Let’s be honest, most conversations about innovation and manufacturing gravitate toward sleek CAD models, breakthrough technology, or ambitious product roadmaps. But in reality, one of the most critical and often neglected – heroes of product success is the Bill of Materials.

BOMs are deceptively simple. On paper, it’s “just a list of parts.” In practice, it’s the DNA of your product. And like DNA, if there’s a mutation in the wrong place at the wrong time, the effects ripple through design, procurement, manufacturing, quality control, and customer satisfaction.

In this article, I’m going to look at ten BOM mistakes that can cost serious money, cause painful delays, and, in the worst cases, prevent your product from ever making it to production. I won’t talk about how to fix them just yet – that’s for another post—but I will walk through the real-world consequences these mistakes create, and why companies should treat BOM quality as a strategic priority.

Throughout, I’ll reference some deep dives we’ve published on OpenBOM’s blog and on Beyond PLM, where I’ve explored these pitfalls in detail.

Mistake #1: Treating the BOM as an Afterthought Until Manufacturing

I’ve seen this pattern over and over: over-engineering finishes a design, drops it on manufacturing’s desk, and assumes they’ll “figure out” the BOM.

The problem? By the time manufacturing digs in, you’ve already baked in part choices, suppliers, and materials without checking availability or lead times. This is where the first cracks appear: sudden price hikes, lead-time extensions, or suppliers who’ve quietly discontinued parts.

Think of it like planning a dinner party and only checking your pantry an hour before guests arrive. You will end up improvising, and not in a good way. (Bill of Materials Basics – What should be included in BOM and When to Start Working on BOM?)

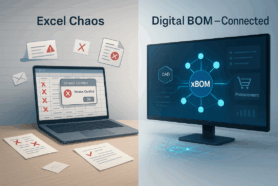

Mistake #2: Relying Solely on Excel and Spreadsheets

Spreadsheets are seductive because they’re quick, flexible, and universal. Everyone knows how to use them – until the team grows, the product gets complex, and you’re juggling 15 different files with similar names like:

BOM_final_v2_REAL_final_(use_this_one).xlsx

From there, things spiral—duplicate rows, broken formulas, mismatched revisions. I’ve talked to companies where procurement was ordering parts from one spreadsheet, engineering was updating another, and manufacturing was quietly working from their own local copy.

The result? No single source of truth, and a product that feels like it’s being built three different ways at once. Here’s a Beyond PLM perspective: BOM and Product Data in Excel – What’s for Breakfast?

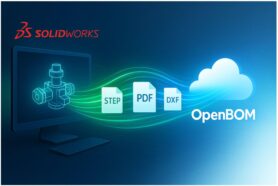

Mistake #3: Confusing CAD Output with a True Engineering BOM

Your CAD system might spit out a parts list, but let’s be clear- that’s not necessarily your engineering BOM (EBOM). CAD output often includes modeling artifacts, lacks non-modeled items (like adhesives or labels), and doesn’t reflect supplier or manufacturing realities.

And then there’s the other trap over-syncing. Not every CAD change should flow into your BOM. If you push every minor design tweak downstream, you create noise that overwhelms procurement and production, leading to change fatigue and missed critical updates. (How to avoid mistakes in Engineering BOM management)

Mistake #4: Poorly Managed Configurations

Modern CAD tools allow incredible flexibility with configurations—size variants, finishes, and optional features. But without strict naming conventions and clear rules, that flexibility becomes a liability.

Picture this: a SolidWorks model contains three configurations of the same bracket. Engineering intends to use the “2mm anodized” version. Manufacturing grabs the “3mm raw” configuration by mistake. The result? Parts don’t fit, assembly halts, and the whole lot needs rework.

This is a classic case of “the tool did exactly what we told it to—just not what we meant.” (A cautionary example from OpenBOM)

Mistake #5: Inconsistent or Duplicate Part Numbers

Part numbers are like street addresses—they guide you to exactly the right item. But when numbering is inconsistent, ad-hoc, or duplicated, you’re asking for trouble.

I’ve seen procurement order the wrong fasteners because two completely different screws were labeled PN-10025. And I’ve seen engineering teams waste days untangling whether “Upper Panel” in one BOM is the same as “Top Housing” in another.

Inconsistent numbering also corrupts reporting – your cost roll-ups, inventory counts, and sourcing data become unreliable. (Managing File Chaos and BOM Complexity: OpenBOM Lessons from SolidWorks Users)

Mistake #6: Missing Small Components

It’s amazing how often teams forget to include non-glamorous items like washers, adhesives, labels, or packaging in the BOM. These are the “silent” parts—you only notice them when they’re missing during assembly.

And when that happens, production stops. Or worse, someone substitutes “whatever’s on hand,” introducing inconsistencies or quality issues. Small components can have an outsized impact on reliability and compliance. (What Is The Cost of Bill of Materials (BOM) Mistakes?)

Mistake #7: Quantity & UoM Errors

Miscalculating quantities or mixing units of measure is one of the most frustrating (and costly) BOM mistakes. Ordering “1” when you need “1 per assembly” can multiply shortages across a batch run.

Likewise, mixing inches and millimeters or pounds and kilograms, without clear documentation, can result in incorrect materials being ordered or machined. These aren’t just clerical errors – they’re production disruptors.

Mistake #8: Incomplete RFQ Data

When sending a BOM out for supplier quotes, every missing spec is a chance for misunderstanding. Outdated revisions, vague descriptions, or absent material/tolerance data all lead to quotes that are inconsistent, unrealistic, or simply wrong.

The downstream effect? Delays in prototype builds, missed budget targets, and sometimes the need to re-source entirely. (Why RFQ quality matters)

Mistake #9: Treating BOM as a Static Document

Some companies still circulate BOMs as PDFs or printed spreadsheets. The problem? By the time they reach everyone, they’re already out of date.

In this model, each department starts making its own “local” updates, leading to multiple conflicting versions. By the time you try to reconcile them, you’re weeks behind, and nobody trusts any BOM as the truth. (Read more about collaborative BOM review)

Mistake #10: Revision Confusion

When you change something that impacts fit, form, or function, that assembly should get a new Part Number (or new revision) [we will not have those debates now :)]. Skipping this step (or bumping revisions for minor, irrelevant edits) is a recipe for chaos, liabilities, and sometimes death.

Without disciplined Part Number and revision control, you might have the shop floor working from “Rev A” while engineering is already on “Rev C.” And nobody knows which one to purchase. (Beyond PLM on revision triggers)

The Ripple Effect of BOM Mistakes

These mistakes rarely live in isolation. A missing part leads to a shortage, which triggers an unplanned supplier change, which changes the cost structure, which affects your margin model, and suddenly, your launch date slips.

The costs compound:

- Direct costs – expedited shipping, scrap, rework, overtime labor.

- Indirect costs – delayed revenue, damaged customer trust, increased warranty claims.

- Opportunity costs – market windows missed because you were fixing instead of shipping.

And perhaps the most dangerous cost: the erosion of team confidence. Once people stop trusting the BOM, they start building their own “shadow” versions. At that point, alignment across engineering, procurement, and manufacturing becomes a guessing game.

Recap: The Ten Costly BOM Mistakes

Here is the list of 10 mistakes that you need to keep in mind when you’re planning your strategy for BOM Management.

- Waiting until manufacturing to create/validate the BOM

- Spreadsheet chaos with no single source of truth

- Confusing CAD parts lists with a proper EBOM

- Mismanaged configurations leading to wrong builds

- Duplicate or inconsistent part numbers

- Missing “invisible” components like fasteners and labels

- Quantity and unit errors that disrupt supply

- Incomplete or outdated BOMs in RFQs

- Treating BOM as a static document, not a living model

- Poor revision control leading to version mismatches

Conclusion

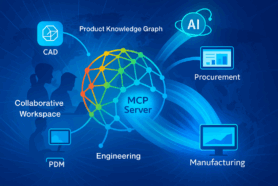

At OpenBOM, we believe BOM quality isn’t just a “data hygiene” issue – it’s a core enabler of product success. That’s why we’re pushing forward in two directions:

- Collaborative Review Functions

Allowing multiple users – engineering, procurement, manufacturing—to review and comment on a BOM simultaneously. This breaks down silos and helps spot issues before they cost time and money. OpenBOM Collaborative Workspace gives you a way to bring “All people on the same BOM” literally. - AI-Powered Quality Checks

Leveraging machine intelligence to scan BOMs for potential errors such as duplicate parts, missing quantities, outdated revisions, inconsistent units – so you can catch mistakes early, without relying solely on manual checks (Stay tuned here and talk to us).

If any of these BOM headaches sound familiar, let’s talk. Whether you’re stuck in spreadsheet chaos, battling revision confusion, or just curious how AI can help improve BOM quality, we’d love to hear your story.

You can find more about our approach in articles like:

- What Is the Cost of BOM Mistakes?

- Collaborate to Validate: Best Practices for Cross-Functional BOM Verification

Your BOM can be your greatest ally or your biggest liability. Which side of that line you land on is up to you.

REGISTER FOR FREE and check OpenBOM in real life.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.