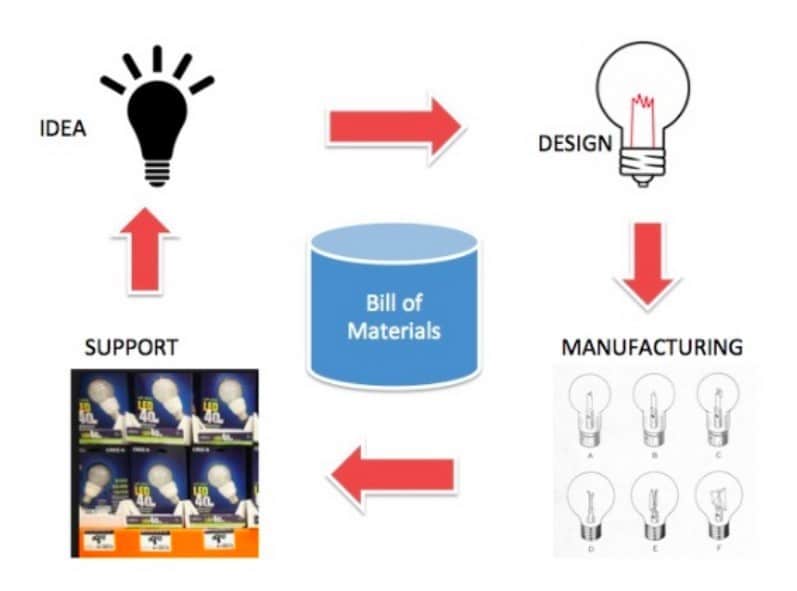

It has been a long time since I wrote blogs about the basics of BOM, Bill of Materials and BOM management. While it is pretty obvious that the Bill of Materials is a lifeblood of every since the manufacturing process, I found people are getting confused about how BOM management is directly connected to company business and profit. In the examples below, I’d like to give you a story of a typical discrete machinery shop. Think about building my favorite product – skateboard.

Let me start from the Cost of Parts and Assembly

In a nutshell, every manufacturing business is about to assembly some parts together, while making some of them by themselves. An average manufacturing company buys 70% of everything they put later together. This 70% of parts are better to be delivered to the assembly shop floor on time and with predictable cost. Otherwise, failure #1 – you pay too much for parts and you’re too late.

Let’s move to materials and assemblies preparation

Some of these parts need to be processed (eg. painted) before the assembly. Materials, time and labor should be included in the calculation of how much it will cost and how long it will take. You don’t have time, you don’t have materials, you spent too much time painting (or machining), you’re late, your total cost calculation went wrong, you’re coming to failure #2 – you pay extra to do labor, you pay to much to bring materials urgently and you’re late.

Finally, let’s make to the assembly process

To make assembly work done, you need to have some preparation work. Configuration and setup of machines, organizing assembly process. When you get an order, you should be able to calculate how much work will take to produce this amount of finished goods. So, labor, preparation work, parts, and materials should be ready. You don’t have enough parts or you didn’t calculate how much will take to assembly a single unit, you are coming to failure #3 – you pay extra to buy parts at the last moment, you hire more people to assembly or you need to reconfigure equipment to assembly special configurations.

What are the benefits of having an application like OpenBOM?

Here are my 5 reasons why OpenBOM can help you.

1- Single digital representation of the product, including a catalog with all components (parts, materials, assembly labor, etc.). Everything is collected, counted and organized. You know what parts you have and what amount of parts will be used in the product.

2- Cost control. You can stop guess and count and calculate everything you need. OpenBOM rollup costs will produce on-demand cost calculation using BOM and data in the catalogs. You change the cost in the catalog and everything is recalculated instantly.

3- Collaboration between people in different departments. OpenBOM real-time collaboration gives you a unique way to share data and allows everyone to see the information. Engineers, purchasing managers, shopfloor, customer and everyone else who need the information, will be able to get always updated information about product, its parts, cost and connect to the people using this data now.

4- Real-time inventory and purchasing planning. OpenBOM planning BOM (Order BOM) allows creating a planning list of purchases and outsourced work when order is coming. This is your shopping list and you will never miss anything you need. Moreover, you will know how many of them are on hands, which will allow you also to plan to purchase for future orders and not to be afraid of losing them.

5- Customer access to the BOM. Think about customers and maintenance problems. OpenBOM gives you a unique way to share BOM with your customers, By doing so, you will allow to customer to know exactly what is installed and what maintenance parts need to be ordered in case service and maintenance work is scheduled.

Conclusion

OpenBOM gives you a unique way to control BOM data, collaborate and purchase components and outsource the work. By providing a unique data management technologies, OpenBOM eliminates potential problems with the delivery, unexpected cost and helps you to organize the working process in a better way by streamlining the communication.

Check what OpenBOM can do today subscribing to OpenBOM here or request a trial version.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.