There are three typical manufacturing processes – built to stock, configure to order or custom product development (sometimes called engineering to order). Today, I want to talk about the last one that very often brings a lot of complexity in both design and manufacturing aspects of the process.

There are two main characteristics of engineering to order process – (1) design and other engineering activities are added to a product lead time and included in product development ; (2) when a company is signing a contract for custom development (ETO), all engineering requirements and related technical specs are not fully available. They will become fully available upon the completion of the design and engineering analysis.

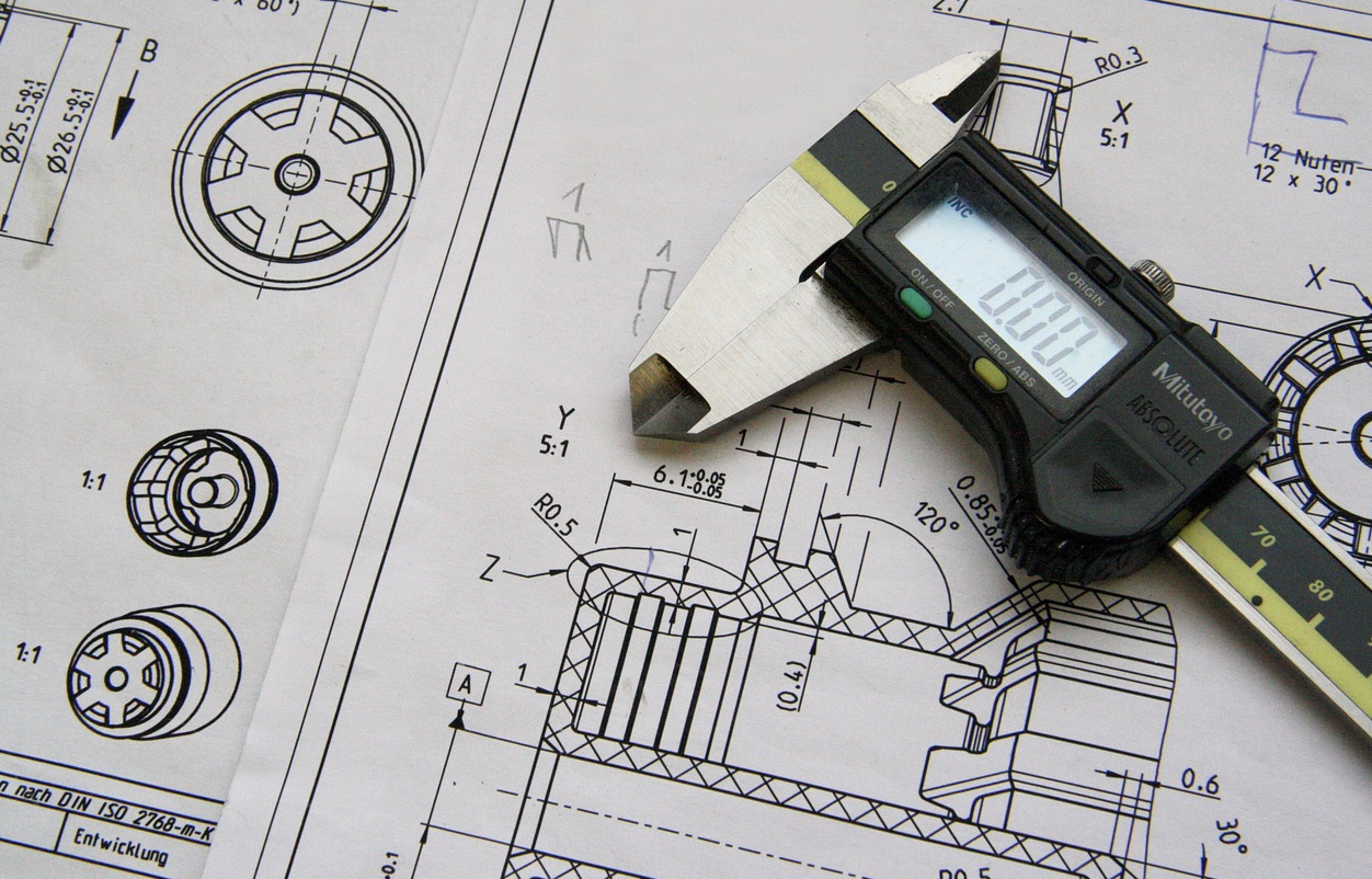

To make custom product development projects successful, you need to ensure the following critical technological enablers such as concurrent engineering, team collaboration, and lean production and manufacturing planning.

Here are the top three techniques you should be following in ETO:

1- To maintain the early visibility of the design and sharing information downstream. It will enable manufacturing planners, procurement and planners to work on long-lead components and contractor outsourcing.

2- To bring a system to support team collaboration, data sharing between design, production planning, purchasing, and the customer. Sharing data will help eliminate mistakes and decrease the number of risks during the later stages of integration, assembly, and shipment.

3- Design to purchase integration. Time is even more critical in custom development than in a traditional build to the stock of configuring to order models. Because of many unknowns, there is a need to perform purchasing of long-lead items or custom made parts earlier. Therefore, the demand for integrating purchasing and maintaining accurate design data is critical.

What is the role of the Bill of Materials in ETO. What special techniques needed to manage BOM for ETO projects? Later this week, we will be organizing an educational webinar to speak about Engineering to Order, best practices tools and techniques to speak about ETO and custom development?

Managing BOMs in an Engineer To Order process

WHEN: Wed, Feb 26, 2020 2:00 PM/

Does your company build a custom product based on customer demands? Often referred to as Engineer To Order (ETO), this process includes unique customer demands, short delivery, and multiple design cycles. Please join OpenBOM’s Director of User Experience, Steve Hess, as he presents a few techniques for managing a Bill of Material in an ETO environment. Have an ETO issue you would like to see included, please send it to support@openbom.com.

Conclusion

Products are getting very complex these days. And when it comes to custom product development, you need to have tools that capable to automate the process, share data and eliminate risk. Join the webinar to learn more about how to do so.

Best, Oleg @ openbom dot com.

Let’s get to know each other better. If you live in the Greater Boston area, I invite you for a coffee together (coffee is on me). If not nearby, let’s have a virtual coffee session — I will figure out how to send you a real coffee.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website

Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.