In today’s manufacturing and engineering world, the term multi-tenant triggers both questions and confusion. Product Lifecycle Management (PLM) has historically been dominated by single-tenant systems—solutions designed for one company, deployed on dedicated servers, and heavily customized to match each organization’s processes.

The Foundation of Modern SaaS PLM

Even as vendors began rebranding their systems as “cloud” PLM, most of these platforms continued to operate under the same single-tenant mindset. Their architecture still relied on SQL schemas and isolated data silos. While customers could configure and customize these systems, they lacked the true benefits of SaaS multi-tenancy – agility, scalability, cross-company collaboration, and lower cost of ownership.

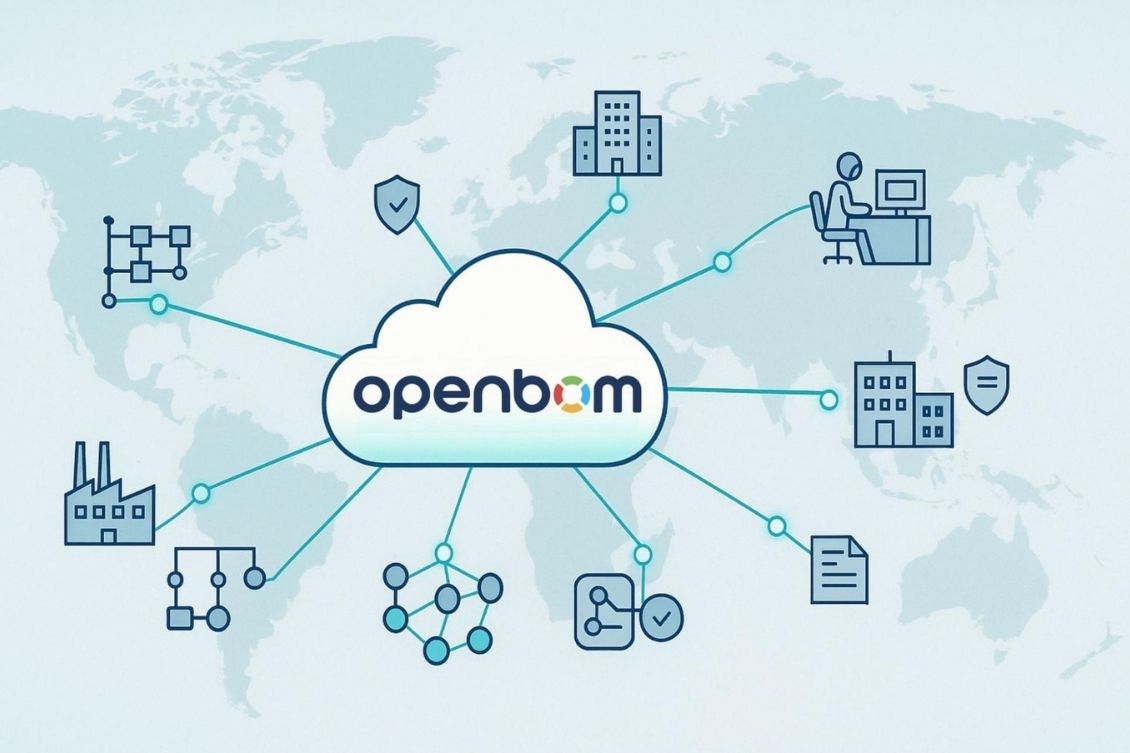

OpenBOM takes a different path. Designed with the “Google Doc” vision, it is a cloud-native, multi-tenant SaaS PLM platform. OpenBOM delivers a unique multi-tenant data model. It not only allows every tenant to configure and customize its data flexibly, but also enables secure data sharing across tenants in real time. This is a complete rethink for how companies collaborate and build digital threads across supply chains.

What is a Multi-Tenant Data Model?

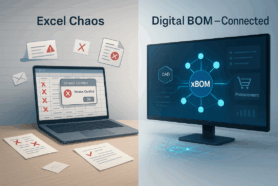

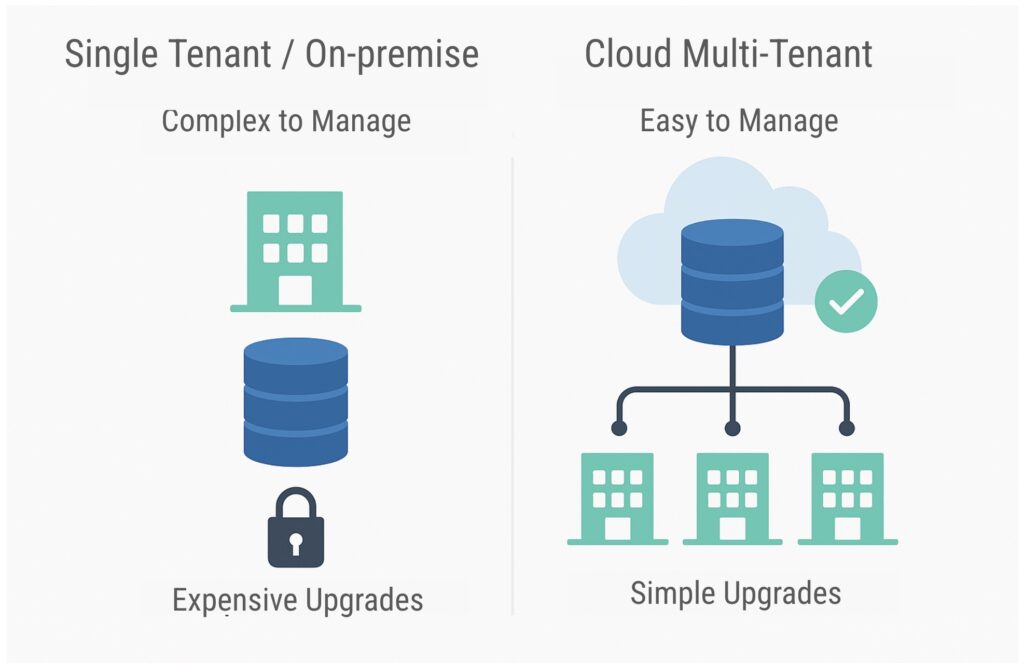

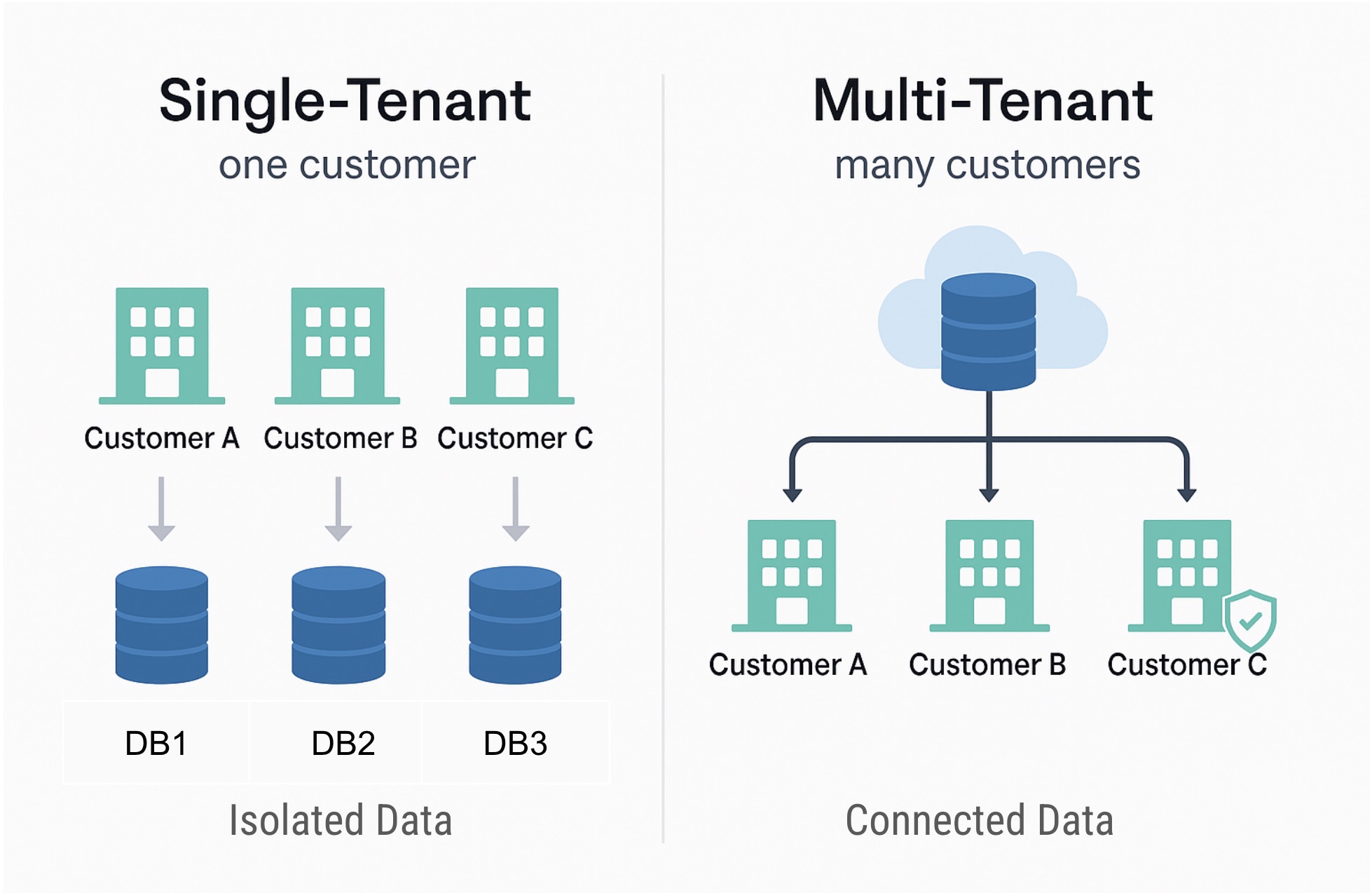

To understand why this matters, it’s useful to compare single-tenant and multi-tenant systems. In a single-tenant architecture, each customer has its own software instance, database, and configuration. Updates and maintenance are isolated, but so is the data. Collaboration requires duplicating or exporting information across portals and integrations (or export/import operations). This approach often leads to higher costs, slower scaling, and limited ability to connect with external partners.

A multi-tenant system, on the other hand, allows all customers to share a single software instance and infrastructure, while maintaining secure, isolated data spaces. Updates are delivered instantly, costs are spread across users, and most importantly, the architecture enables seamless connections across tenants when needed.

However, there is an important distinction. Many so-called multi-tenant systems in PLM are simply multiple single-tenant databases running in the cloud. This is not a full benefit of multi-tenancy models. A genuine multi-tenant data model is shared at the core. It is designed for flexibility, scalability, and connection, rather than duplicating infrastructure for every customer.

The advantages of multi-tenant PLM are significant. Companies gain scalability because the system can expand automatically without provisioning new servers for every customer. The shared infrastructure reduces IT costs. Updates happen continuously without disruption, ensuring that every customer benefits from the latest capabilities. Perhaps most importantly, true multi-tenancy enables secure cross-tenant collaboration, allowing data to flow across company boundaries. The architecture is ecosystem-ready, supporting networks of suppliers, contractors, and manufacturers who need to collaborate in real time.

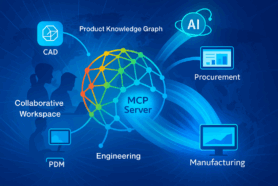

OpenBOM takes this concept further by combining multi-tenancy with a graph-based data model, which is semantically rich, flexible, and capable of representing complex product relationships.

OpenBOM’s Flexible Data Model Explained

Most legacy PLM systems rely on SQL schemas – table-based data models that although super mature and well known, cannot scale well to manage complex structured product information. These schemas can handle structured data but quickly become cumbersome when companies need to represent new types of data or relationships.

OpenBOM takes a fundamentally different approach. Its graph-based data model allows virtually unlimited flexibility. Every component, assembly, or system can be represented as a node in the graph. Catalogs and documents can be linked directly to items, and suppliers or vendors become part of the same connected structure. The model is not limited to a single view of product information but can support multiple perspectives simultaneously. This is why OpenBOM can seamlessly manage Engineering BOMs, Manufacturing BOMs, Service BOMs, and Software BOMs in one system and, at the same time, keep flexibility and configurability of the system for each tenant.

The power of this model lies in the semantic richness of the graph model and the ability to traverse complex product information. Engineers can represent both EBOM and MBOM in a single graph model and filter out the right type of relationships. A procurement manager can explore supplier relationships directly connected to parts. A quality manager can analyze the impact of a design change across assemblies and suppliers. All of this happens within a single connected system.

This graph-based foundation also supports the creation of the digital thread. Instead of living in disconnected silos, product data is woven together into a navigable, connected structure. And as the industry moves toward AI-driven workflows, a graph data model provides the semantic richness needed for advanced reasoning, recommendations, and automation. OpenBOM is not only solving today’s challenges but also laying the groundwork for AI-powered product data management.

System Configuration in OpenBOM

Flexibility in OpenBOM extends beyond the data model and into the way companies configure the system itself. Unlike traditional PLM deployments, which often require IT work and consulting, OpenBOM provides self-configured tools that are accessible to customers.

Users can define properties and data types to capture custom attributes. They can create item types and classifications to organize data across disciplines such as electronics, mechanics, and software. Views can be tailored to present the right information to engineering, manufacturing, or procurement teams. Permissions and roles can be assigned to ensure the right people have the right level of access. And all of this is backed by powerful data sharing capabilities that allow teams to collaborate both internally and externally. Even more, engineering and design configurations and integrations automatically generate data models on the fly using CAD add-in system configuration tools.

Because OpenBOM is SaaS-native, these configurations happen in real time. Accounts can be created instantly, and changes propagate without downtime or complex deployments. Companies are not locked into rigid schemas—they can adapt their data model and system behavior as their needs evolve. This agility is especially valuable for SMBs and mid-market companies that need enterprise-grade PLM capabilities but lack large IT departments.

Sharing Data Across Multiple Tenants

One of the most important differentiators of OpenBOM is its ability to support data sharing across multiple tenants. Traditional PLM systems create a hard stop at the company boundary. Data must be exported into portals, supplier systems, or spreadsheets to move across organizations. This duplication creates delays, introduces errors, and breaks the continuity of the digital thread.

OpenBOM removes this barrier. Its multi-tenant architecture allows secure, controlled sharing of data across tenants. A manufacturer can share an engineering BOM directly with a contract manufacturer. That contract manufacturer can extend the BOM with manufacturing data, supplier links, and costs, and then share it back. Updates flow in real time, and both parties remain connected to the same digital thread.

Consider a practical example. A medical device company designs a new product in OpenBOM and shares the EBOM with its contract manufacturer. The contract manufacturer adds the MBOM details, assigns suppliers, and calculates costs. Both organizations remain synchronized without exchanging spreadsheets or logging into disconnected portals. The digital thread extends naturally across company boundaries, saving time and reducing risk.

This capability represents a fundamental shift. Instead of every company running its own isolated PLM system and relying on brittle integrations, OpenBOM enables a collaborative network model where data can securely flow across the supply chain.

Why Multi-Tenant + Configurability Matters

When combined, multi-tenancy and configurability create a powerful advantage for companies of all sizes. Multi-tenancy lowers IT costs by eliminating the need for dedicated servers and complex upgrades, while configurability ensures that each company can adapt the system to its own needs without lengthy customizations. Together, they enable faster adoption, since new accounts can be provisioned instantly and configured by users themselves.

For SMBs, this combination provides access to enterprise-grade PLM capabilities without enterprise-level budgets. Companies can start quickly, configure the system to match their processes, and scale as needed (you can register an OpenBOM account online and have it ready to use in under 1 minute). For large enterprises, the combination delivers agility and connectivity. They can connect suppliers, contractors, and partners into the same digital thread without investing in custom portals or integrations.

Continuous updates are another critical benefit. OpenBOM delivers improvements seamlessly, ensuring customers always benefit from the latest capabilities. For organizations that require validation, controlled update options are available to ensure compliance. This means companies can innovate without disruption while maintaining trust in their systems.

Conclusion: Building the Future on a Modern Backbone

The manufacturing industry is at an inflection point. Legacy single-tenant PLM systems, even those labeled as “cloud-enabled,” cannot meet the demands of global, connected supply chains. The future requires platforms that are multi-tenant, configurable, and capable of extending digital threads across organizations.

OpenBOM delivers on this vision. Its true multi-tenant data model, powered by a flexible graph-based structure, advanced system configuration, and cross-tenant data sharing, creates a foundation for the next generation of PLM. SMBs gain enterprise-grade capabilities without complexity, and enterprises gain agility and supply chain connectivity at scale.

Multi-tenancy, configurability, and cross-tenant collaboration are not just technical features—they are the pillars of a new way of working in manufacturing. They reduce costs, accelerate adoption, and enable companies to build resilient digital ecosystems.

REGISTER FOR FREE and explore OpenBOM demos and resources to see multi-tenant PLM in action.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.