As systems are becoming more complex, manufacturing companies and system integrators are facing an increased number of challenges. From modular data centers and wireless networks to mission-critical IT infrastructure, designing a system is never just about assembling a list of parts.

Earlier this week, I was talking to a company that is building complex wireless and radio networks. Their challenges are enormous, from building a system topology, defining materials and components, to the delivery and maintenance of the system. This is where OpenBOM comes with our simple yet powerful data management concept of xBOM with multiple Bill of Materials and structured datasets. Let’s talk about.

These companies need to create and manage a structured, evolving dataset — one that reflects the functional architecture of the system, supports operational planning, and adapts to procurement and deployment realities.

And what I can see with many of these companies – tons of Excel with tabs where these companies need to manage information, cross-link between materials, system deployment topology, and maintenance of the customer installation.

At OpenBOM, we’ve learned that most traditional tools fail to capture the true complexity of these systems. Spreadsheets become unmanageable. PDM systems are too rigid. ERP systems aren’t built to handle early-stage design or engineering flexibility. That’s why we created OpenBOM — a cloud-native, flexible, and collaborative platform that supports complex system design from components to deployment.

In this article, I want to explore how OpenBOM is used by engineers and planners to model and manage complex systems. I’ll focus on how our technology supports multiple structures, flexible data modeling, real-time collaboration, and integrated planning — all while helping you navigate complexity with ease.

Complex Systems: More Than Just Components

A complex system — whether it’s a wireless base station, a rack-based data center, or a remote edge computing module — isn’t a monolithic product. It’s a layered structure composed of interconnected components, each of which has its own lifecycle, vendor relationship, variant options, and functional context.

Designing such systems requires capturing multiple perspectives. For example, a single rack might be modeled one way for engineering, another way for production planning, and a third way for delivery and support. Add in location-specific constraints, different vendors for the same components, or changes over time, and suddenly your data model needs to do a lot more than just track part numbers.

OpenBOM treats complex system design as a data-first challenge. The system becomes a dataset — organized, structured, and accessible from every angle. Our customers in system engineering use OpenBOM not just to create a BOM, but to manage an evolving model of their entire system.

The xBOM Model: Capturing Multiple Perspectives

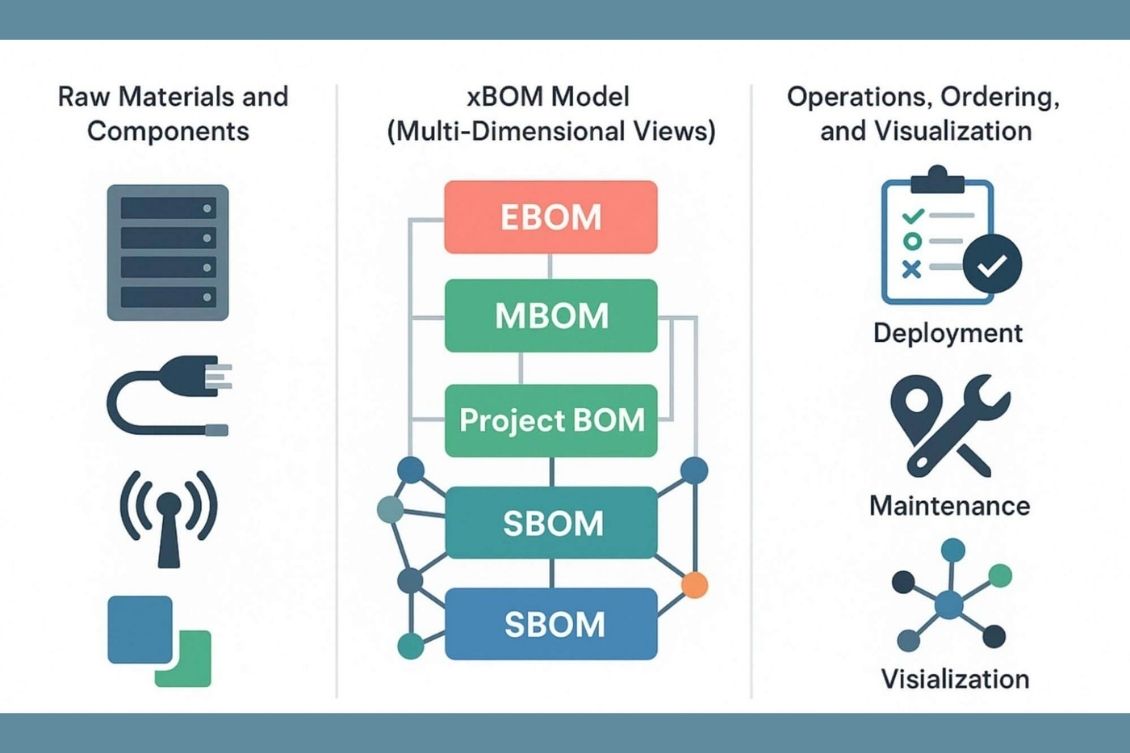

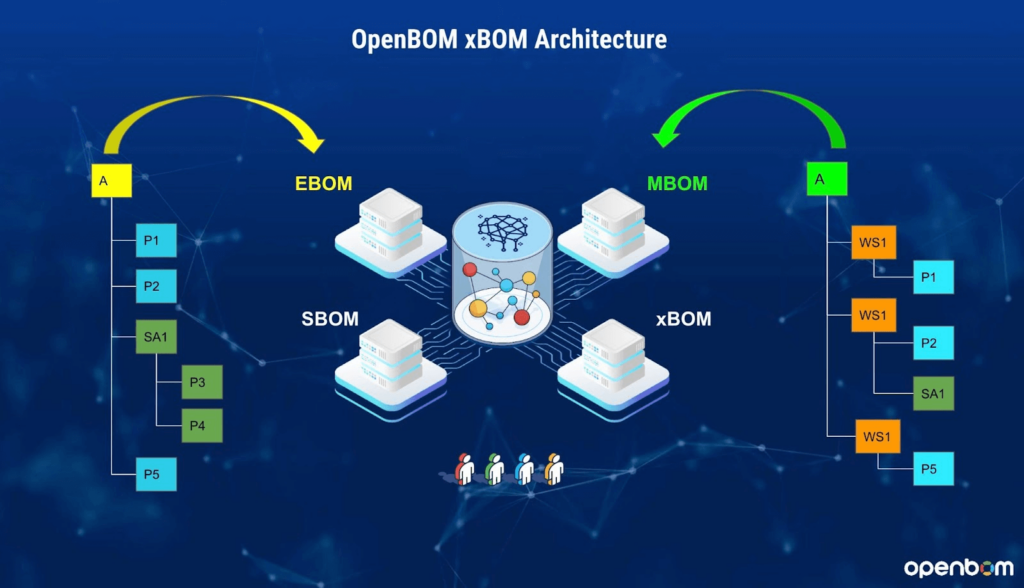

At the heart of OpenBOM is our xBOM technology — a way to define multiple BOMs (Bills of Materials) for the same system, each optimized for a different use case. We call this a multi-dimensional product model, and it’s critical for supporting the many ways a complex system must be understood and managed.

An engineering BOM (EBOM) might be organized based on the logical structure of the system — servers, switches, antennas, power units, software — with rich metadata attached to each item. Meanwhile, a manufacturing BOM (MBOM) could reorganize those same components based on how they are built, staged, or assembled on the production floor.

And when it’s time to deploy the system in the field, a delivery BOM might be broken down by project, customer site, or physical location. For maintenance, yet another BOM structure might be defined — grouping parts based on serviceability, replacement cycles, or firmware compatibility.

OpenBOM’s xBOM service allows you to create and link all these structures — not as separate spreadsheets, but as connected views into a single, cohesive data model.

Flexible Data Modeling: Your System, Your Metadata

To accurately represent a system, you need to go beyond predefined attributes. You need the ability to define custom properties — for each item, each structure, and each configuration. That’s where OpenBOM’s flexible data model comes into play.

You can model power ratings, cooling requirements, enclosure types, firmware versions, compliance data, network zones, mounting configurations — whatever is needed to make the system real and traceable. Every item in OpenBOM can carry these properties, and these attributes can be filtered, grouped, and searched dynamically.

This flexibility makes OpenBOM an ideal platform not just for engineering teams, but also for operations, procurement, and project managers. Everyone sees the data they care about, in the format that makes sense for them.

Modeling Delivery, Location, and Serial Numbers

System engineering doesn’t stop at design. Delivery, deployment, and operational readiness are essential parts of the system lifecycle — and these stages need structured data as well.

With OpenBOM, system designers can create structures based on project phases, geographic locations, or deployment plans. For example, when designing a network of modular data centers to be installed across several countries, each delivery location can be modeled as its own branch of the BOM. Each item can carry location-specific tags, serial numbers, and associated vendors.

This allows planning teams to track what is going where, who is supplying it, and how it fits into the bigger system picture. It also makes it easier to forecast procurement needs, schedule deliveries, and ensure that nothing is missing when the deployment team shows up on site.

Integrated Ordering and Procurement Planning

One of the most powerful features of OpenBOM is the ability to move from design to procurement and ordering in a seamless workflow. Once your system BOMs are structured, OpenBOM lets you assign approved vendors, enter pricing and lead times, and generate purchase orders automatically.

Instead of re-exporting BOMs into yet another spreadsheet and manually cutting POs, you can use OpenBOM’s planning tools to:

- Consolidate component needs across multiple structures or projects

- Batch components by supplier

- Track availability and costs

- Create real-time purchasing dashboards for your procurement team

Because all this is built on top of the same xBOM model, there’s no disconnect between what was designed and what is ordered. This eliminates a common source of errors in complex system projects — misalignment between engineering and sourcing.

Visualizing the System: Graph Navigation

With all this data, structure, and connectivity, how do you make sense of it?

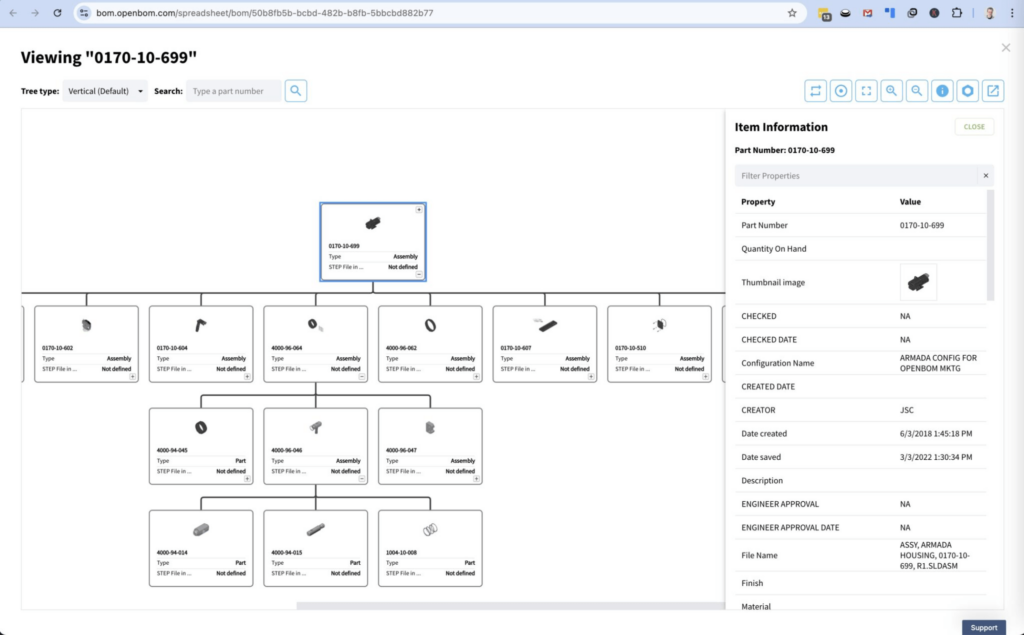

That’s where OpenBOM’s graph navigation comes in. Unlike flat spreadsheets or rigid tree views, graph navigation allows users to explore their system in a dynamic, visual way. You can see how components are connected, trace parent-child relationships, jump between subsystems, and follow links to external documents or referenced objects.

This kind of navigation is invaluable when debugging a design, preparing for a design review, or simply explaining the system to a new stakeholder. It turns your data into a living map — one that’s always current and always accessible.

A Practical Example: Wireless Network with Radio Stations

Consider a company planning to deploy a modular wireless network. Each pod includes compute units, power modules, cooling systems, and backhaul connectivity. Each deployment site has specific constraints — different power sources, climate conditions, or vendor contracts.

With OpenBOM, the system engineer can:

- Model a generic pod architecture (EBOM)

- Create variant structures for different regions (MBOM or location BOMs)

- Assign serial numbers and delivery dates by site

- Generate procurement plans for each region’s preferred suppliers

- Track the lifecycle of each component, from engineering to field maintenance

And because all of this happens inside OpenBOM’s unified environment, there’s no risk of miscommunication between the design, sourcing, and deployment teams.

Why Complex System Integrators Choose OpenBOM

OpenBOM is designed for engineers and planners who deal with complexity on a daily basis. Our customers appreciate that they don’t need to compromise between flexibility and control. With OpenBOM, they get both.

System engineers use OpenBOM to:

- Capture the full system architecture — not just parts, but how those parts relate to each other

- Build multiple BOMs that reflect real-world needs: design, production, deployment, and service

- Define their own data model with custom properties, relationships, and references

- Move seamlessly from BOM to procurement, without error-prone handoffs

- Visualize and explore complex system data in an intuitive way

Conclusion:

Complex system design isn’t getting any simpler. But with the right tools, it becomes manageable — even scalable. OpenBOM is built for the real-world challenges of system engineering. Whether you’re designing the next wireless backbone or a global edge computing platform, OpenBOM helps you organize, connect, and deliver.

If you’re involved in system planning — from material selection to architecture to field deployment — it’s time to rethink how your data works. OpenBOM gives you the foundation to create, structure, and navigate your system with confidence.

Ready to see it in action? Start a free trial or schedule a live demo at openbom.com.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.