Dear OpenBOM users. We are starting a new set of videos to demonstrate the fundamental features of OpenBOM. We will be outlining the main OpenBOM capabilities in simple, user-friendly, bite-sized videos and articles.

In this first article, we would like to speak about Items. OpenBOM is an online platform that manages product data and an item is a basic building block that holds an entire foundation of data management in OpenBOM. In a nutshell, OpenBOM manages items. An item can be anything – standard part, material, labor, purchased assembly, and final products.

OpenBOM Catalogs

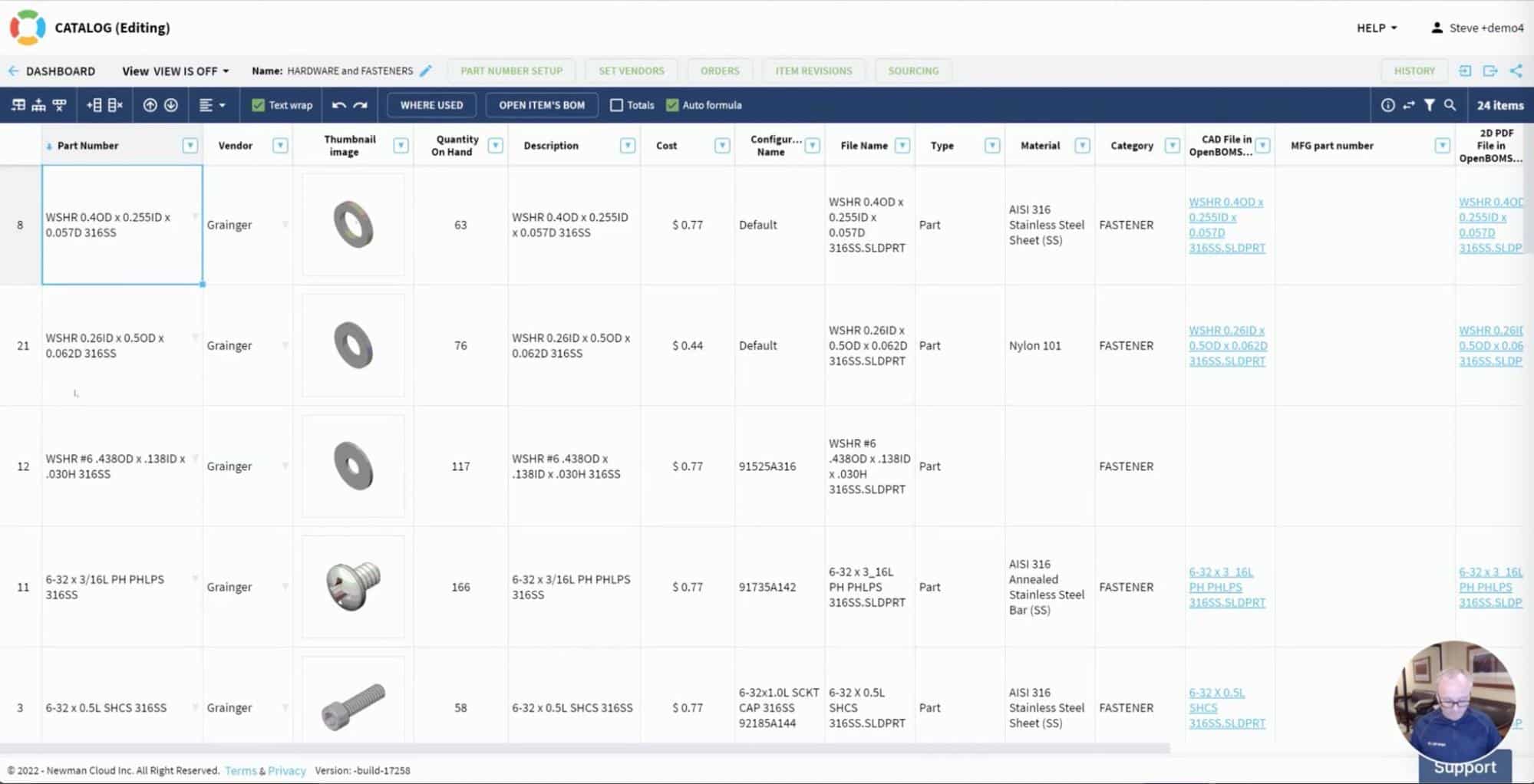

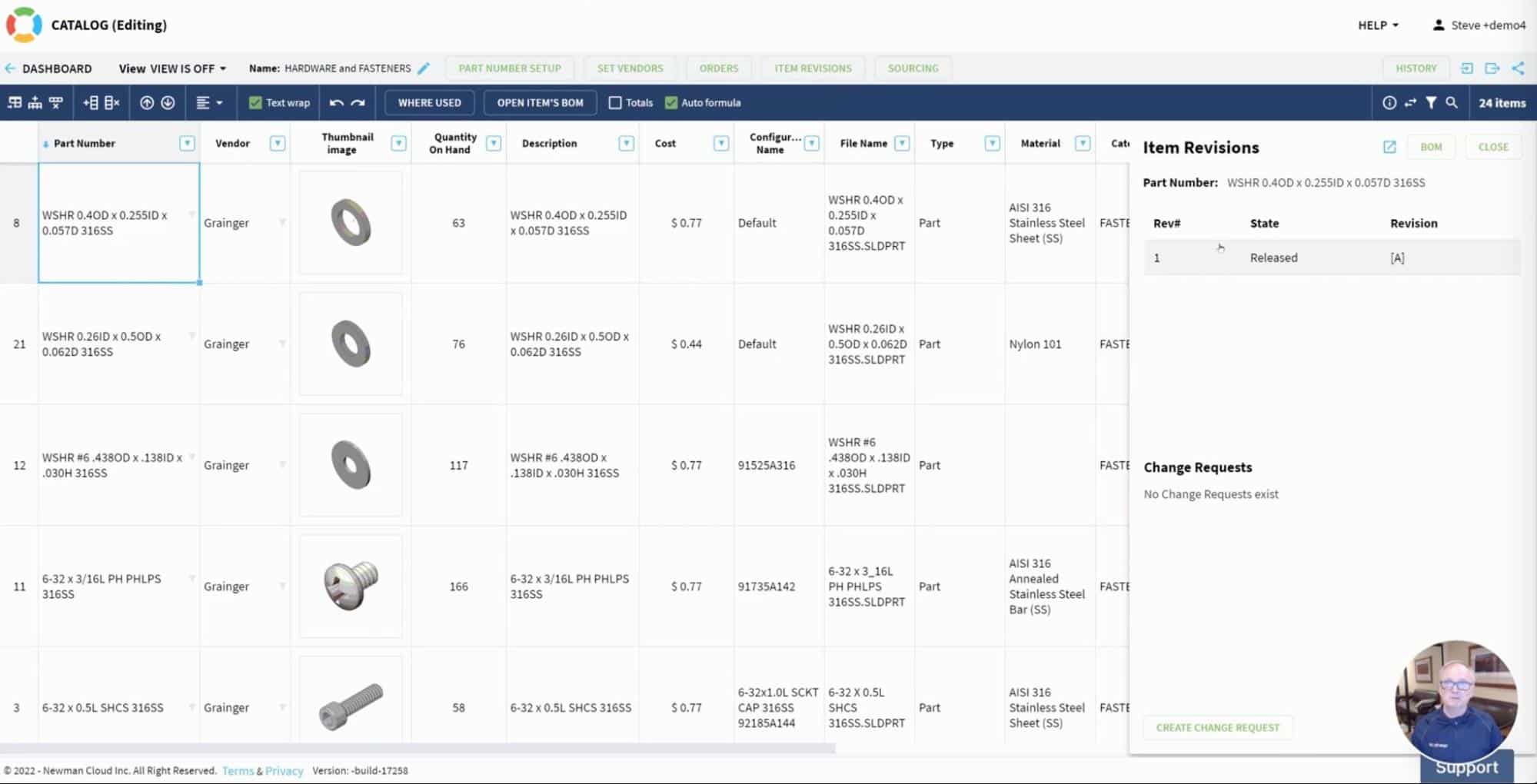

OpenBOM manages items in “databases” called OpenBOM catalogs. You can organize an unlimited number of catalogs in OpenBOM, each one will hold a specific item type with a corresponding set of attributes. Here is an example of the catalog that holds “fasteners”.

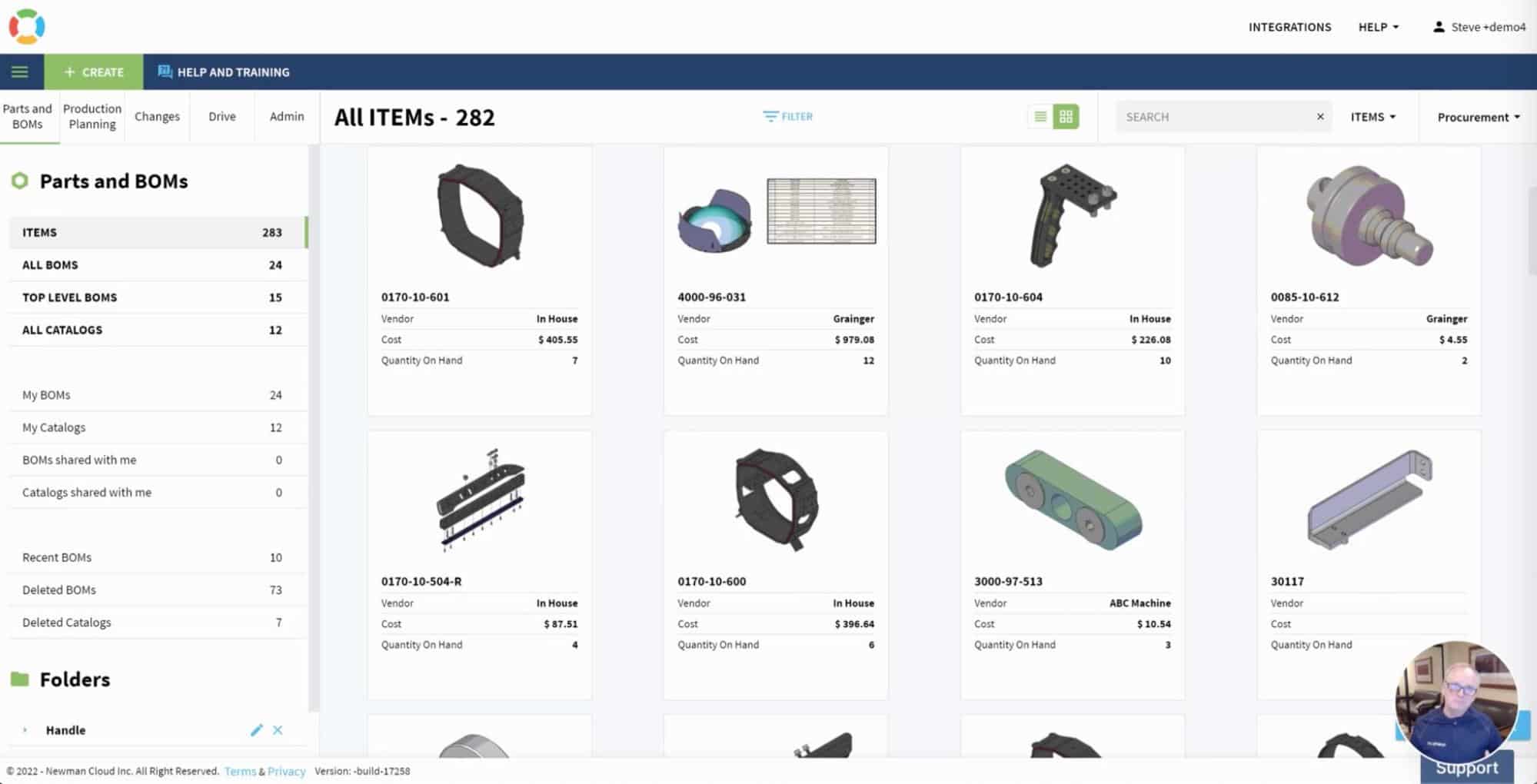

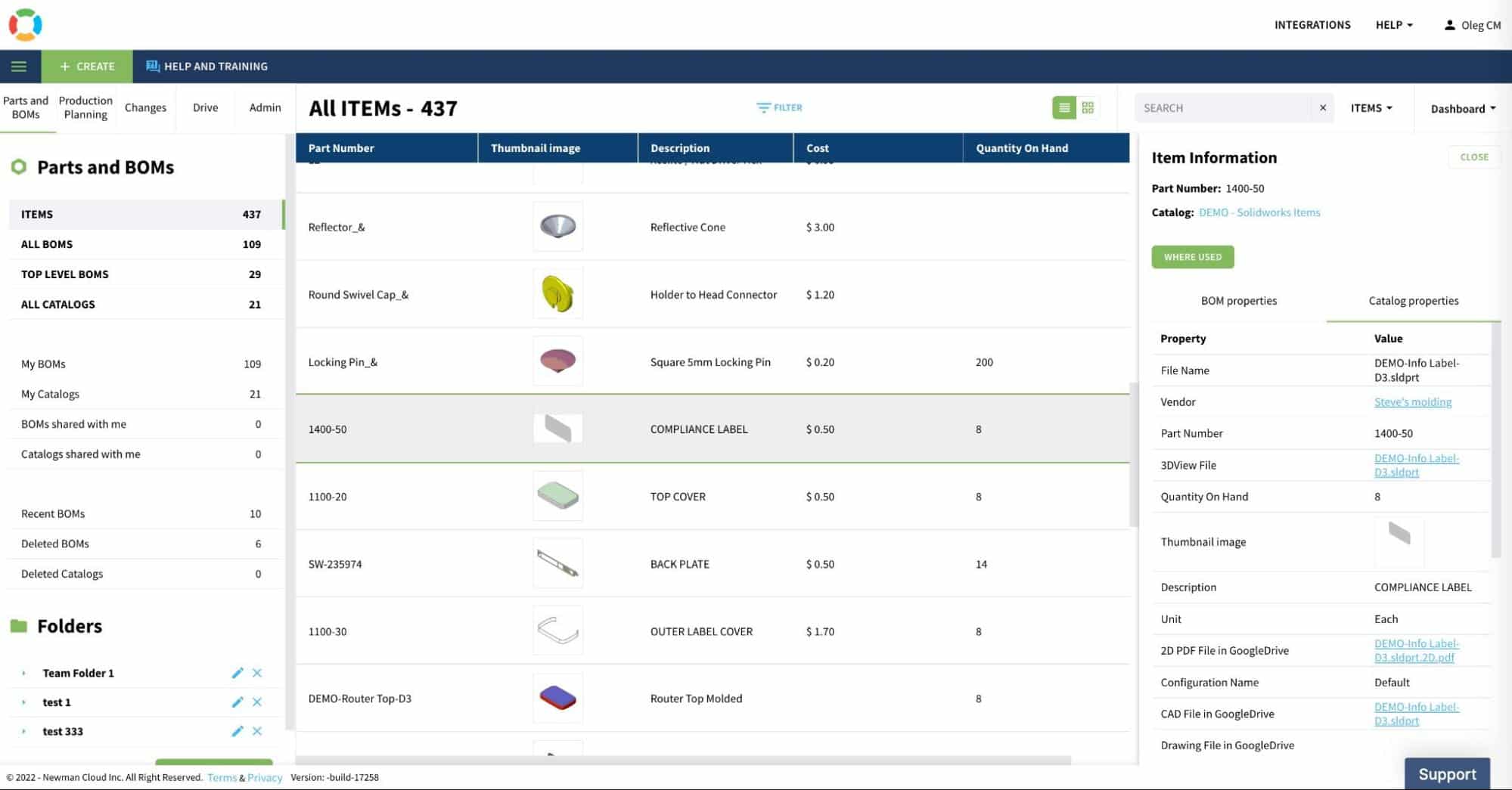

While accessing catalogs can be quite easy, OpenBOM provides an item dashboard that allows you to easily search all items in your account. The initial order of items in the dashboard reflects the items that were most recently updated. You can add filters and search.

The dashboard can have either “tiles” or a “list” views. The set of attributes visible in the dashboard can be configured via a user-defined view.

Item Attributes and File Attachments

OpenBOM allows the definition of any number of attributes to each item. Check OpenBOM documentation for the available types of attributes (properties). Using the “Reference” property you can attach multiple files to an item – eg. CAD documents, Drawings, specs, instructions, etc.

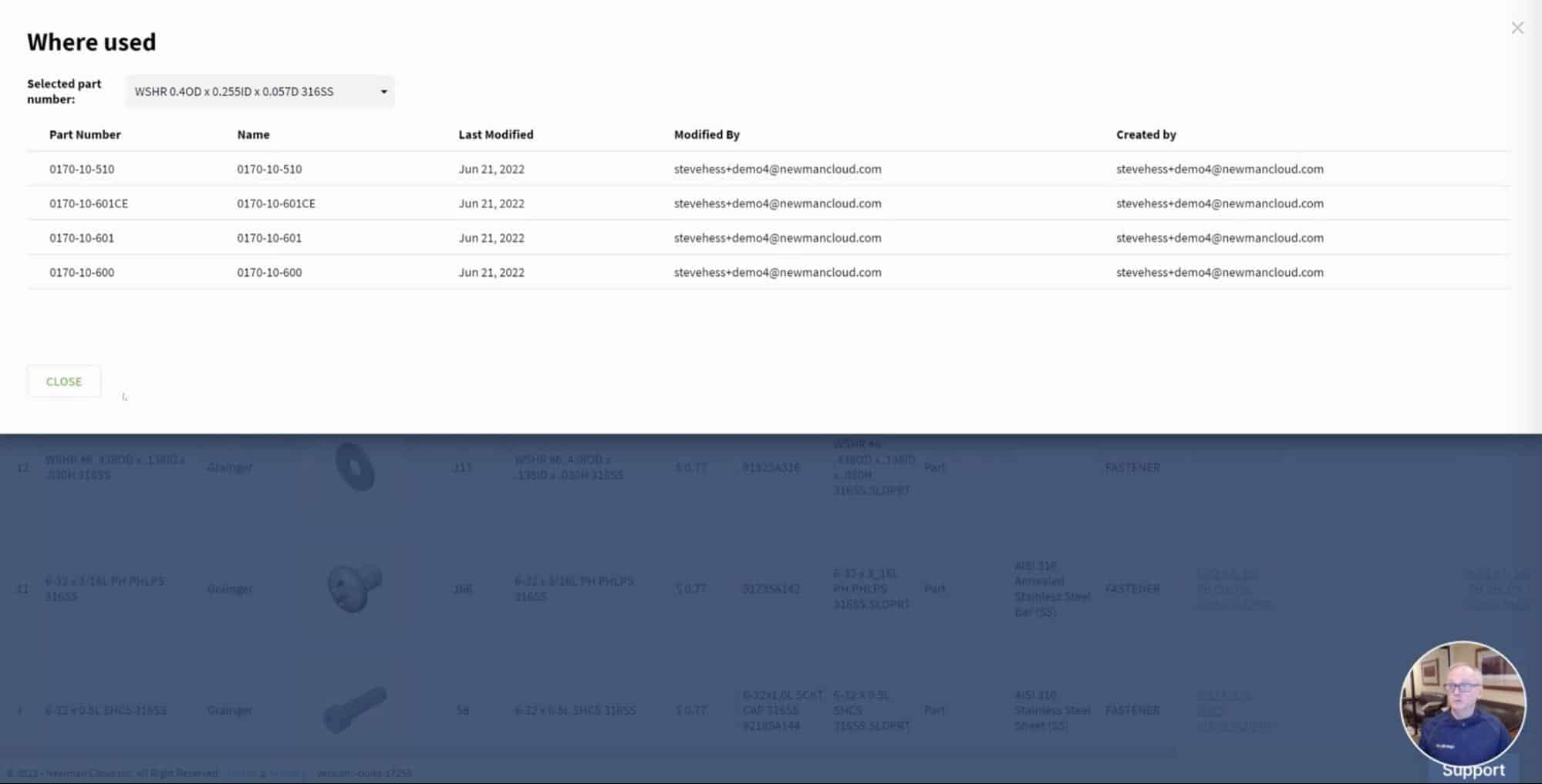

Item – “Where Used”?

OpenBOM maintains traceability of item usage across multiple product structures (bill of materials). You can always get this information using the “where used” command and navigate to a corresponding BOM.

Item Revisions

OpenBOM allows you to manage revisions of items in the catalog. An infinite number of revisions can be created. Each revision has a full immutable copy of all attributes including file attachments.

Demo Video

Please check the video by Steve Hess demonstrating the basics of OpenBOM Items and related functions.

Conclusion

Item is a fundamental OpenBOM data management mechanism that allows you to organize a database of different items, classified by types and organized in catalogs. Each catalog has a part number setup allowing you to define an individual set of attributes (properties), manage revisions, sourcing options (vendors), and capable of holding multiple file attachments. It is a basic product lifecycle management block of the OpenBOM data management platform.

REGISTER FOR FREE to check out how OpenBOM can help you today.

Thank you, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.