For every engineering team we work with, the first question about OpenBOM is “how to release a product”. In the world of traditional PDM/PLM systems, this process is usually document-driven and comes down to the routing of CAD files with some level of approvals.

At OpenBOM, we push the limits and are re-inventing this process with the ability to manage changes across multiple disciplines – mechanical, electronics, and software. To be able to do so is more critical than ever in modern manufacturing.

Whether you’re introducing a new revision of a part or rolling out a major product update, you need a controlled and collaborative release process that ensures accuracy, traceability, and team alignment.

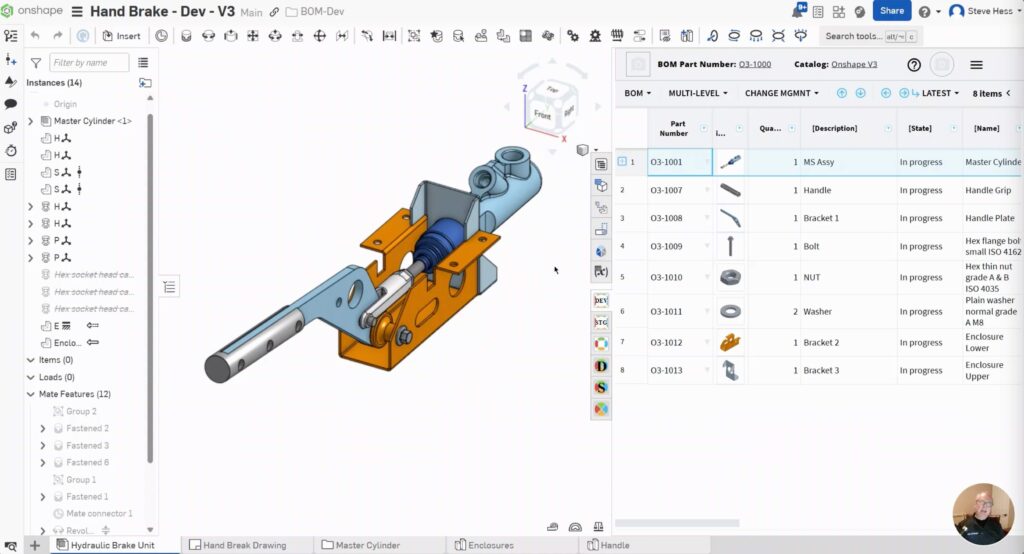

OpenBOM’s new Change Management capabilities provide exactly that: a structured, multi-step framework to manage, approve, and implement product changes with confidence.

What Is the Role of Change Management?

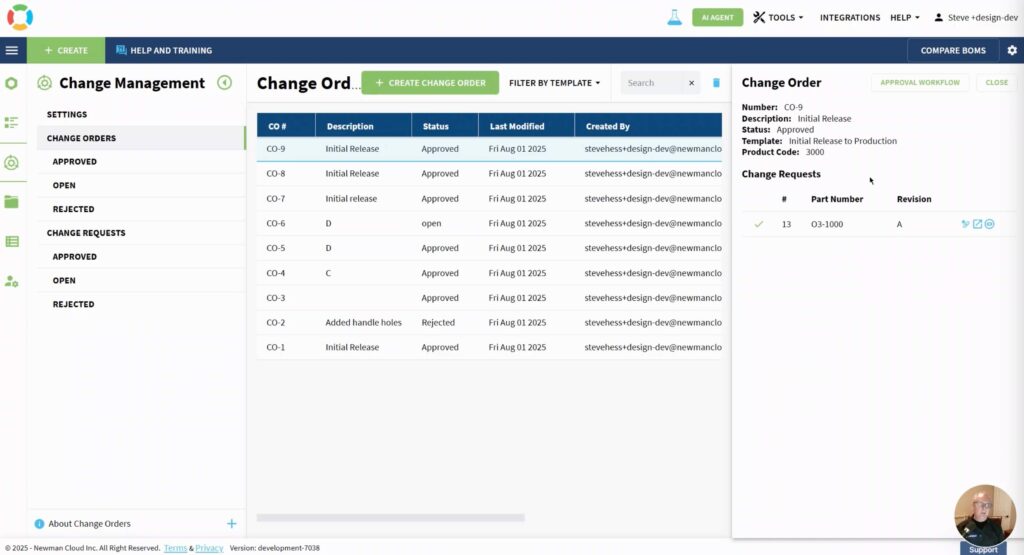

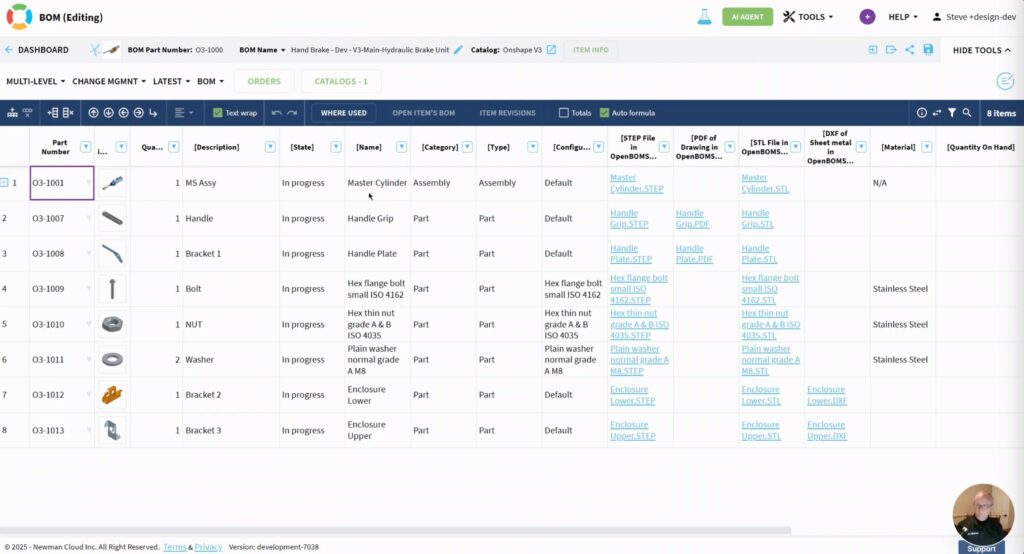

Change Management in OpenBOM helps your team plan, review, and approve product updates in a unified way. At the heart of the process is the Change Order (CO) — a formal container for all product changes. Inside the CO, you create Change Requests (CRs) for each item being modified—whether it’s a mechanical part, electrical component, PCB, or software artifact.

Each CO becomes a collaborative workspace where stakeholders review changes, assess impact, and approve updates in a controlled, auditable process.

The Change Management Workflow: Step-by-Step

Here’s how OpenBOM’s new release process works:

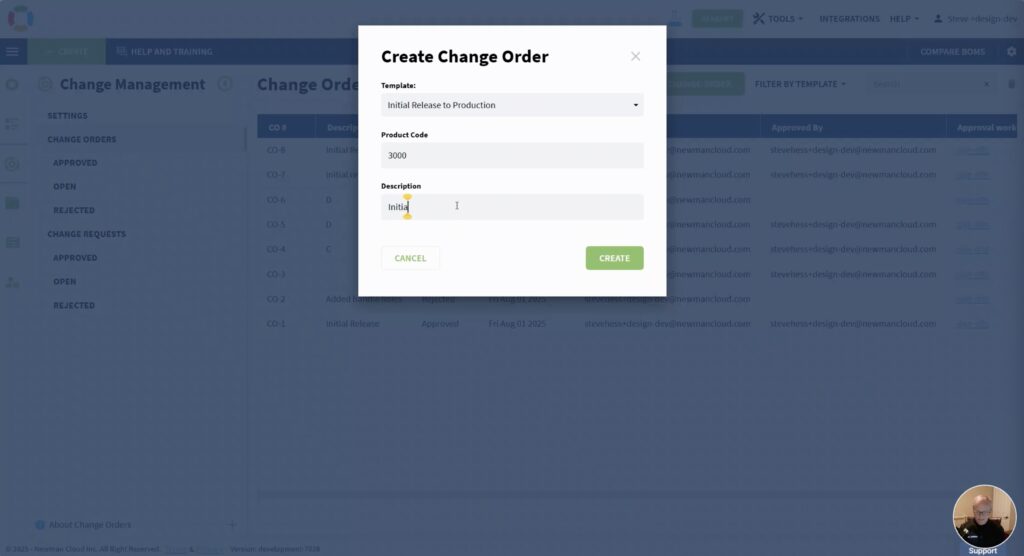

1. Create a Change Order

Start by creating a new Change Order, specifying the reason for the change, description, associated project, and other metadata.

2. Add Items and Change Requests

Select the items you want to include in the change—parts, assemblies, or even non-physical artifacts. For each item, create a Change Request, which includes the proposed change, notes, and target revision.

3. Review the Change and Structure

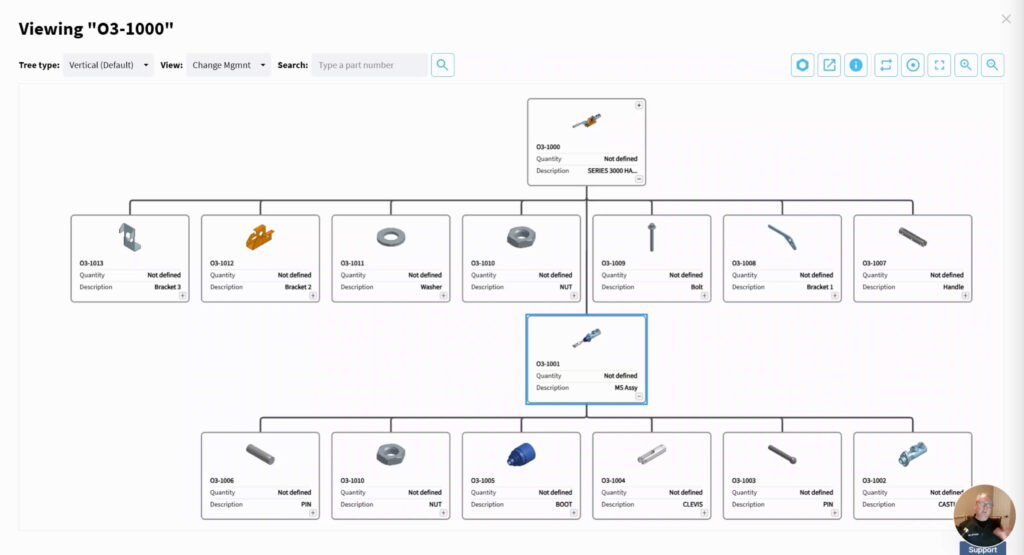

Review the entire structure and dependencies of the proposed change. OpenBOM lets you visualize how each item fits into the overall product and how it affects related assemblies and BOMs.

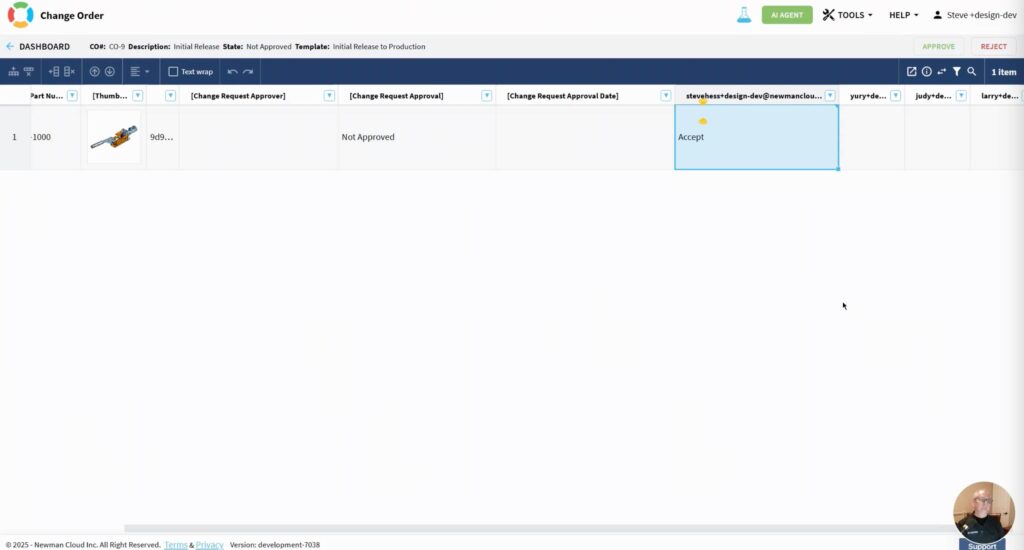

4. Route for Approval

Send the Change Order for review. Stakeholders and team members can collaborate and approve changes directly within OpenBOM. The process ensures that every voice is heard before any change is finalized.

5. Approve and Release

Once approved, OpenBOM automatically applies the changes:

- New revisions are created for each affected item.

- The Change Order is marked as approved.

- All related BOMs and product structures are updated accordingly.

A Unified, Multi-Disciplinary Framework

What makes OpenBOM’s change management approach unique is its ability to manage multi-disciplinary product data in a single, connected environment. From mechanical CAD files to PCB designs to embedded firmware components, everything can be grouped and managed in a single Change Order.

No more fragmented processes across systems. OpenBOM brings everything into one streamlined, cloud-native workflow.

Stay tuned for another video that includes mechanical + electronic change management together.

See It in Action: Change Management Demo

Watch the demo video to see how OpenBOM’s change management process works

👉 Watch the demo here

Conclusion

The improved OpenBOM Change Management process provides a robust, collaborative framework for controlled product releases. It empowers teams to:

- Work across disciplines

- Stay connected to their engineering tools

- Maintain full traceability of changes

- Ensure accuracy and consistency in every product release

As product complexity continues to grow, OpenBOM ensures your change management process grows with it, connected, scalable, and ready for the future.

Wait for more demos of improved change management functionality coming in the new OpenBOM release. Stay tuned…

In the meantime, REGISTER FOR FREE to try OpenBOM out.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.