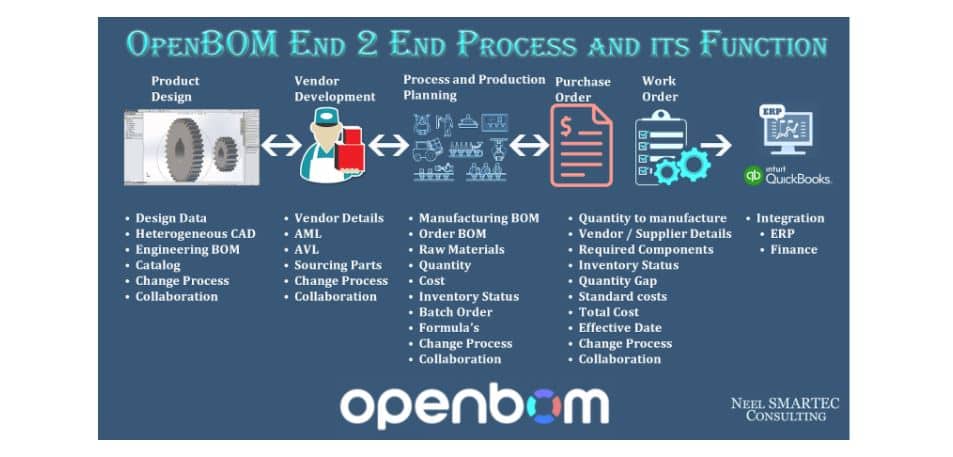

Last year, we introduced Neal SMARTEC consulting. Check out our article to learn more. We’ve been excited to hear about SMARTEC approach to solve problems of small and medium size companies. Here is how SMARTEC defines the major challenges.

Major Challenge of SME: The primary challenge that any type of manufacturing business experiences is the adequate number of finished items in hand, but unable to offer them as a result of their much less demand in the market. One solution to curb the above situation is to manufacture the product according to demand. But there occurs an additional issue with resources or component products. The raw materials when kept for a very long time usually shed their quality and also obtain damage. In either of the above scenarios, the ultimate outcome is the damage of the items as well as their big loss. The efficient functioning of a manufacturing business can be accomplished by producing the items just after the development of a sales order. This enables manufacturers to acquire the called for quantity of raw materials which leads to less wastage, enhanced high quality and enhanced profit.

We are excited to bring a story of Nandan GSE. Nandan GSE delivers bespoke made-to-order innovative Aviation GSE manufacturing & Hydraulic Lifting System products on time and on budget using a variety of design tools relying on OpenBOM to bring them all together for the customer.

Nandan GSE delivers bespoke made-to-order innovative Aviation GSE manufacturing & Hydraulic Lifting System products on time and on budget using a variety of design tools relying on OpenBOM to bring them all together for the customer.

The team at Nandan GSE collects customer requirements and design parameters then produces a variety of design options to present to the customer, eventually selecting the best alternative in concert with the customer. The entire process is data-driven and a full understanding of the bill of materials is mandatory – at all phases of the process.

“Working through our OpenBOM certified consultant Neel SMARTEC we implemented OpenBOM in significantly less time than conventional PLM,” says Nadan GSE CEO Raghunandan Jagdish, “as such, we brought a level of organization to our build process which our customers were demanding. It was a win-win.”

Conclusion

We are excited to see how new PLM implementation processes can help manufacturers in this modern environment.

New SaaS technologies and agile PLM implementation are helping companies transform their operations to more modern and efficient model.

Register for FREE to use OpenBOM today to change the way you work and stop using messy Excels. If you have any questions feel free to reach out!

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.