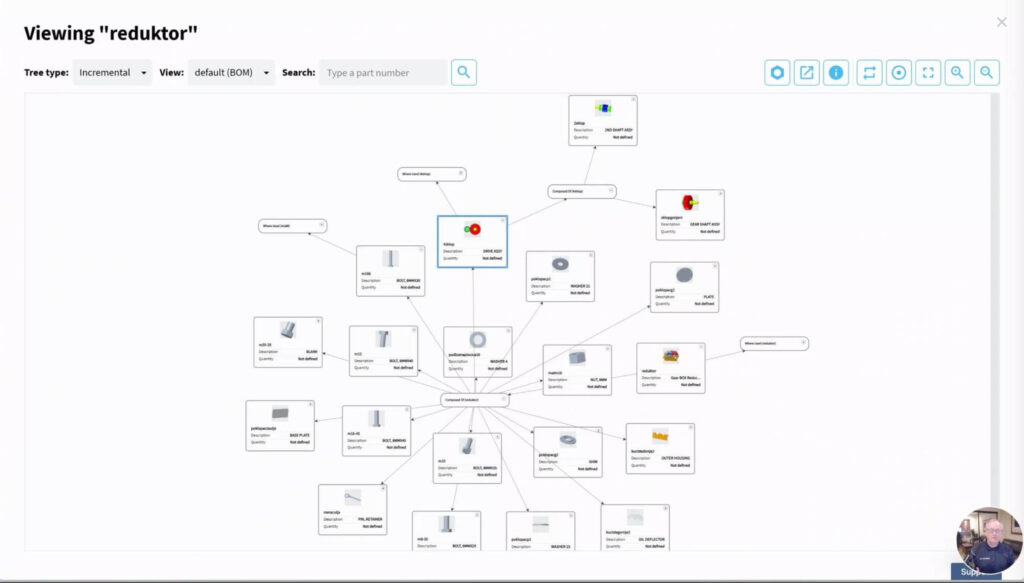

Your design is instantly production-ready, with all data organized and accessible for downstream processes. Bonus: A very nice visualization done by OpenBOM Graph Navigator

Revision Control and Production Planning

OpenBOM provides full revision control, allowing you to release the digital product structure and create production plans based on released designs.

✅ Result:

You can confidently move from engineering to manufacturing, knowing your released BOM is controlled and versioned for traceability and compliance.

Quantity Gap Reports and Procurement Integration

Once the BOM is finalized, OpenBOM generates Quantity Gap Reports by comparing required quantities to inventory levels. You can then automatically generate purchase orders (POs) to send to contractors and suppliers, ensuring timely procurement for production.

✅ Benefit:

Procurement planning is streamlined, reducing delays and manual errors.

Video Demonstration

📹 Watch the video to see how OpenBOM manages CAD files in design projects (e.g. Creo) and generates digital BOMs with all attachments.

Conclusion: Efficient Design Copying for Engineering-to-Order Or New Product Development

OpenBOM provides a flexible foundation for design project management, efficient design copying, and production planning. It is especially useful for:

- Companies developing new custom projects

- Engineering-to-order manufacturers

- Organizations building complex configurable products derived from standard base models with customer-specific modifications

In a modern manufacturing environment, being able to reuse and adapt is as critical as creating new. The need for speed is here. OpenBOM makes this process seamless, organized, and production-ready.

Ready to manage your derivative design projects efficiently?

REGISTER FOR FREE and get an instant trial.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.