Unless you lived under a rock for the last 10-15 years you’ve heard about contract manufacturing. This is a business model in which a firm hires a contract manufacturer (CM) to produce either a final product or elements of the product based on the finished design.

Through years of working as a contract manufacturer in China, I have found the bill of materials (BOM) as the most essential tool for manufacturing your physical product. But here is a problem I’ve seen many times. When I receive the BOM from the company that hires CM, it is lacking many pieces of information that is absolutely needed, some information is outdated or missed.

The results of this are:

- An inconsistent product.

- A poorly made product by leaving the part specifications up to your suppliers imagination.

- A longer than necessary transfer of knowledge process.

- Unknown lead times.

I often wondered why companies do not pay attention to their BOM when in fact it’s what creates stability and consistency in production.

Why is the MBOM Important?

When you create the engineering BOM (EBOM) it is not yet ready for manufacturing. You will lack certain specifications that are critical to ensure a successful product launch, followed by scalability and stability. My next blog will go into detail about the BOM’s journey. But for now, let’s go through it quickly.

A typical BOM you’re providing the CM is called an EBOM (engineering BOM). This BOM typically lacks many manufacturing details. To ensure a successful product launch, scalability and stability, your CM must turn your EBOM into the manufacturing BOM (MBOM). This MBOM is what holds the knowledge of how to make your product.

There are a few reasons why the MBOM is so important:

Creates Consistency

Let’s assume your MBOM is very specific and everything is called out correctly for each part. You can guarantee that each order will be consistent. You can even have multiple suppliers making the same product and have the same output.

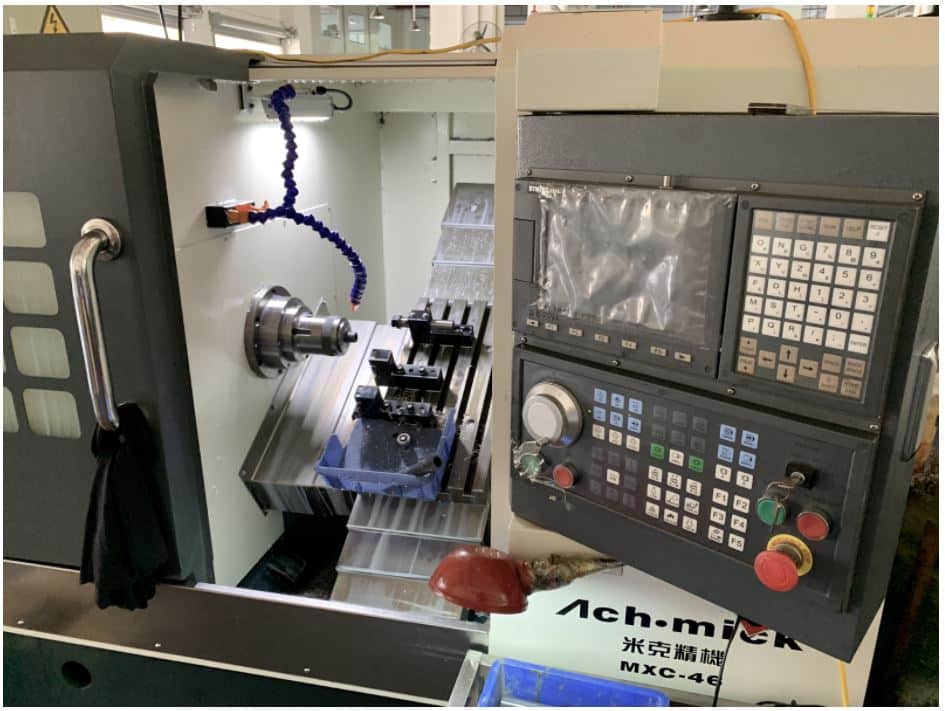

Let’s say for one part it needs to be CNC’d aluminum, which is then anodized blue. What you will receive will be aluminum 6061 that’s anodized to pantone 072C (darker blue) when you actually needed aluminum 7075 that’s anodized pantone 0821C (sky blue). You will see the part fails for two reasons, functionality and aesthetically. But does the part fail if it’s not specified?

Let’s look at another example. You have multiple vendors fabricating one component. Of course, you want all those suppliers to yield the same exact looking part. With a detailed MBOM, you will receive the same part. However, if your MBOM is not precise, you will receive inconsistent parts.

Cost Transparency

You should also receive a full BOM quote that will provide you with a quote associated with each item or part. This will quickly raise any red flags of parts that you feel are not priced correctly and you can launch a cost-down project.

There should also be extra items on the BOM, such as adhesives, tape, assembly, QC, and more. Each of these extra items that are not on the EBOM and should have quotes associated with them as well.

Lead Time Transparency

Similar to my previous point, the lead time should also be defined for each part. For example, you might be making an E-bike and all of your parts have a lead time of around 25-45 days. However, one part, the brakes from Shimano, has a lead time of 90 days. You quickly find out to get a better lead time, you will need to find an alternative supplier for the brakes.

Also, if you are managing a product, you’re actually managing the BOM. If the lead time is on the BOM, you will easily know how to be managing each part. If you are a bit picky, you can ask your CM to provide you with the lead time for each process, such as the amount of days it takes to procure the material, CNC the part, days to grind and polish and the days for anodizing. If one is delayed, you can plan appropriately.

Multiple other parts of your business are also directly tied to your lead time. Lead times will affect your forecasts, your payment terms (don’t want your cash tied up in inventory and work in process) and more.

Transfer of Knowledge

The BOM holds the knowledge for manufacturing your product. If you do not provide the appropriate amount of knowledge to your supplier to build your product, how can they build it to your expectations? If you do this because you are worried about IP, find another supplier or make it yourself.

Also during the RFQ process, you are passing the knowledge of your product to your CM. Failing to provide necessary information for the RFQ package will lead to quote delays, unnecessary back and forth, poor communication and more.

Let’s Purchase the Correct Parts and Items

This seems quite simple but the list of errors here can be quite long. If your BOM has the incorrect quantity needed for one part then you will either over buy or under buy. One will lead to an increase in inventory and the other will lead to not enough parts to fulfill your order.

On the other hand, let’s say one part on the BOM is an off the shelf motor you are purchasing from an OEM supplier. During the development process, you tried multiple different motors and finally found that motor 4 of the 6 motors you tried was acceptable. If your BOM has called out motor 6, you will purchase many incorrect motors. You can use this same example for the type of adhesive, bearings, actuators and many other mechanical and electrical components.

How OpenBOM Can Help?

At OpenBOM, we believe proper BOM management provides you with a consistent product. This is why we created a platform that revolves around the BOM. Your BOM is with you from the very start, such as creating a BOM from CAD all the way to creating a purchase order and everything in between.

Conclusion

Here is one thing I would like for you to take away from this article – do not underestimate your BOM. It will fire back. I like to say the BOM is the centralized document for manufacturing and again, your BOM quite often holds the knowledge for manufacturing. Meaning that if your BOM is wrong, your product will be wrong, or if your BOM is a bit subjective, your final product will be inconsistent. Your BOM is correlated to many other things, so let’s objectify this as much as possible.

Check us out at OpenBOM.com and don’t forget to sign up for our free, 14-day trial. Register to OpenBOM for FREE to check how OpenBOM can help you to manage consistent Bill of Materials and coordinate with contract manufacturers.

Best, Jared Haw

Jared.Haw at openbom.com

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.