At OpenBOM, we make engineering data accessible to business functions—procurement planning, supply chain management, cost estimation, and more.But to make that possible, you first need to turn your design into a foundation for real planning.

We’ve seen many customers get stuck in the process simply because they weren’t prepared. You’ve got a beautifully designed CAD assembly. The design looks solid, everything fits together nicely, and it’s ready to start procurement planning, production work, estimate cost, and focus on how to turn this design into a real product.

But here’s the uncomfortable truth: Can it actually be used to estimate cost, plan procurement, or generate a purchase order?

Spoiler: Not always.

Let me share a real story.

A user contacted our support team recently, excited to explore how OpenBOM could help streamline their information flow — from initial design to costing, procurement, and planning. They had a complete design in hand and wanted to move fast.

But after some digging, we realized something wasn’t right.

The CAD model looked great on the surface, but once we started pulling data, it was clear the foundation was shaky. Many components had no metadata at all. Part Numbers were missing or duplicated (we saw a few “Part Number 1” entries making multiple appearances). Some “configurations” were actual design variants, while others just defined geometrical placements — but all were treated equally.

When I asked the user why the data was in this state, the answer was blunt:

“If my CAD system can handle it, why can’t OpenBOM?”

Well, let’s talk about that.

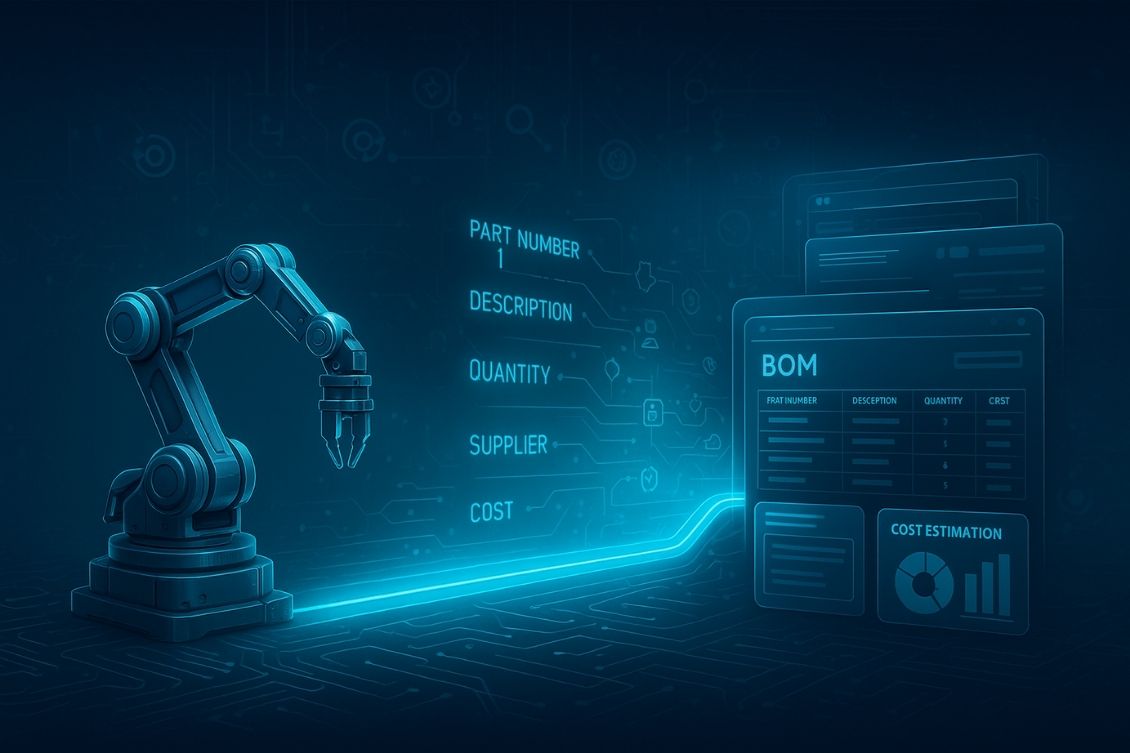

What Does “BOMable” Even Mean?

Over the years, working with many OpenBOM customers, we’ve come to define something we call a “BOMable” design.

BOMable means that your data can be easily translated from a CAD model into a structured, usable Bill of Materials — including part numbers, descriptions, materials, quantities, supplier info, and more.

It’s more than just exporting a parts list. It’s about enabling the next stage of the product lifecycle: ordering, costing, inventory, assembly instructions, and eventually — customer delivery.

And when your CAD data isn’t BOMable?

You hit a wall. Your design becomes a bottleneck, not a bridge.

5 Questions to Assess Your CAD Data’s BOMability

If you’re wondering whether your CAD design is ready for prime time, here’s a quick self-check:

- Do your parts have meaningful part numbers?

Or are you relying on filenames, temporary labels, or repeated values? - Is metadata complete and structured?

Things like descriptions, materials, suppliers — not just floating text or random fields. - Can you clearly separate what’s purchased from what’s made in-house?

Procurement planning depends on this. - Is your assembly structure aligned with how you actually build the product?

Design structures often don’t match real-world manufacturing. - Can you distinguish real components from geometry-only configurations?

Not every instance in your CAD should become a line in a BOM.

If you’re answering “not really” to most of these — your data may not be BOMable just yet.

Common Pitfalls (We See These A Lot)

Let’s take a quick detour into familiar territory — things we see across engineering teams, large and small:

- CAD parts with no material or cost info

- Assemblies packed with placeholders or reference geometry

- Properties that are inconsistent or missing entirely

- Designs that “work” in CAD but fail to carry meaning downstream

The result? Confusion. Delays. Manual rework. And worse, decisions made on incomplete or misleading data.

How to Make Your CAD Data BOMable

The good news is – it’s fixable. And you don’t need to overhaul your entire design process to get started. The core element is to work collaboratively – engineers, procurement team, production planners to improve the data foundation.

Here are a few proven steps:

- Establish a clear Part Numbering convention from day one

- Define standard metadata templates early in your design tools (material, supplier, cost, etc.)

- Use classification tags to differentiate purchased, made, and standard parts, introduce them early and define rules what objects will be captured and what are not

- Connect to a centralized item catalog to unify data across assemblies

- Don’t isolate your CAD — link it to other tools:

from CAD → to EBOM → to sourcing → to purchase orders

This is where OpenBOM really shines – it enables connected data flow, not isolated exports and allows to team members to work collaboratively across multiple roles and departments boundaries.

Why BOMable Data Matters (Especially for AI)

In today’s world, AI is everywhere — including in engineering and manufacturing. So, we need to address it and it actually very important.

But here’s the catch: AI is only as good as the data you give it.

If your CAD model lacks data elements and additional links and description, it can be efficiently used by many AI tools that are growing to support engineers and manufacturers. Those are tasks that BOM product knowledge graph can perform that are becoming a foundation of manufacturing graph.

- Suggest alternative suppliers

- Roll up part costs

- Flag changes across revisions

- Trace components across multiple lifecycle stages

Check out my recent article on Knowledge Graphs to understand why structured, connected data is the prerequisite for intelligent systems.

Conclusion: Don’t Let Your CAD Be a Dead End

CAD is just the beginning. It’s the digital representation of your intent — but that’s not enough.

If your design isn’t BOMable, it can’t move forward into manufacturing, purchasing, or even proper documentation without pain.

So, here’s the question:

Is your CAD data really ready for what comes next?

If not, now’s the time to fix it.

Let us know if you’d like to see how OpenBOM can help you build a truly BOMable design process — one that bridges the gap between engineering and everything that follows.

REGISTER FOR FREE and check how OpenBOM can help you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.