I’m continuing to give you a preview of new functions coming very soon to OpenBOM. We’ve been working on few very substantial improvements in OpenBOM features and functionality related to inventory management and purchasing. Original functionality was mainly focused on providing batch planning and purchasing estimation. During the last year, we received many requests from our customers to improve functionality related to inventory management and the ordering process. Today, I will give you a bigger picture of what will be improved in the coming release.

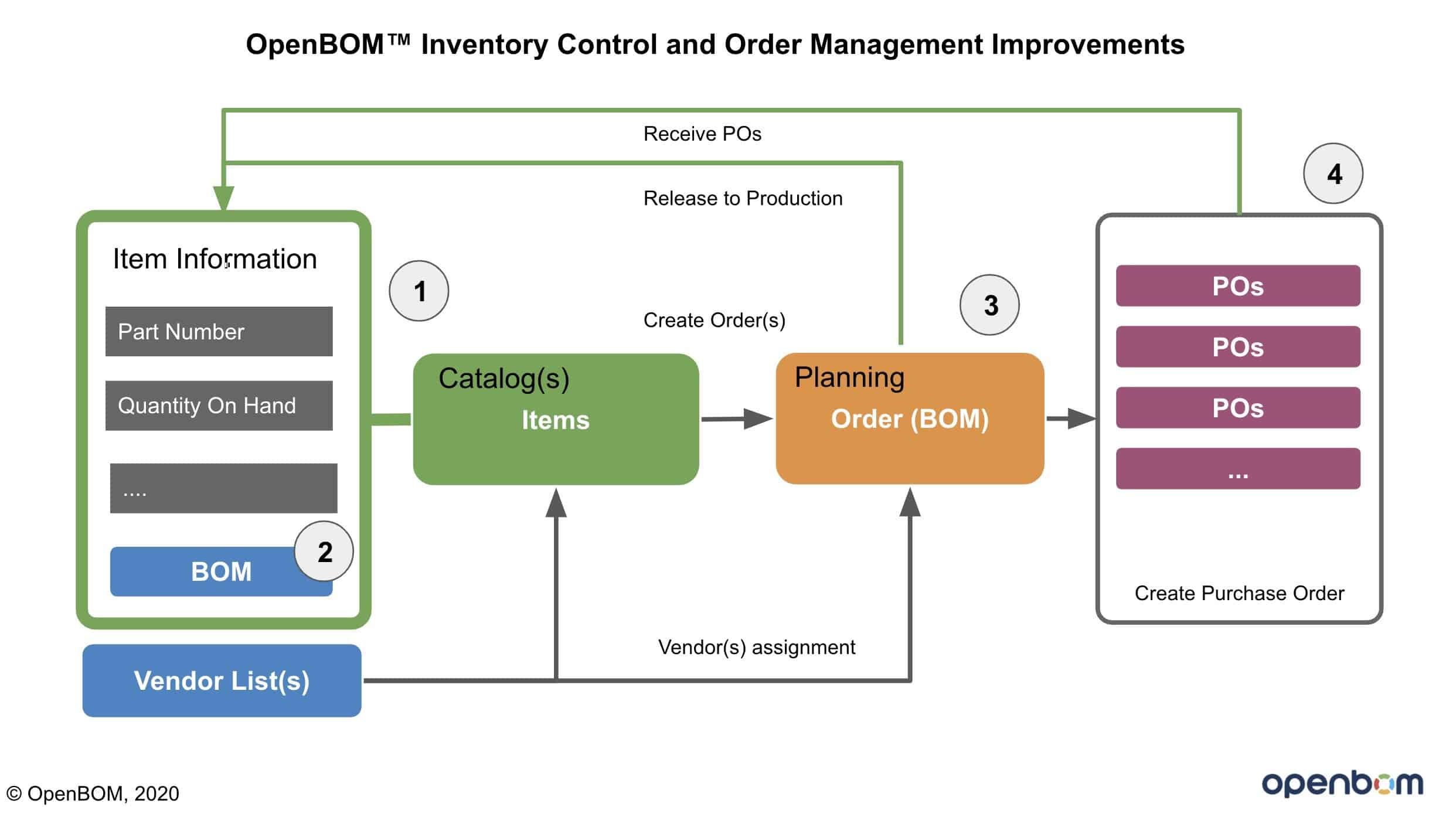

The picture below shows the overall process and business objects.

I will be covering four groups of enhancements related to Items, BOMs, Orders, and Purchase Orders.

1- Items

Item is becoming a more important element of the information than before. It centralized the information about everything in OpenBOM, which includes any item property (stored in the catalog) and the Bill of Materials (BOM) in case the item is assembly. Technically, Item can be anything in OpenBOM (material, part, assembly, labor) and it can include relationships with Bill of Materials. The properties of the item are fully customizable- you can create as many as you need using the standard OpenBOM property mechanism.

2- BOM (Bill of Materials)

BOM includes structured information about what item is composed of. The item might not have a BOM in case we are dealing with a single part or material. It is super simple to assign a BOM to the item using its Part Number.

3- Order (BOM)

This a process where major enhancements were happening. Starting from the new release, you can make an order for any item directly from the catalog. Which basically turns the catalog into a central place where you can start the ordering process. In case you are ordering a simple part, it will create an order with the number of units you specify when you create an order. But when you create an order for the item that has a BOM, the entire list of items will be scaled to the number of the units and placed in the order (the same command is also available directly from the BOM).

4- Purchase Order

Another place of big enhancements -we are introducing formal PO status and implemented receive function allowing to automatically update inventory by increasing Quantity On Hand in the catalog. This function will be closing the loop for inventory control and will allow controlling the process of stock replenishment.

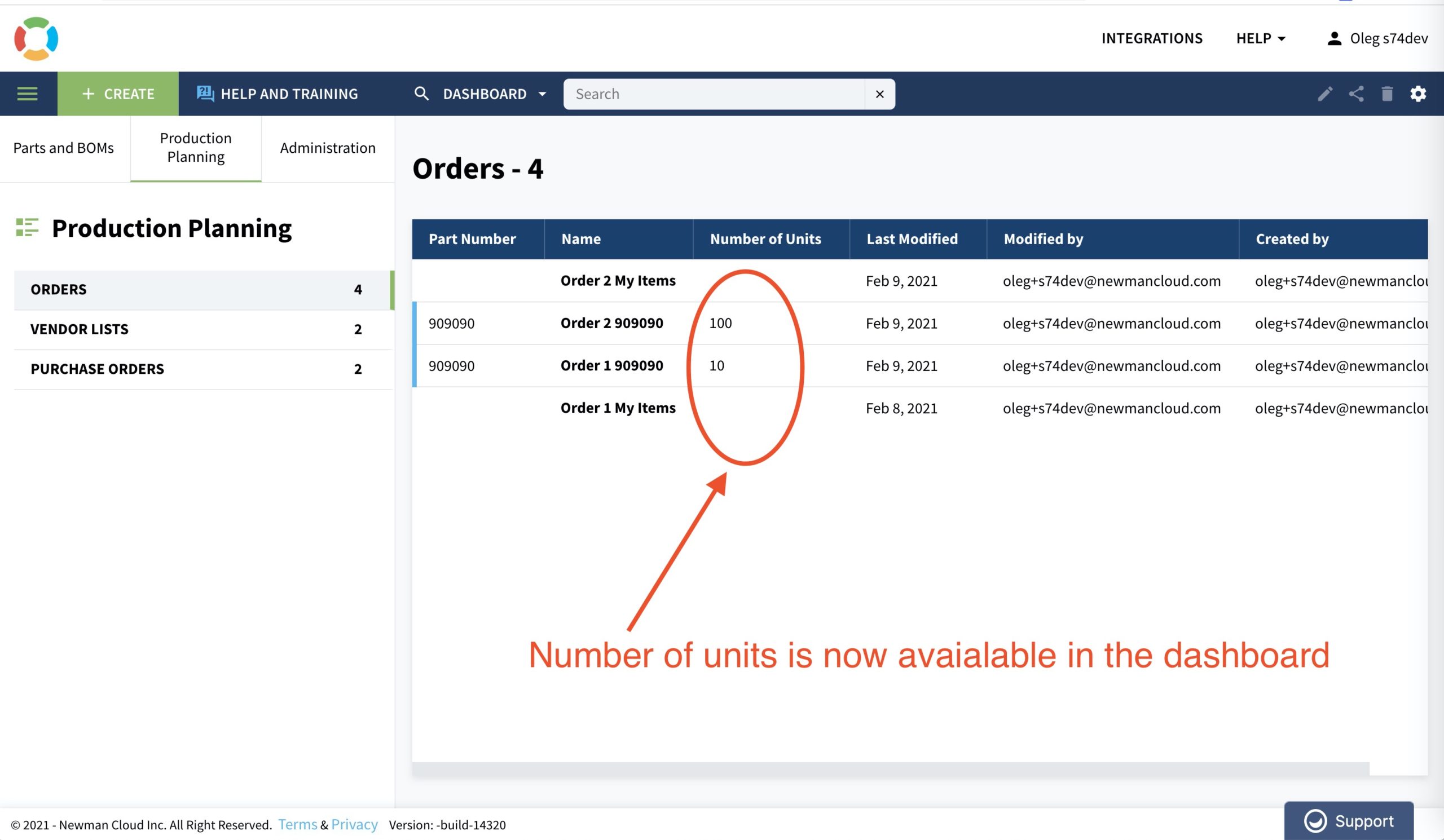

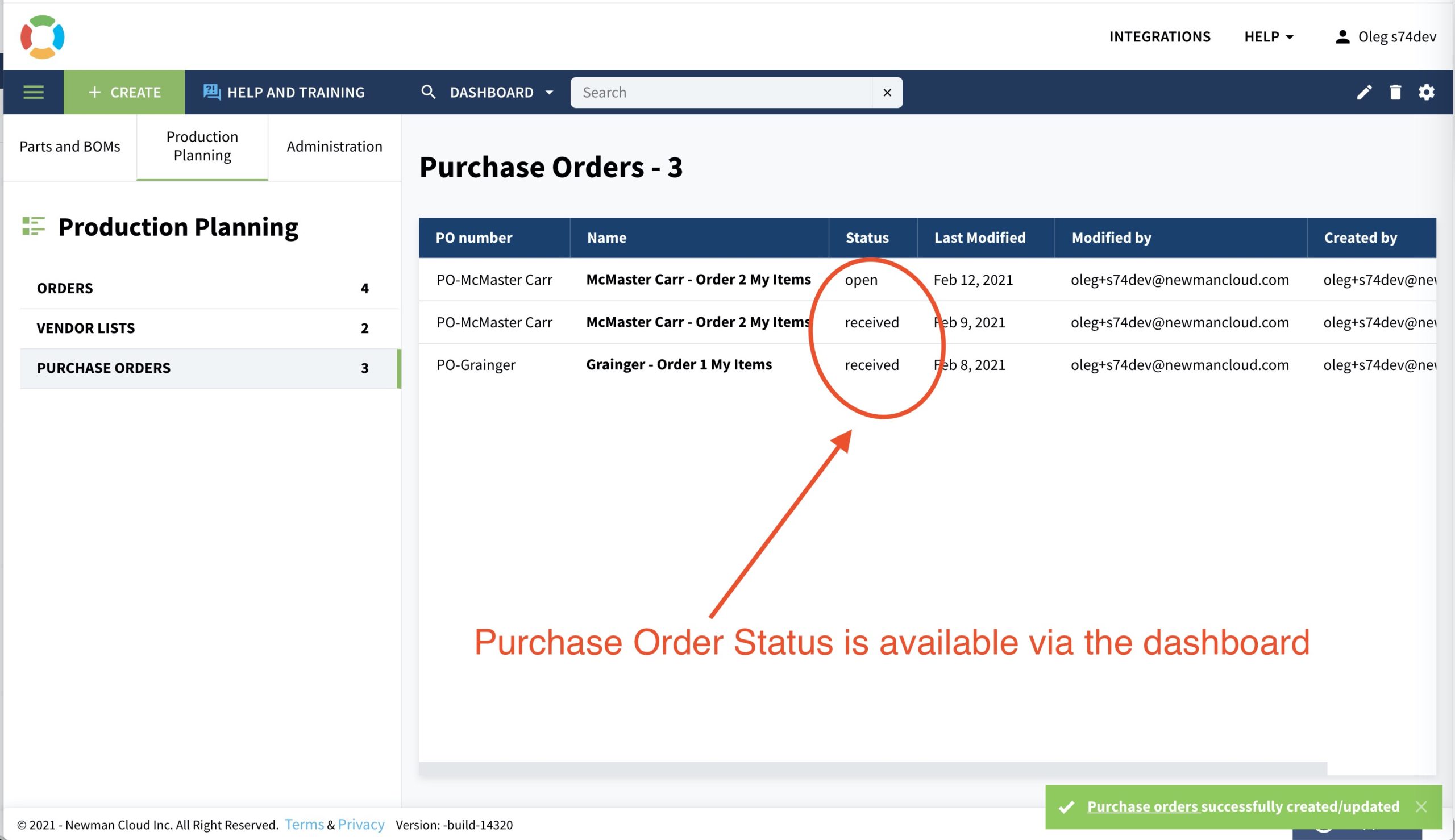

Dashboards improvements

We made few improvements in the way information is presented on the dashboards. The number of units for Orders created with BOMs is available now

For Purchase Order, the PO status is also available on the dashboard

Conclusion

I hope you will like the enhancements. All together it increases the robustness of OpenBOM to provide inventory control and purchasing solutions for companies engineering prototyping teams and medium-size manufacturing companies using Excel and spreadsheets as a manufacturing management platform. Integration with engineering design tools (CAD) and a powerful collaboration mechanism creates a unique blend of SaaS functionality to serve a diverse set of manufacturing and construction company’s needs.

Check what OpenBOM can do – REGISTER for free and start your 14-days trial.

Best, Oleg

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.