During the life of your product, you will reach out to suppliers for quotes. This might be during your initial product launch, or you might be looking to change your supply chain after years of production. Regardless of the reason, the process to perfect your request for quotation (RFQ) is the same.

Before the process is defined we should outline the goals of the RFQ process. The obvious goal is to obtain a quote and compare it to others. However, there are multiple other questions that are asked to help you further evaluate your contract manufacturer (CM).

The RFQ process is an opportunity for your CM to not just provide a quote but show you its true value. The goal of the RFQ process is to not just receive their quote but to gauge their overall value. To do this, you need to answer the following questions:

- How was their communication?

- Did they offer any technical support?

- Did they quote this in an adequate amount of time?

- Did they provide a detailed quote?

Answering these questions helps you to understand whether or not they are a good fit. If you are able to answer these questions positively along with obtaining an acceptable quotation then the process was positive.

In order to answer these questions, you need to provide your CM with the appropriate product data. In order to answer the above questions, you should provide your CM with the following:

Bill of Materials (BOM)

The BOM is what holds a lot of the data of your product. The purpose of the BOM during the RFQ process is to be the main tool to transport knowledge from you to your CM. If your BOM lacks detail or is not accurate then there will be delays, inaccurate quotes, and an irritated CM.

Along with the basics, such as materials, finish, and color, the BOM should also include CAD files. Attaching derivative files will make it much more convenient for your CM to find everything, thus getting you a faster quote in return.

Assembly Steps

While the CM will offer support on the assembly steps, providing the assembly steps and a video would allow them to do a quick time study and provide a quick assembly cost. Many manufacturers wait until the last minute to get an assembly quote. This can catch them by surprise.

Quality Instructions

Similar to the assembly steps, the quotation is not finished until quality is included. While quality control and scrap for parts are included in the part cost, there might be a final quality check. If you need your product to be checked after assembly then outline this for your CM so they can take it into account for this.

Business Case

The business case is important because it outlines the potential for your product. It is also helpful for the CM to see if they can financially support it. Maybe your forecasted orders are too small or your orders are too large and there is too much financial risk for the CM. You should include the following in your business case:

- Preferred MOQ

- 12-month forecasts

- Target Price

A Prototype

Should you provide your CM with a prototype during the RFQ process? This is debatable, especially if you are not confident in them. However, if you are confident in their capabilities, then a prototype will help your CM to understand your product better and thus provide the best quote.

How to Pass this Data to your CM?

If you manage your BOMs on spreadsheets then you’ll need to make sure you have the most up-to-date BOM along with all of the necessary product specifications, CAD files, and more. During development, it is easy to lose track of revisions, and sending these during an RFQ process will result in not receiving an accurate quote or errors.

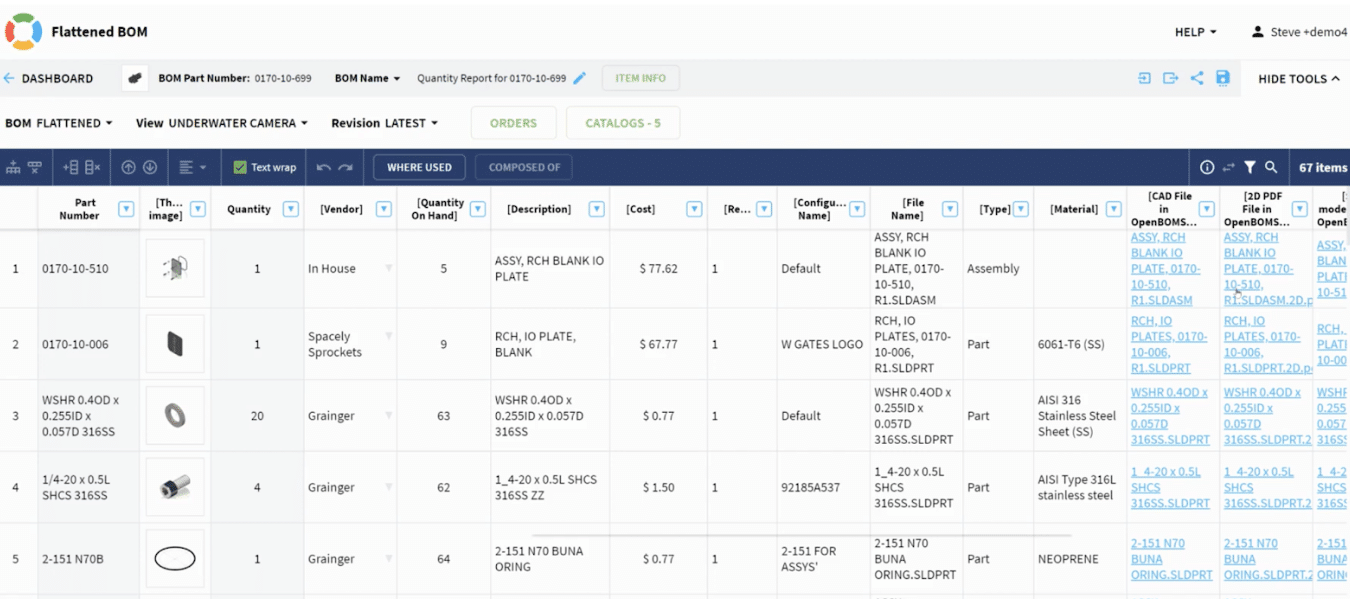

Even when you get into production, the only constant is change, and it’s a challenge to capture these changes using spreadsheets. The best way to pass data to your CM is through a centralized platform used to store all of your engineering and product data.

OpenBOM is a cloud-based PDM & PLM platform that allows you to manage your engineering and manufacturing data. Companies from startups to Fortune 500’s use OpenBOM to create a centralized database to bring in, store and manage their manufacturing data. With this infrastructure, users also use OpenBOM to streamline both their change management and PO processes.

If you need to improve the way you manage your data and processes, contact us today for a free consultation.

Regards,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.