Every engineering team has lived through this moment: a new product revision gets released, the buyer runs a PO, and something doesn’t match. A part was added, a quantity changed, or a reference designator slipped — and no one noticed. Until now.

That’s where OpenBOM’s BOM Compare service steps in. It’s not just about seeing what changed — it’s about building trust in your process. Whether you’re working through a design review, a cost analysis, or just trying to keep engineering and procurement in sync, BOM Compare gives you clarity, fast.

Let me walk you through how it works, how teams are using it, and what’s coming next.

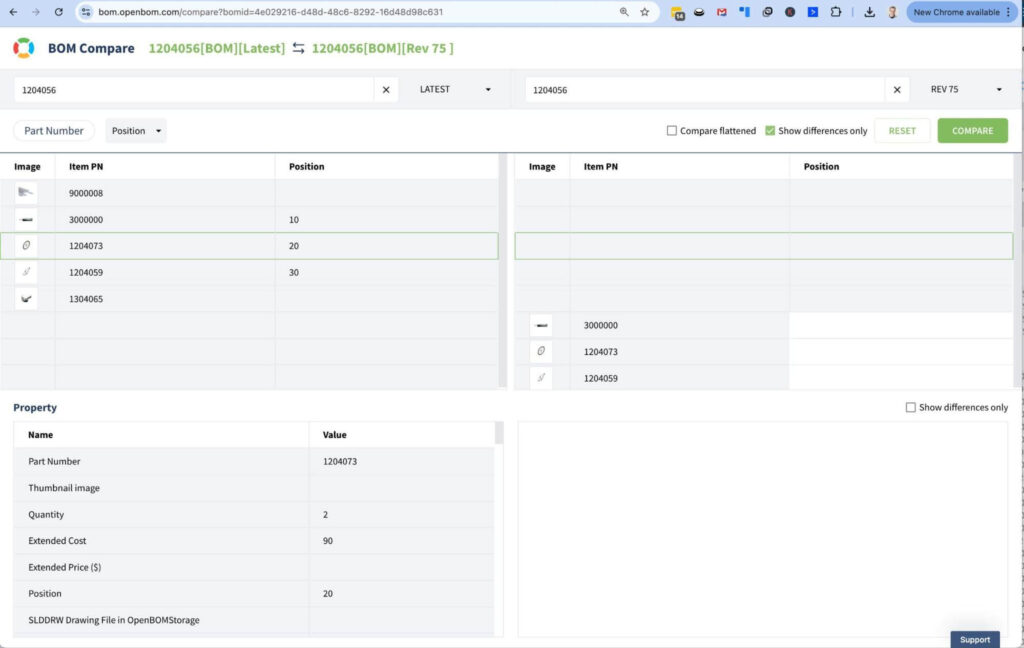

A Simple Start: Comparing BOMs by Line and Part Number

Let’s start with the basics. Imagine you’re an engineer reviewing two revisions of a mechanical assembly. You load them into OpenBOM and click “BOM Compare.” Right away, you see what was added, what was removed, and what stayed the same — all lined up by Part Number.

One of our customers calls this the “sanity check before release.” It gives them a fast way to scan and confirm that no part went missing during the revision process. That bolt that changes the quantity from 1 to 4? You’ll see it. That new bracket someone added last-minute? It’s clearly marked.

And because the comparison is done by line and Part Number, it’s perfect for quick flat-BOM use cases — electronics kits, packaging parts, or short-run assemblies. But the real power of OpenBOM Compare shows up when changes go deeper.

Seeing Beyond the Surface: Advanced Property Comparisons

Let’s say the parts are the same — but something changed under the hood. Maybe the description changed or the reference designators were updated from “R1, R2” to “R1, R3.” Maybe a supplier name changed, or the cost was updated after a new quote.

In traditional systems, these changes often fly under the radar. You’d have to go property by property, scanning cell by cell.

With OpenBOM’s advanced comparison, that’s all automatic.

One customer shared a great story: they were preparing a final release and ran a comparison just to be sure. They expected no changes. But the system flagged a small update — a capacitor’s value had changed slightly, and the quantity was off by one. That one change would have triggered a manufacturing issue and delayed their pilot build. But thanks to BOM Compare, it didn’t.

What’s great here is that you can specify exactly which properties to compare. So if you’re focused on cost, OpenBOM shows you the cost differences. If it’s reference designators or vendors, those become the focus. You stay in control.

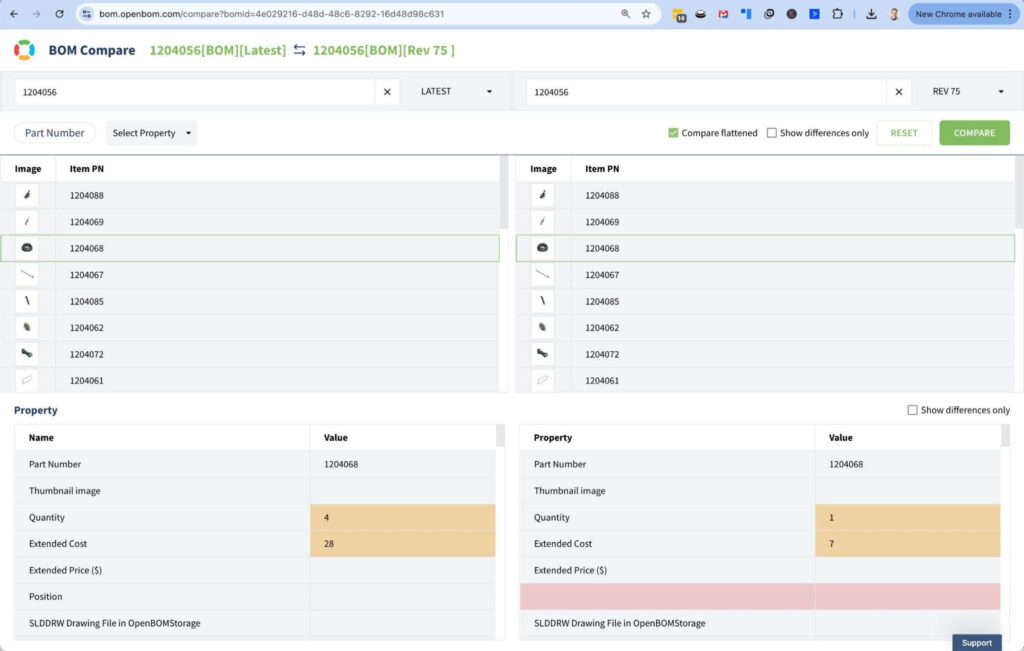

For Complex Products: Flatten and Compare Across Structures

Things get more interesting when you’re working with a complex, multi-level product. You may have assemblies with subassemblies three or four levels deep. A battery pack might appear in multiple places, or a sensor might be nested inside a mechanical enclosure.

In cases like these, OpenBOM offers a Flattened Compare view. It’s like rolling up the entire hierarchy into one single structure, so you can see total quantities and changes across the full product — not just at the top level.

A robotics team we work with uses this feature every time they move from prototype to production. They need to know how many screws, sensors, and brackets they’ll need — not just in each subassembly, but across the whole robot. When the team made a design tweak that removed a part from one subassembly but added it to another, the flattened compare caught the shift. The net quantity changed, even though the part never disappeared.

This kind of insight is critical when you’re planning purchases or working across distributed teams.

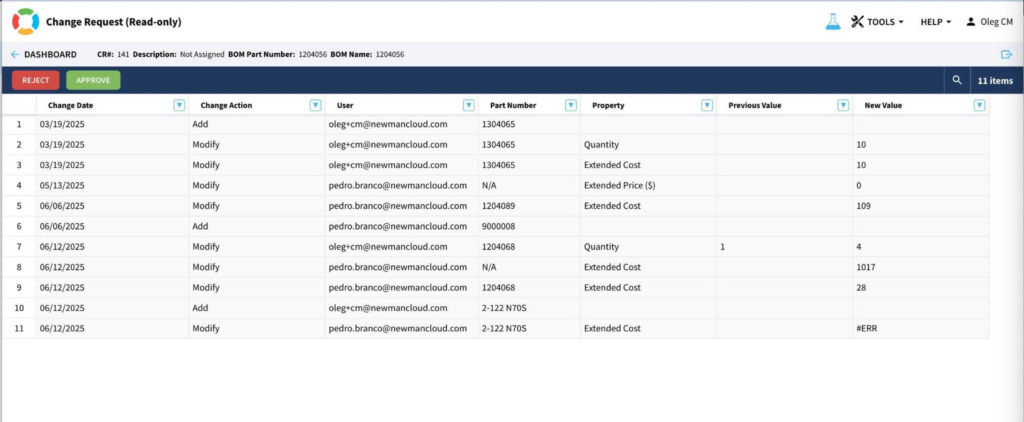

Change Report using OpenBOM Change Request (CR)

Another very efficient way to make comparisons is to use the OpenBOM CR function. It creates a report about what changed in the collaborative workspace (“Latest”) compared to the last revision saved.

This report can be exported to Excel and used for recording and reporting to the shopfloor, contractors, and suppliers.

What’s Coming Soon?

We’ve been listening closely to how customers use BOM Compare — and what they’d like to do next.

One highly anticipated enhancement is the ability to export a summary of the differences. Soon, you’ll be able to download a structured report showing what changed, where, and how — perfect for design reviews, compliance documentation, or vendor communication.

Another upcoming improvement is smarter visual highlights. Today, differences are clearly shown — but we’re making them even easier to spot, especially when changes span across large BOMs or involve long property names. Think of it as “highlight what matters most,” tailored to your workflow.

Conclusion

At the end of the day, BOM Compare is more than a tool — it’s peace of mind. Combined with the CR (change request) reporting, it gives the confidence that what you see is what’s really there, that the changes are traceable, and that you’re not going to miss something important.

Whether you’re reviewing a single design change or validating a full production release, OpenBOM Compare puts the control in your hands. You can compare by line, by property, across flattened structures — and soon, export everything with full clarity.

Want to experience BOM Compare yourself? OpenBOM is free to test. It only takes 30 seconds to create an account.

Register for free and check how you can use OpenBOM to navigate product data changes.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.