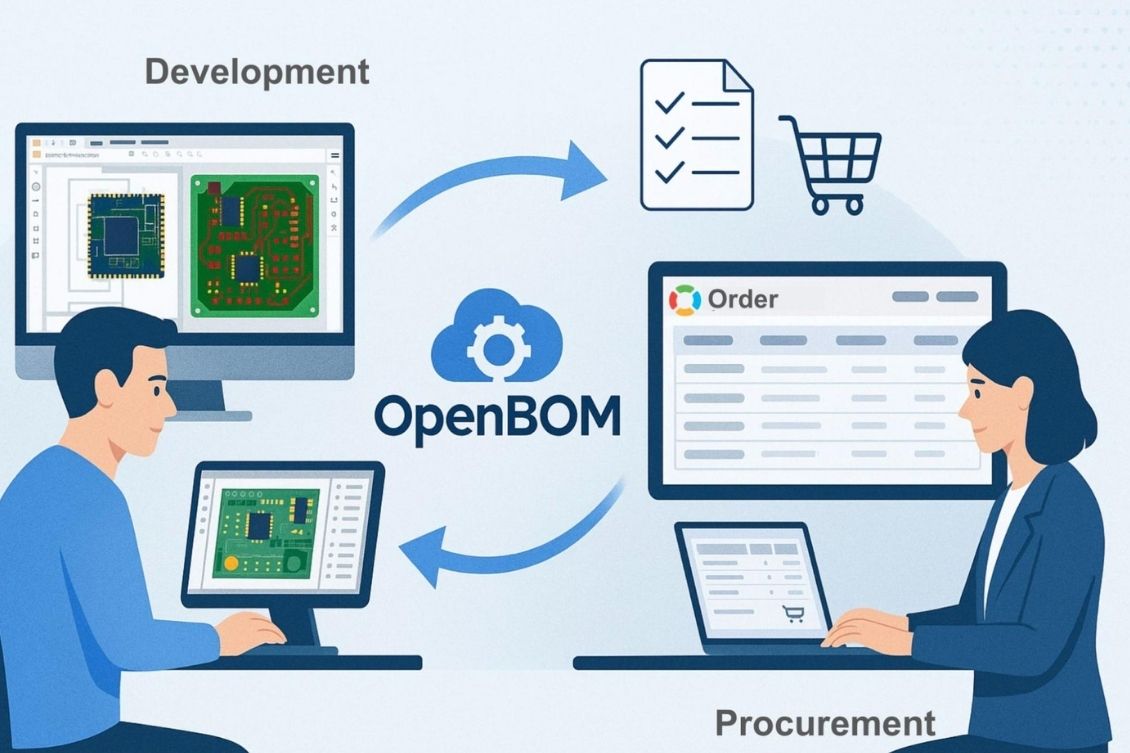

Engineering and procurement are two operations that often run in silos even in a small organization or engineering team. Their nature is to focus on different goals – best design and optimized supply chain. At the same time, every team and organization I talked to desires to make them connected, to allow engineers and purchasing to seamlessly work together.

In an ugly Excel world, once an engineer “released” a BOM spreadsheet to a procurement, the updates will remove procurement team comments and vice versa. So, they are stuck in inefficient updates. The gap between engineering and procurement often becomes a costly bottleneck. Missing parts, outdated spreadsheets, and delayed component orders can derail even the best-designed product.

At OpenBOM, we believe the key to solving this challenge lies in seamless integration between design tools and procurement workflows. The foundation of this process is Digital BOM with real-time seamless collaboration, CAD add-ins, and Inventory planning functions.

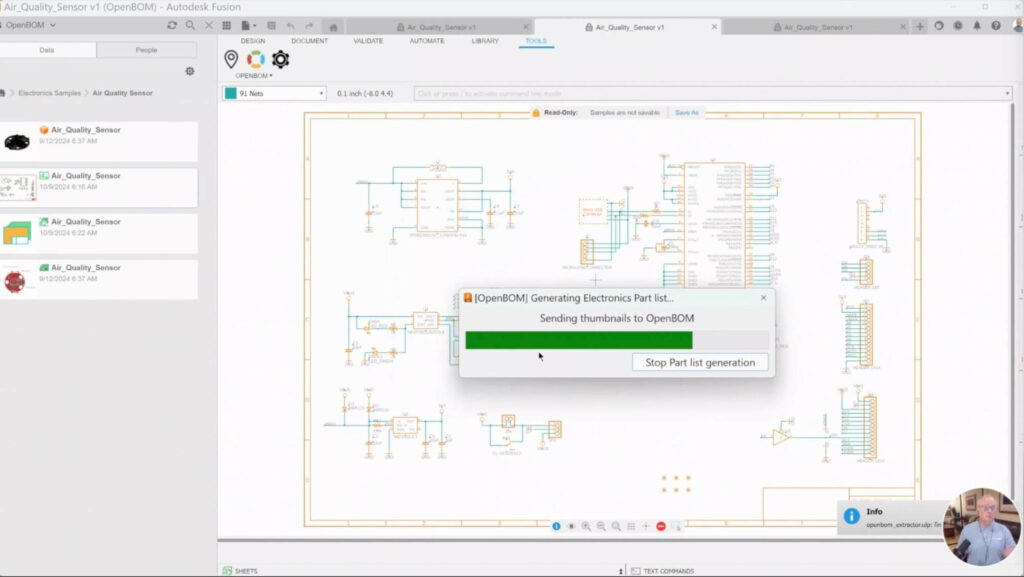

In my article today, I’m excited to introduce the updated OpenBOM Add-in for Autodesk Fusion Electronics — a direct bridge between your PCB design and the real-time procurement process.

Let’s explore how this integration improves your electronics design workflow and brings traceability and agility to your ordering process.

Why Engineering-to-Procurement Integration Matters

Traditionally, engineering and procurement operate in silos. Design teams work in CAD tools, and procurement teams juggle spreadsheets, PDFs, and emails to place orders. This fragmented approach is prone to errors and inefficiencies.

When engineering and procurement are natively integrated, organizations can:

- Accelerate time-to-prototype: Instantly translate design intent into a purchase-ready BOM.

- Avoid delays and rework: Eliminate manual transcription errors and out-of-sync part information.

- Align engineering and supply chain teams: Everyone sees the same up-to-date data, enabling better collaboration and decision-making.

This integration becomes even more critical when building small batches (e.g., five PCBs), where any delay or missing part can halt progress.

OpenBOM + Fusion Electronics: A Seamless Workflow

The updated OpenBOM Add-in for Autodesk Fusion Electronics creates a smooth, connected experience between your design and procurement process. Here’s how it works:

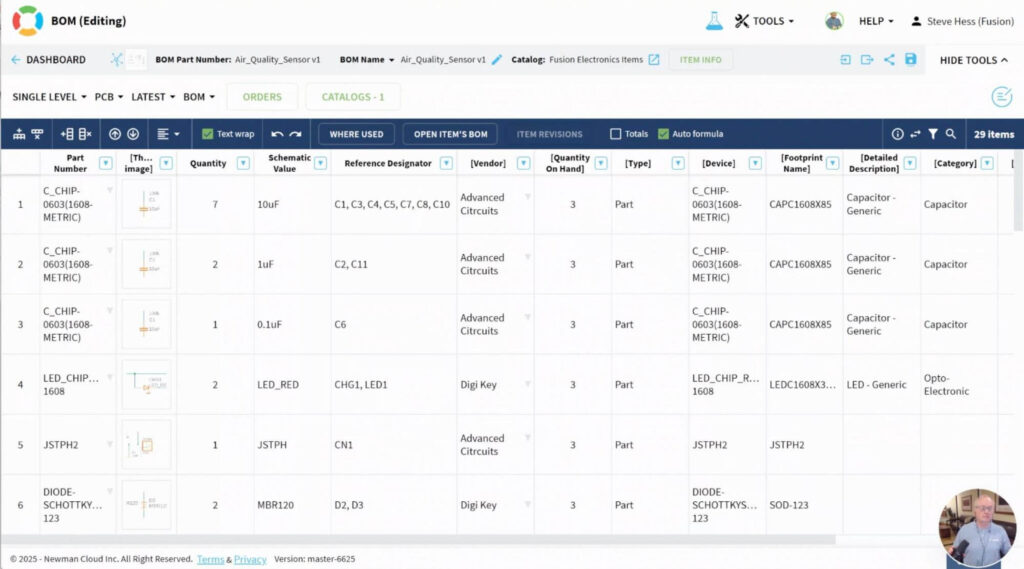

- Push BOM directly from Fusion Electronics to OpenBOM: Automatically extract part information, including design parameters, reference designators, and descriptions.

- Enrich BOM with purchasing data: Add supplier part numbers, costs, and preferred vendors — either manually or through integration with online part catalogs.

- Collaborate across teams: Share your BOM securely in the cloud with purchasing, production, or external contractors — no email chains or file attachments required.

Whether you’re building a prototype or preparing for production, this integration ensures your BOM is always accurate, up-to-date, and actionable.

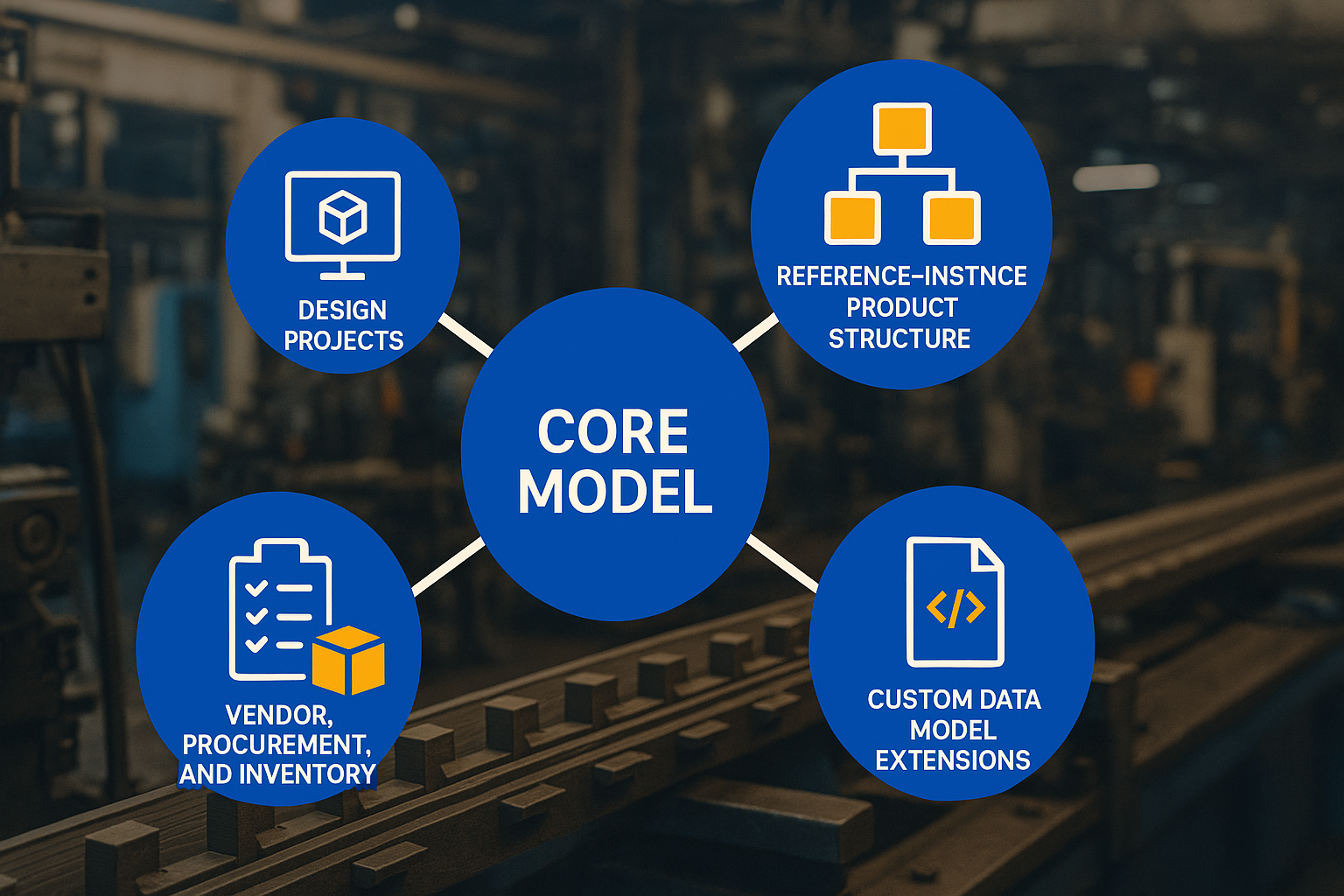

Digital BOM: The Backbone of Modern Connected Process

A Digital BOM is not your grandfather’s spreadsheet – it’s a living, structured record of everything needed to turn your design into a physical product. OpenBOM brings collaboration and intelligence to this core asset.

Benefits of OpenBOM’s Digital BOM model:

- Full traceability: Track changes and revisions to BOMs over time.

- Multi-view support: See engineering, purchasing, or manufacturing views based on your role.

- Real-time updates: As designs evolve, BOMs stay current — reducing the risk of ordering incorrect or outdated parts.

This structured data foundation makes it possible to automate procurement processes, perform analysis, and support growth without increasing complexity.

Inventory, Gap Analysis, and Ordering – Unified in OpenBOM

Once your BOM is ready in OpenBOM, the platform takes it a step further by helping you plan procurement intelligently.

OpenBOM enables:

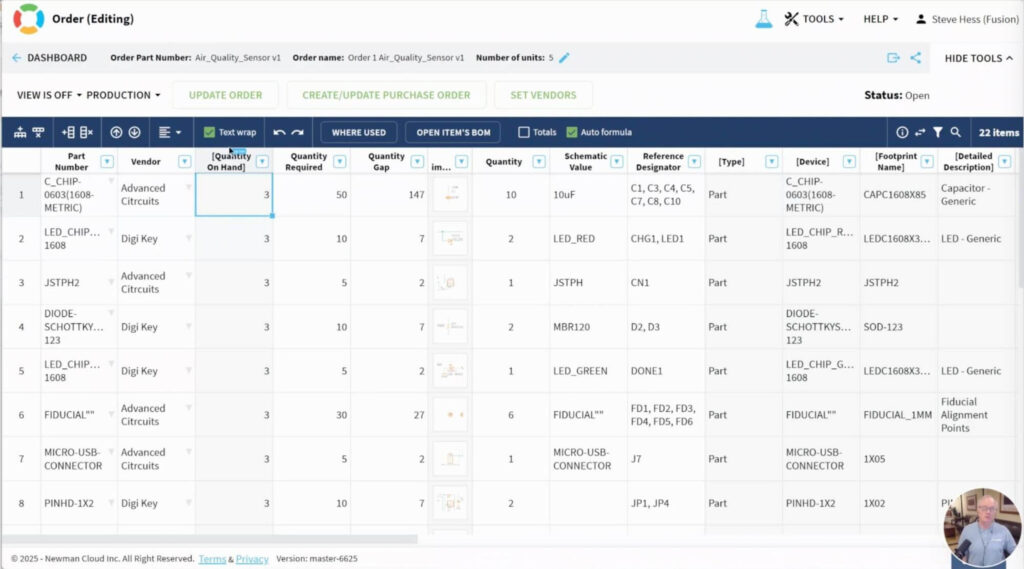

- Inventory Check: Instantly see which components you already have and how many units can be built with current stock.

- Gap Analysis: Automatically calculate shortages and what’s needed to complete a build (e.g., five PCBs).

- Order Planning: Generate purchase orders or order plans based on selected vendors, pricing, and lead times.

- Vendor Collaboration: Share orders with suppliers or generate downloadable reports for your procurement process.

This integrated capability means fewer surprises and smoother execution, especially for time-sensitive prototype builds.

The ROI: Speed, Accuracy, and Connected Teams

By connecting Autodesk Fusion Electronics and OpenBOM, you unlock a more agile and scalable development process.

Here’s what you gain:

✅ Faster product cycles. Push BOMs and generate order plans in minutes — not hours or days.

✅ Fewer errors and rework. Stop manually copying data from CAD to Excel to procurement tools — it’s all synced.

✅ Live collaboration across functions. Keep engineers, buyers, and managers on the same page — even if they’re in different locations.

✅ End-to-end traceability. Know exactly which design led to which order, with full revision history and audit trails.

✅ Scalability without chaos. Start with five PCBs, scale to production, and keep your process clean, connected, and reliable.

The result? A more confident, traceable, and cost-effective way to move from electronics design to physical product.

📽️ Watch the Demo

See the integration in action. This short demo video walks you through:

- Connecting Fusion Electronics to OpenBOM

- Generating a PCB BOM from your design

- Performing inventory gap analysis

- Creating a procurement order in just a few clicks

👉 Watch the Demo Video

Conclusion:

Designing PCBs is only half the challenge — getting them built on time with the right components is just as critical. With the updated OpenBOM Add-in for Fusion Electronics, you can close the gap between design and procurement.

Whether you’re prototyping a new board or moving toward scaled production, OpenBOM helps you reduce risk, increase traceability, and accelerate time to value.

Try the new integration today and streamline your entire PCB workflow.

REGISTER FOR FREE to check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.