Seamless data integration is one of the most demanded features coming from all industries and customer types. No one likes to re-enter data manually which can lead to making mistakes by engineers, purchasing managers, manufacturing planners, and contract manufacturers. I can continue the list. Everyone we are talking to at OpenBOM told us that seamless exchange of information is their first priority.

The ability to automatically extract and exchange data is also the first step into digital transformation – one of the first priorities for all industrial companies as they are looking at how to move away from old-fashioned paperwork and sorting Excel spreadsheets.

Why OpenBOM is Your First Step In Digital Transformation?

A majority of CAD design work is still done using CAD files and desktop design systems. This means information is locked in the desktops and CAD files without the ability to be transferred seamlessly and painlessly to all downstream consumers of the data.

OpenBOM solved the problem of seamless data transfer and exchange between CAD systems and BOM management and purchasing process by providing out of the box CAD add-ins with one-click BOM functionality allowing a single touch data extraction, packing it into online catalogs and BOMs, sharing it instantly with everyone else in the team, company, contractors and suppliers. Check OpenBOM Integration page to download and install OpenBOM CAD Add-ins.

NEW: Selective Bi-Directional Data Exchange

OpenBOM CAD integrations support bi-directional data exchange. Not only can you extract data from the CAD system and bring it to OpenBOM, but you can also send updated information back. Editing data in a simple spreadsheet-like user interface is much easier, therefore many OpenBOM customers are editing data in OpenBOM and sending it back to CAD systems (eg. SOLIDWORKS).

In the recent OpenBOM production update, we introduced a new feature allowing a selective data exchange. In a nutshell, the feature allows you to select a sub-set of properties (attributes) to be transferred back to the CAD system. The feature was first introduced in the SolidWorks add-in, but gradually will be extended to other CAD add-ins.

Demo Video

This improvement gives you complete control over which properties are sent from OpenBOM back to Solidworks.

To use this capability you should be sure you have the latest version of OpenBOM for Solidworks add-in, then:

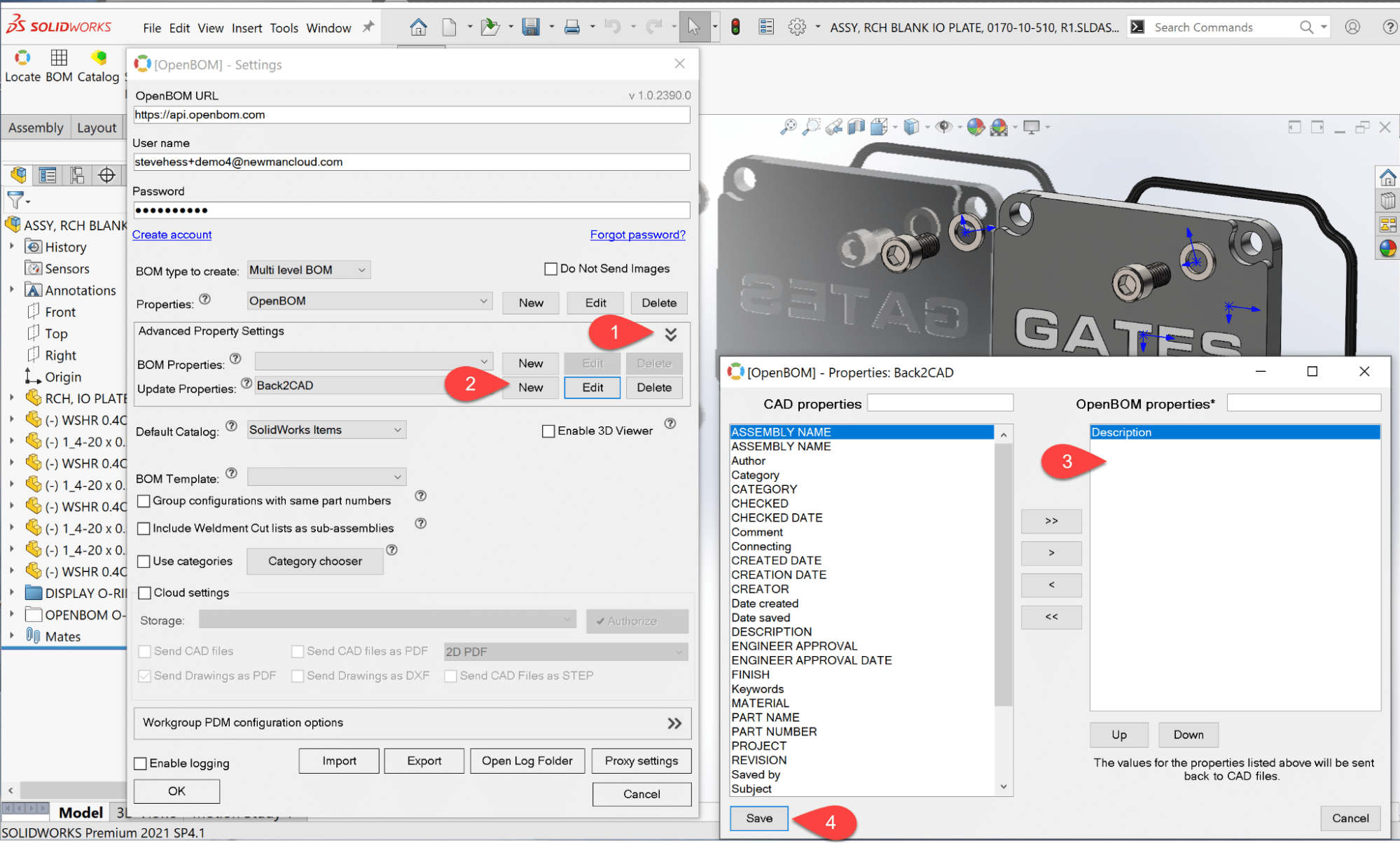

- In the OpenBOM settings click Advanced Properties Settings

- Create an Update Properties list as shown below (Back2CAD in my example)

- Add Only those properties you wish to send BACK to Solidworks (Description in the example below)

- Save the Property list

- Close the Settings

- Open your Solidworks Assembly

- Click the Update CAD Properties command

- Select the BOM to get the values FROM

- Optionally choose to create the properties in your Solidworks files if they do not exist. Only these property values will be sent FROM OpenBOM to Solidworks.

Conclusion

Seamless information exchange is a key element of a successful data management strategy. In the world of engineering systems, it is extremely important to be able to exchange data (extract and save it back) with CAD systems, which is usually a core element of the design and data creation process. OpenBOM gives you out-of-the-box capabilities to seamlessly integrate with CAD systems and define what data is extracted from CAD systems, transferred to the cloud (including all properties and files), and then, later on, can be synchronized back with CAD systems. We made a new process of selecting data exchange between CAD and OpenBOM allowing you to define a granular list of what properties will be updated in both directions.

REGISTER FOR FREE and check out how OpenBOM can help you today.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.