There is a need for a rich and structured context.

Artificial intelligence has quickly become the buzzword in every boardroom, from Silicon Valley startups to traditional manufacturing enterprises. The promise is enormous: AI that can speed up decision-making, reduce human error, and deliver actionable insights in seconds. But here’s the uncomfortable truth: AI without structured, contextual data is little more than guesswork.

For most engineering and manufacturing companies, the problem isn’t AI itself. The problem is data. The product data needed to design, source, manufacture, and service a complex product is scattered across CAD files, Excel spreadsheets, legacy PDM/PLM databases, and ERP systems. None of these sources were designed to give AI the clean, semantically rich input it requires.

If the data is incomplete, messy, or unstructured, then AI will fail to provide reliable results. Instead of becoming a trusted assistant, it will hallucinate, miscalculate, or worse—produce recommendations that look correct but lead to costly mistakes.

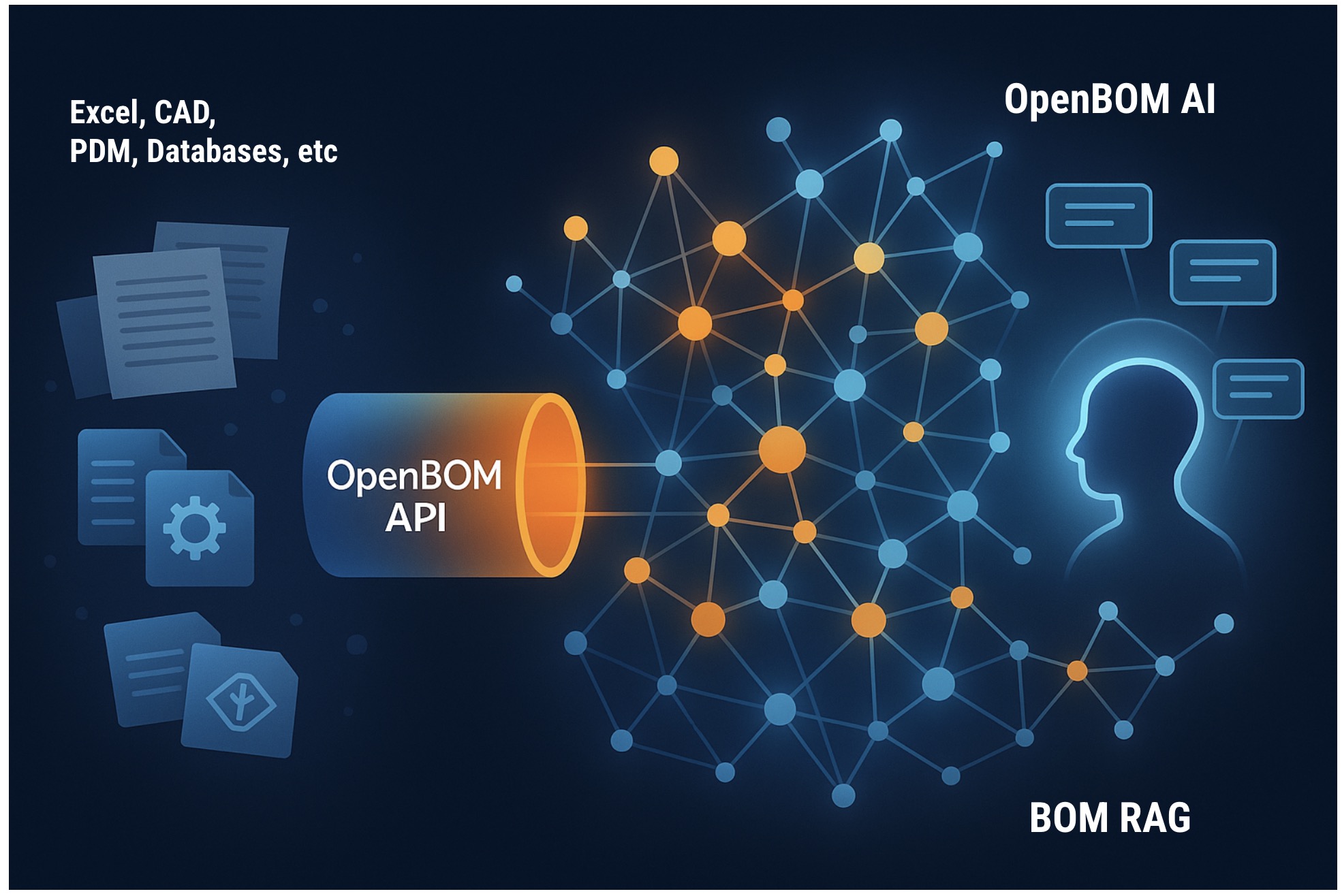

That’s why structured, customer-specific content is the foundation for any serious AI implementation in manufacturing. And this is where OpenBOM’s architecture makes the difference. By combining Unified Import, a robust API, and a graph-based data model, OpenBOM provides the context AI needs to move beyond chat and into outcome-driven results. The future of manufacturing AI depends on data that isn’t just stored—it’s connected, semantic, and ready for reasoning.

Unified Import as the Gateway

The first challenge every company faces when adopting AI is data unification. No matter how advanced your algorithm, if the data is locked in spreadsheets and siloed systems, AI has nothing to reason about.

OpenBOM’s Unified Import solves this problem by enabling companies to bring together data from:

- Excel and CSV spreadsheets

- CAD catalogs and design files

- ERP and MRP databases

- PDM vaults

- Legacy databases

Each of these sources speaks its own language, with its own quirks, property names, and formatting inconsistencies. Traditionally, importing them into one system requires manual cleanup, endless Excel formulas, and painful integrations. The result? Most companies give up, and their AI initiatives stall before they even begin.

OpenBOM’s Unified Import brings order to this chaos. It doesn’t just copy data; it normalizes it into a consistent semantic model. Each part number, property, and relationship is mapped into OpenBOM’s flexible schema, creating a single version of truth that can be queried, analyzed, and—most importantly—fed into AI pipelines.

This matters because AI thrives on clean, connected input. A language model may be able to guess from unstructured text, but in engineering and manufacturing, “guessing” is unacceptable. Unified Import ensures that when AI asks, “What’s the cost of all assemblies that include Part X?” or “Which suppliers are at risk if this component goes obsolete?”, the answer comes from a structured foundation, not a pile of guesswork.

OpenBOM API as the Bridge

Once data is unified, the next step is accessibility. AI cannot operate in a closed system. It requires a bridge to pull structured knowledge into its reasoning workflows.

That bridge is the OpenBOM API.

Think of the API as the gateway between OpenBOM’s semantic graph and external intelligence systems. Through the API, product data becomes programmable. Engineers, developers, or even AI agents can ask questions, retrieve subgraphs, and reason over specific contexts.

For example:

- A generative AI co-pilot can query OpenBOM to validate if a component exists in the approved vendor list before suggesting it.

- A procurement AI can calculate total quantities of a part across multiple assemblies, using the API instead of relying on brittle Excel macros.

- A digital twin platform can synchronize its virtual model with OpenBOM’s product structures in real-time.

The importance here is structured exposure. AI doesn’t need to trawl through PDFs or parse inconsistent spreadsheets. It can work directly with semantic data: assemblies, parts, revisions, suppliers, and lifecycle states.

This shifts OpenBOM from being “just a BOM tool” to becoming a data platform for AI. The API isn’t simply a way to extract tables; it’s a way to connect reasoning engines to structured product knowledge. That’s what makes outcome-driven AI possible.

Graph Model and BOM RAG

At the core of OpenBOM is its graph-based data model. Unlike traditional BOM systems that flatten data into hierarchical tables, OpenBOM treats BOMs as networks of connected objects.

Why is this important? Because real-world product structures aren’t flat. They are dynamic webs of relationships:

- An item belongs to multiple assemblies.

- A supplier provides multiple components.

- A revision links to both CAD files and change requests.

- A lifecycle state determines whether something is in work, released, or obsolete.

This network is inherently graph-shaped. And it’s exactly the structure that modern AI thrives on.

This brings us to BOM RAG—the concept of applying Retrieval-Augmented Generation specifically to Bill of Materials data.

- Retrieval: AI queries the BOM graph to extract relevant nodes and relationships — assemblies, parts, vendors, lifecycle states.

- Augmentation: The retrieved subgraph is enriched with supplier data, compliance rules, or cost estimates.

- Generation: AI uses this context to produce meaningful insights: risk reports, sourcing strategies, or impact analyses.

Instead of relying on static prompts or generic embeddings, BOM RAG ensures that AI always reasons within the structured, contextual reality of the product model. This is the difference between AI that chats and AI that acts.

Why Context is Critical for AI

Most manufacturing companies still manage BOMs and product data in spreadsheets. These flat, disconnected tables lack semantics. They don’t know what’s a part, what’s an assembly, what’s a revision is, or how they’re related. As a result, even basic questions become labor-intensive.

Take two common scenarios:

Quantity Rollups

Suppose you want to know how many resistors of type R-1001 are needed across five assemblies. In Excel, this means opening multiple files, performing lookups, copy-pasting counts, and hoping no one made a mistake. Errors are common, and results are often outdated.

In OpenBOM, quantity isn’t just a number in a cell—it’s a semantic property of a relationship between a parent and child item in the graph. That means a simple API query or RAG retrieval instantly produces an accurate total, ready for AI-driven procurement planning or cost estimation.

Where-Used Analysis

Now imagine a supplier announces that a part is going end-of-life. The critical question: “Where is it used?” In a spreadsheet world, engineers scramble across tabs and files, trying to piece together dependencies.

In OpenBOM’s graph model, where-used relationships are native. An AI agent running BOM RAG can instantly traverse the graph, list all affected assemblies, calculate the cost impact, and even recommend substitute parts.

These are not trivial calculations. They represent the difference between AI making vague guesses and AI providing actionable, reliable decisions. Structured semantics unlock AI reasoning. OpenBOM ensures those semantics are built into every import, every relationship, every API call.

PLM AI – Path Forward

What does this mean for the future of PLM AI? It means that OpenBOM is not just enabling companies to use AI, but it’s enabling them to use AI responsibly, contextually, and outcome-driven.

With Unified Import, API, and a Graph Model, OpenBOM provides the foundation for BOM RAG. Instead of “chatting” with generic knowledge, AI can work directly with the specific context of your product data. That means fewer hallucinations, fewer risks, and more measurable results.

This is the path from chat-based AI to outcome-based AI.

Imagine an AI assistant that doesn’t just respond with a text summary, but one that recalculates quantities across your entire product line, flags assemblies affected by a supplier risk, or generates compliance documentation on demand. That’s not science fiction—it’s the natural next step when you combine structured BOM data with retrieval-augmented reasoning.

The future isn’t about replacing engineers or procurement specialists with AI. It’s about giving them the tools to make faster, more accurate, more strategic decisions—powered by structured, contextualized product data.

Conclusion:

AI is only as good as the data you feed it. In manufacturing, that means structured, contextual BOM data.

OpenBOM’s Unified Import ensures data chaos from spreadsheets and legacy systems is normalized. Its API makes product knowledge accessible to AI agents. And its graph model transforms BOMs from static tables into living networks of connected information. Together, they create the foundation for BOM RAG, where AI can move from generic answers to outcome-driven results.

Without structure, AI hallucinates. With OpenBOM, AI delivers actionable intelligence—accurate quantity rollups, instant where-used analysis, risk assessments, and procurement insights.

If you’re thinking about AI in your engineering or manufacturing workflows, start with your data. OpenBOM gives you the foundation you need to make AI real, reliable, and valuable.

Want to try OpenBOM Unified BOM import today? REGISTER FOR FREE to check it out.

Want to discuss your future AI solutions with us? Contact our support.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.