Have you ever faced that moment during a project review where someone asks, “Why did the cost go up?” or “What changed between these revisions?” It’s a common and often stressful situation—especially when you’re juggling design updates, supplier negotiations, and looming deadlines.

At OpenBOM, we believe that cost tracking should be effortless, transparent, and part of your natural workflow. That’s why we’ve built powerful capabilities to help you track and compare the cost of your BOMs across multiple revisions.

Let’s talk about how it works—and why it matters.

A Clear History of Changes—With Cost Included

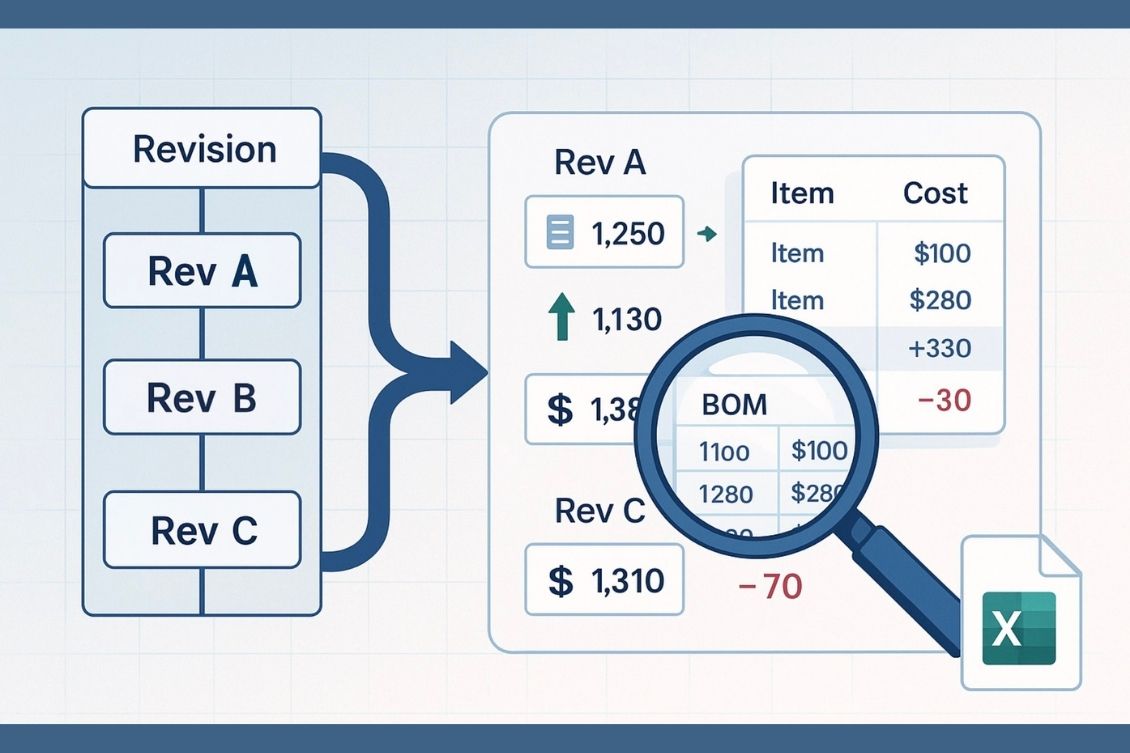

Every time you create a revision in OpenBOM, the system captures not just the structural snapshot of your BOM but also the full cost context. That includes the unit cost of each item, any calculated values (such as extended or rolled-up cost), and the total BOM cost at that point in time.

This means you’re not just tracking what changed—you’re seeing how those changes affected your bottom line. Whether it’s a minor component swap or a full assembly update, OpenBOM keeps the full story intact, including its financial impact.

Cost Comparison That Makes Sense

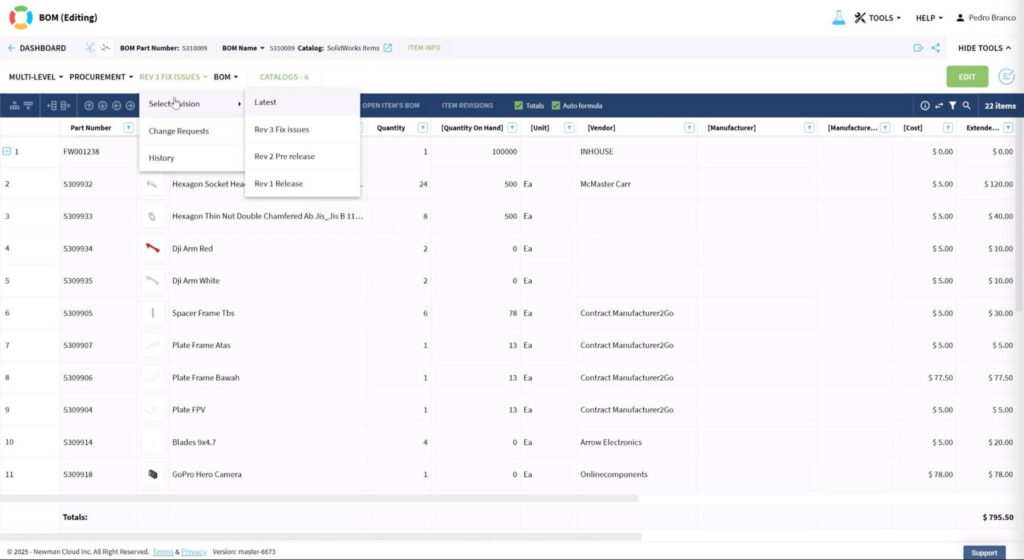

Navigating between revisions is easy. You can open any previous version of your BOM and instantly see the cost breakdown as it stood at that moment. But the real power comes when you use OpenBOM’s Compare feature.

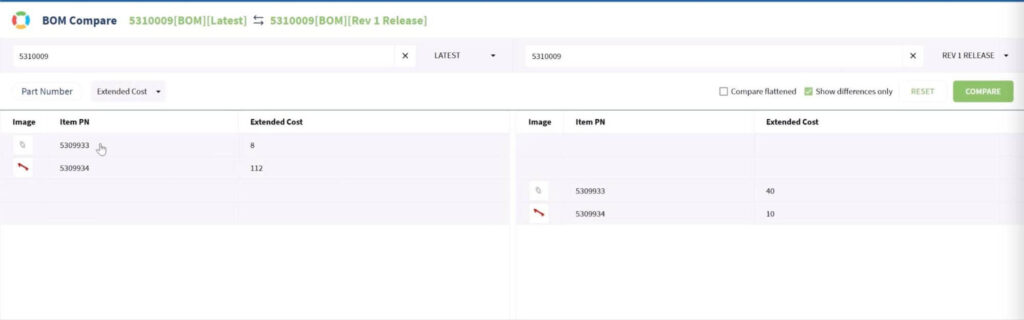

With a simple click, you can compare two revisions side-by-side and instantly spot the differences—both in structure and cost. Did someone change the part? Was a cheaper or more expensive component used? Did a supplier update their price?

Instead of digging through spreadsheets or emailing for updates, you get immediate answers.

Ready to Share or Export

We also know that sometimes you need to take this information outside of OpenBOM. That’s why exports to Excel are seamless—keeping all the cost, structure, and revision details intact. So, whether you’re preparing a report, doing a financial review, or integrating with another system, the data is always ready to go.

Watch the Demo: Comparing BOM Costs with OpenBOM

To show you how all this works in practice, we’ve prepared a short video demo. You’ll see how easy it is to save revisions, navigate historical cost data, compare BOMs, and identify exactly where and how the costs have changed.

In just a few minutes, you’ll see how OpenBOM gives you the insight you need to stay ahead of cost surprises and keep your team aligned.

Conclusion and Why This Matters

Cost tracking across revisions isn’t just about accounting—it’s a critical enabler for collaboration. When engineers and procurement teams can both see the same cost history, it’s easier to make confident decisions, avoid misunderstandings, and move forward faster.

Instead of reacting to cost increases after the fact, you get early visibility into changes—when there’s still time to adjust. That’s how modern teams work smarter.

If you’re not already using OpenBOM, now’s a great time to explore it.

👉 Register for free and discover how easy and valuable it is to track cost differences between revisions—and keep your projects on budget and on track.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.