In this article, I’d like to share a basic introduction to the OpenBOM business process streamlining the data and business handover from design to purchasing and inventory management. The basic elements of the OpenBOM business process are covering the following

- Managing and exploring the Bill of Materials

- Managing Vendors

- Integration with CAD systems

- Managing Orders and Order BOM

- Creating of Purchase Orders

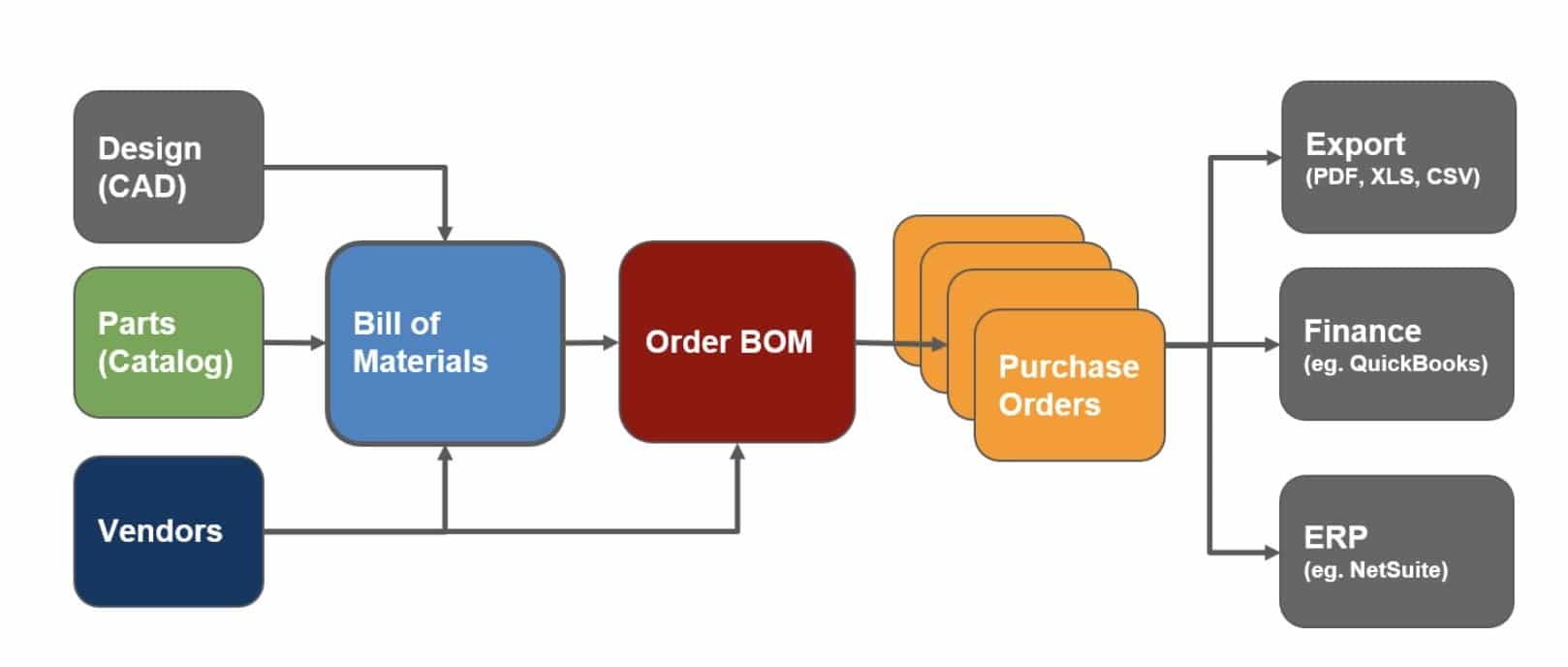

The following picture describes the steps of OpenBOM supported business process. It starts from the organization of catalogs – a single version of the truth, creation of BOMs (either manually or from CAD systems), and management of vendors.

Bill of Materials is a centerpiece of product structure data representation that allows organizing information about products and all related information.

Planning activities are organized using an Order BOM. The inventory information is managed in the catalogs in the way of Quantity on Hand (QOH), vendors, and preferred vendors signs.

Watch the video that gives you a high-level review of working in OpenBOM and its user experience.

Conclusion

OpenBOM helps you to manage Parts, Vendors, Bill of Materials, Planning, and Ordering of Parts. OpenBOM is combining a well-known spreadsheet paradigm and unique real-time collaboration and simultaneous editing, using cloud/SaaS architecture and subscription business model to simplify product development, procurement, and connect engineers and manufacturing with their contractors and supply chain partners.

Check OpenBOM today by registering for a FREE user subscription today.

Best, Oleg @ openbom dot com.

Want to learn more about PLM? Check out my Beyond PLM blog and PLM Book website. Read OpenBOM customer reviews on G2 Crowd to learn what customers are saying about OpenBOM.

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.