You have evaluated a few different contract manufacturers (CMs) and you have finally decided which CM to proceed with. This is an exciting but also nervous time.

The next step is to organize the documents and data you need to send to your CM. But, what kind of data do you need to send your contract manufacturer? More specifically, which formats should you be sending them the files in.

The worst thing to see in a request for a quote (RFQ) package from a prospective client is to see all of the data attached in the email. This can mean one email with 20 different attachments. Please do not do this. It is annoying and tedious to organize all of this for you.

So, let’s break down what a CM would expect to receive and the formats that work for them.

To start, think about what you will be sending your CM. I suggest you check out this blog about what you should add. But to quickly go over it, you need to add the 3D CAD files, 2D files, BOM, schematics, Gerber files, product introduction, and some more.

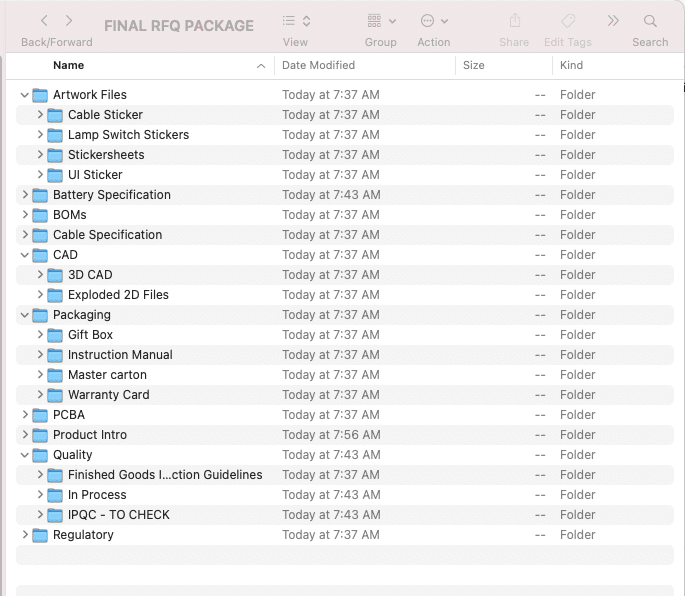

Let’s look at the process from the very start and see how we can organize everything. Whether you are using Google Drive or your personal computer, make sure that you use folders to hold all of your data instead of just one big blog of documents. Let’s look at an example I received from a client for the RFQ process.

As you can tell, there are multiple folders and within those folders are sub-folders and so on. All of the relevant information for us to provide a quote is here for our use.

Let’s dive in to see what these mean in more detail in alphabetical order. Remember, this is a specific example. Your RFQ might have more or less info, documents, and data.

Relevant Information Breakdown

There is one folder called battery specification. The documents here go into detail about the voltage, charge current, cell weight, dimensions, and other parameters. There is a reference battery with a manufacturing part number (MPN), but we also had the flexibility to find an alternative battery as well that was more cost-effective. However, the detailed spec sheet made it very clear the battery we needed to source from an alternative supplier.

Another folder is BOMs. There are just the electrical and mechanical BOMs. If you are looking for a quote, you can send them an Excel file if you currently do not use any BOM software. You can also check out this article to see what to include in the BOM.

In the CAD file or drawings file, you should have two additional folders. One for 3D CAD and one for 2D files. The 3D CAD should be sent in STEP format and just PDF for the 2D files.

The packaging is meant to get a full quote for your product. For some reason, the packaging is usually forgotten about and the clients usually don’t budget this in. When sending the files for packaging, you can send them in Ai or EPS formats and include the PDF as well.

The PCBA should also be in its own folder because you will have a few extra folders in here as well. These extra folders will include Gerber files, a schematic diagram, and some pictures of what the PCB looks like for the layout.

Product introduction is quite simple. This is just explaining the product and the company income detail. I always have appreciated this because I like to know who we are working with.

If you have quality standards then you should always add these. In this example, it’s broken down into IQC (incoming quality control), In-Process and Finished Goods. In each of these folders, there are additional documents stating what to check and each area. These can be word documents or excels.

Lastly, we have regulatory. This just states the marking requirements for the product. Such as what marks you need for the product and packaging. This will include CE, FCC, ICES, Prop65, Made In China, ROHS, and more.

Conclusion

Files and folders are great, but this not very efficient. OpenBOM gives you much more. Check our coming zip file export feature at OpenBOM.

In one of our next blogs, we will demonstrate how to implement the best strategy of structuring data to send it a contractor using OpenBOM.

OpenBOM believes engineering, supply chain, and manufacturing teams should be able to seamlessly manage their parts, vendors, bill of materials, purchase orders, and change orders. All BOM, engineering, and manufacturing information are stored in the cloud which you can share with your team, contractors, suppliers, or anyone else that has access to your account. OpenBOM keeps everyone on the same BOM while providing you with the tools to streamline your development to production & scale up operations.

Register for FREE to create your OpenBOM account and reach out to us via support @ openbom dot com if you have any questions.

Best,

Jared Haw

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.