In the past, when the product development process mostly meant designing mechanical structures, engineering teams were content to work within MCAD systems. Life was simpler: product designs lived in local files, managed by document-based PDM tools, and most teams worked in a single domain.

But times have changed. Modern product designs are no longer just mechanical. From smart thermostats and electric bikes to medical devices and industrial robots, today’s products are profoundly multidisciplinary projects. They blend mechanical structures, electrical components, embedded electronics, and increasingly, software.

Yet the systems and workflows used to manage this data haven’t caught up. For decades, product lifecycle management (PLM) tools focused almost exclusively on mechanical computer-aided design (MCAD). What about electronic computer-aided design (ECAD), printed circuit boards (PCBs) design, and software? Those were handled through side conversations, emails, or at best, scattered documents.

In modern product development, that lack of PCB, ECAD, and MCAD collaboration is no longer something electrical and mechanical design teams can afford to ignore.

The Challenge of Multidisciplinary Approach: PCB, ECAD, MCAD Integration

Take a look inside any modern engineering team, and you’ll likely find a patchwork of tools. The mechanical team might use MCAD tools like SOLIDWORKS or Creo, while the electronics group designs printed circuit boards in Altium Designer or Autodesk Eagle. Meanwhile, cloud-savvy engineers may work in ECAD tools like Onshape or Fusion 360, while software development resides in Git repositories.

Alignment of these tools is not easy. Some are cloud-native and cancollaborative; others still rely on desktop installations and file servers. This hybrid toolchain makes it difficult to keep everyone aligned, especially when changes happen fast and manufacturing decisions need to be made quickly.

Without a unified view, things fall through the cracks and design errors occur. A last-minute design tweak in ECAD software might not make it to the mechanical systems. Or a software component tied to a specific PCB revision could go untracked in the BOM. Multiply that across numerous electrical and mechanical engineering teams and product development cycles, and you’re looking at a recipe for rework and delay.

OpenBOM Design: Drive Innovation with a Unified CAD Integration

At OpenBOM, we’ve seen these challenges in the manufacturing process firsthand. That’s why we created OpenBOM Design, a mechanism to unify fragmented design processes and environments, bringing innovative products to market quicker and improving data exchange to minimize human error.

OpenBOM Design serves as a bridge between CAD tools of all flavors, including both traditional desktop applications and modern SaaS platforms. Whether you’re working in SOLIDWORKS, Altium 365, Siemens NX, Fusion 360, or Onshape, OpenBOM connects directly to your tools, extracts the data you need, and organizes it in a centralized, cloud-based workspace.

It goes beyond file management. You’re not just uploading drawings and 3d models; you’re capturing parts, physical structures, component placement, properties, configurations, engineering workflows, and relationships. Every file, every design change, every revision becomes part of a larger, intelligent ecosystem.

This means your BOM isn’t just a snapshot. It’s a living, evolving digital asset that reflects the true product design cycle as it changes and grows.

You can read more here:

👉 OpenBOM Product Lifecycle Management

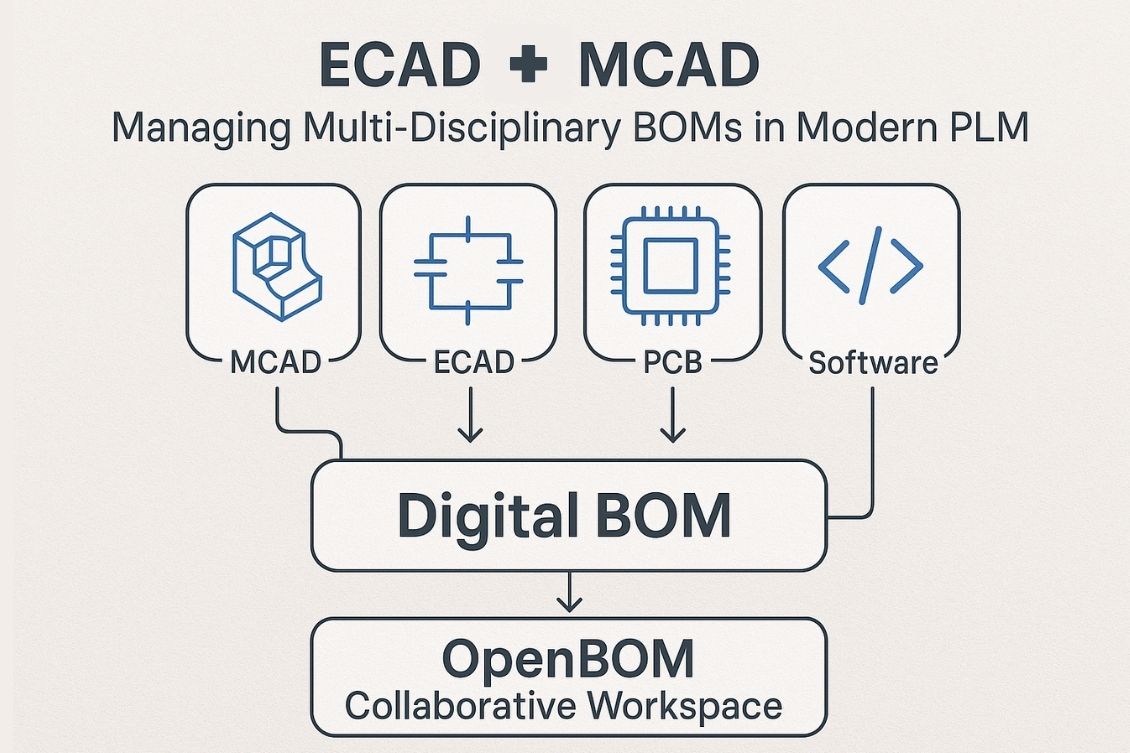

Digital BOM: The Core of Multi-Disciplinary Integration

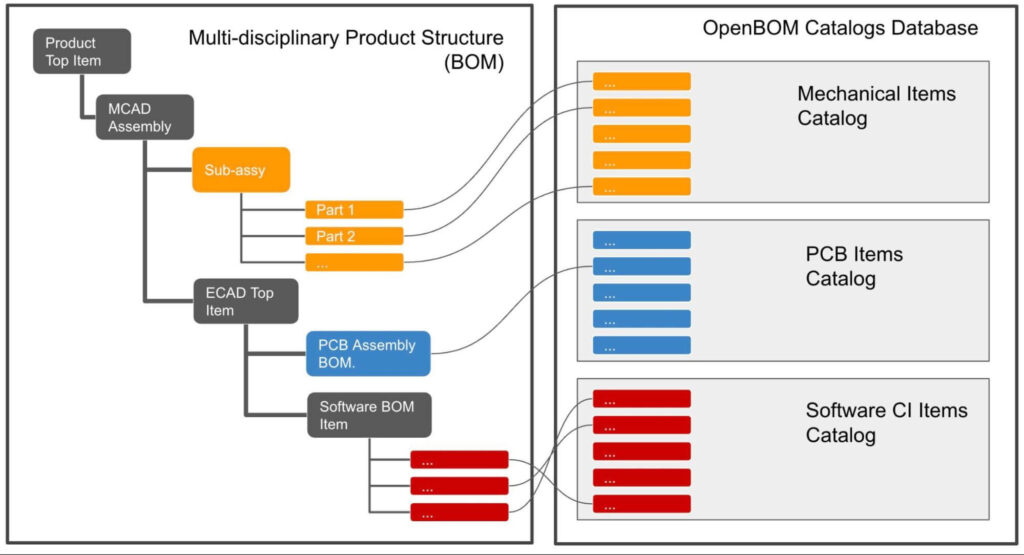

At the heart of OpenBOM’s platform is the concept of the Digital BOM. It’s a structured, searchable, and fully connected graph-based model of your product, spanning mechanical parts, electronic components, software packages, and everything in between.

Each element in the BOM is treated as an item, complete with metadata, references, versions, and lifecycle status. Whether that item originated in electronic and mechanical CAD doesn’t matter – OpenBOM enables seamless integration and brings it all together in a single system.

Perhaps more importantly, these items aren’t isolated. They live in what we call a Collaborative Workspace, a shared environment where both ECAD and MCAD teams can view changes, optimize designs, manage revisions, and work together without stepping on each other’s toes.

The workspace becomes your engineering command center, allowing you to manage change across domains, track the evolution of your designs, and ultimately, reduce errors before they happen.

Key Benefits of OpenBOM’s Unified Approach for PCB, Software/ECAD/MCAD Collaboration

Integrating MCAD, ECAD, and PCB design data into a single digital BOM offers more than just convenience – it transforms the way your teams work. Instead of waiting for emails, pinging colleagues for the latest file, or manually aligning spreadsheets, you get real-time clarity.

Your mechanical design team sees the electronic components they need to fit. Your electrical engineers and PCB designers are alerted when housing changes affect their PCB layout. Procurement teams get a holistic view of what needs to be ordered and what’s changed.

This level of visibility leads to fewer mistakes, faster iterations, reduced time to market, and better products delivered on time.

And since OpenBOM is cloud-based, everyone from suppliers to contractors to project managers can stay in sync, regardless of their toolchain or location.

Real-World Examples and Use Cases

One real-world scenario comes from teams using both ECAD and MCAD systems, such as Abram Scientific – a medical device company revolutionizing point-of-care diagnostic systems. Here is what they say.

“From the outset, it was clear we needed a modern, flexible, and integrated solution to manage our product data. After years of experience with traditional PLM systems, including Arena, we found what we were looking for in OpenBOM – a cloud-native, CAD-integrated platform that redefines what’s possible for startups building complex medical devices.

The following quote says it all:

“We discovered OpenBOM during a critical phase of our development cycle. From day one, it stood out as a truly modern alternative. OpenBOM doesn’t treat product data as a static archive – it treats it as a living, connected resource.”

“One of the most powerful capabilities for us is OpenBOM’s seamless ECAD/MCAD integration. Whether we’re using mechanical computer-aided design (MCAD) systems or electronic computer-aided design (ECAD) software, OpenBOM automatically pulls design data and builds a structured, multi-level BOM that reflects exactly what we’re designing.”

👉 Revolutionizing Blood Management Diagnostics: Why Abram Scientific Chose OpenBOM for Product Lifecycle Management

Conclusion: Embracing the Digital Thread

As products become more complex, the tools and processes we use to build them must evolve. It’s no longer enough to manage physical components in one system and electronic aspects in another. The future of product development and the electronics industry depends on breaking down these silos.

OpenBOM offers a new model, one where MCAD, ECAD, PCB, and software designs converge into a single, living, digital BOM. It’s the backbone of the digital thread, connecting teams, tools, and decisions across the product lifecycle.

FAQs

What is an electronic computer-aided design (ECAD)?

ECAD stands for electronic computer-aided design, also referred to as electronic design automation. It is a software used to create a functional design of electrical and electronic systems.

What’s the difference between electronic computer-aided design and mechanical computer-aided design?

ECAD and MCAD software are solutions that allow the creation of the virtual design of electronic and mechanical systems in products. MCAD focuses on mechanical structures like enclosures and frames, while ECAD handles developing electronic systems, which include printed circuit boards (PCBs), integrated circuits (ICs), and electrical systems. ECAD used 3d visualization to create a simulation of physical integration with mechanical enclosures.

Why is ECAD and MCAD collaboration important for PLM?

It ensures teams work from the same data, reducing miscommunication and improving product quality.

Can OpenBOM manage both cloud and desktop ECAD/MCAD tools?

Yes. OpenBOM connects to tools like SOLIDWORKS, Fusion 360, Altium 365, and Onshape to unify design data.

How does OpenBOM help with multi-disciplinary BOM management?

It brings all components—mechanical, electrical, and software—into one digital BOM, with real-time collaboration and change tracking.

If you’re looking to streamline collaboration, reduce errors, and get products to market faster—this is your chance to move beyond fragmented systems and into a unified, intelligent future.

👉 Start your free OpenBOM trial today

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.