If you’ve ever worked with modern CAD systems, you know that they bring both tremendous power—and a fair amount of complexity. One of the most powerful (and often confusing) features is design configurations.

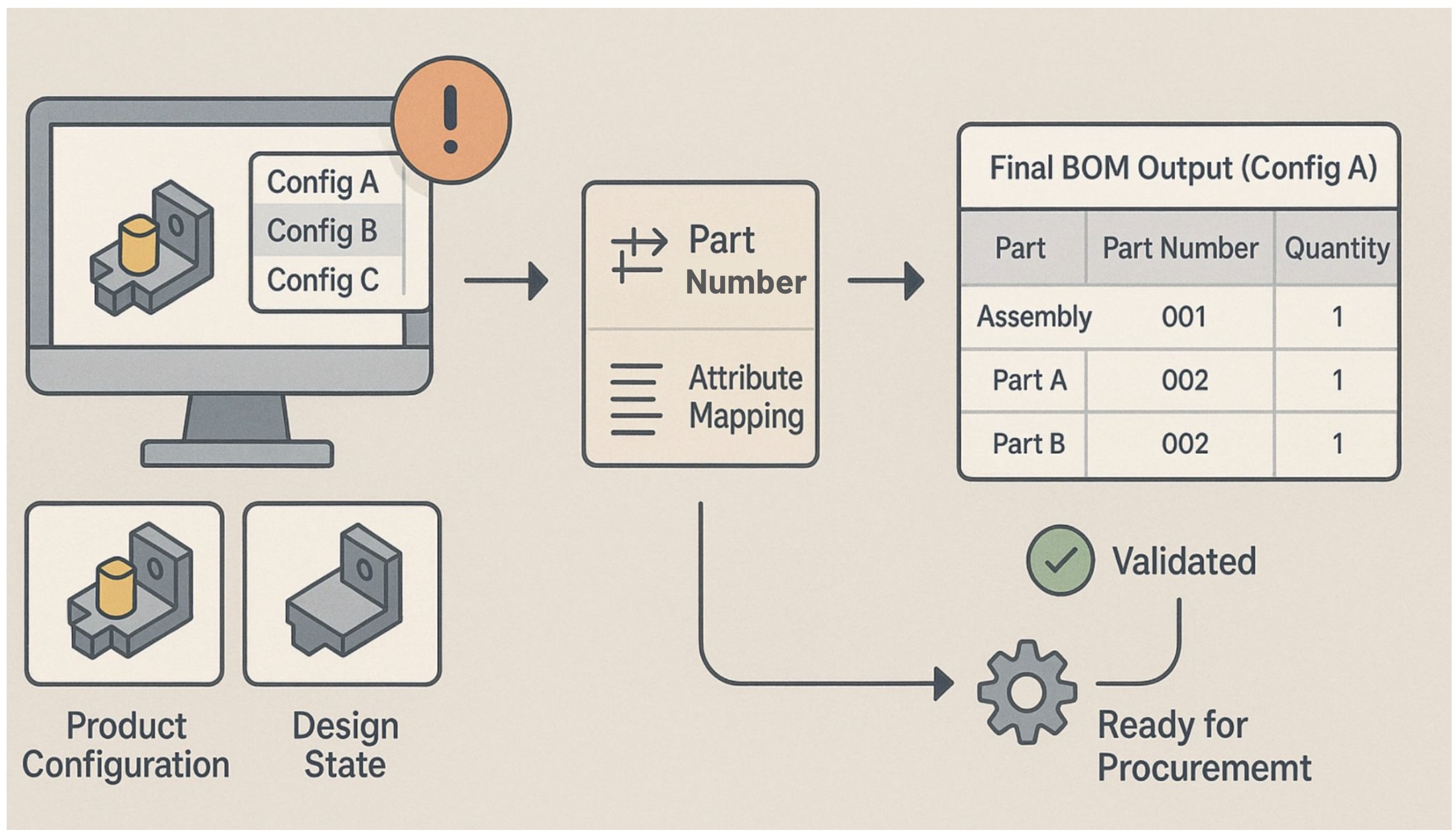

Configurations can represent a variety of things: different product variants, alternate positions of assemblies, sketch parameters, or just interim design states during development. For engineers, these configurations streamline the modeling process. But for procurement teams and BOM managers, they often introduce chaos—especially when it’s time to generate a reliable product structure.

At OpenBOM, we help companies bridge that gap. So today, let’s talk about best practices for managing design configurations and turning them into usable, structured BOMs.

The Problem: CAD Configurations ≠ Product Structures

CAD systems like SolidWorks, Autodesk Fusion, and others use configurations to allow flexibility in the design process. However, not all configurations are intended to become actual products. Some are used temporarily during the design process—for example, a mirrored assembly, exploded view, or a test sketch.

When it comes time to generate a Bill of Materials, it’s critical to distinguish between:

- Product configurations: Variants you plan to manufacture.

- Design process configurations: Temporary or visual configurations that should not affect the product structure.

Failing to distinguish the two can lead to duplication, incorrect part counts, or—even worse—conflicting part numbers for different variants. OpenBOM provides different settings allowing you to differentiate between two configurations of the same assembly and the same configuration used with the two positions (eg. open/close).

Key Principle: Part Number Alignment

To build a clear and accurate Engineering BOM (EBOM), you need alignment between CAD parts/assemblies and your product structure items.

The cornerstone of this alignment is consistent part numbers. OpenBOM allows you to control how part numbers are generated or mapped from CAD. But if multiple configurations share the same part number—while representing different geometry or purpose—you’ll run into problems.

Best Practices for Managing Configurations and BOMs

Here are four best practices we recommend when using configurations in CAD and managing them in OpenBOM:

1. Assess your use of configurations

Start by auditing how your team uses configurations. Are they creating product variants? Or are they capturing design states? Separate what belongs in a BOM from what doesn’t.

2. Configure part numbers properly

Make sure each unique part or configuration that needs to appear in a BOM has a distinct part number. This prevents mismatches and helps with traceability down the road.

3. Align attributes and properties

Set up your CAD-to-OpenBOM mapping rules so that key properties (material, revision, description, etc.) are aligned across the design and BOM systems. This ensures clean data flow and makes BOMs usable for procurement and manufacturing.

4. Generate the correct BOM per configuration

Use OpenBOM’s tools to resolve a specific configuration into a dedicated BOM. This gives you an accurate, versioned snapshot of that variant—with the correct part numbers and structure.

Where to read more? Here are a few articles:

- Optimizing SolidWorks: Best Practices for Design Configuration & BOM Management

- OpenBOM For Autodesk Fusion – Design Configurations Support

- How to start using OpenBOM with Onshape

Conclusion: Configuration Is Power—If Aligned With Data

Configurations are a powerful way to model variation and speed up design. But that power can quickly turn into confusion if your data is not aligned. With careful configuration management, proper part number assignment, and attribute alignment, you can turn CAD configurations into well-structured, usable BOMs.

At OpenBOM, we help you do just that.

If you’re struggling with configuration overload, let’s talk.

Meantime, REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.