If you’re in manufacturing, you know the importance of agile procurement planning. You need to be able to change plans quickly in order to stay ahead of your competition. However, many companies are still using Excel to plan their procurements. While Excels can be useful for some things, they are not good for agile procurement planning workflows.

In this blog post, we’ll explain why Excels are not good for agile procurement planning and what you can use instead.

Bad habits die hard

In my earlier blogs this week, I made some analyses and brought examples of how engineers and manufacturing organizations are sliding towards the usage of Excels and other spreadsheets to get some immediate short time wins.

Engineers are not responsible for data management strategy and are not supposed to deal with laying down the foundation of the digital process. Engineers by nature are “problem solvers”. They are looking for an easy way (for them) to kick off the process of planning and they do it by exporting information to a spreadsheet. The problems are coming later and include many challenges and damages to business outcomes. Teams are not staying on the same page managing BOM structure using Excel. The data is lost and the engineering bill is disconnected from the manufacturing bill of materials, not providing information for supply chain efforts and procurement.

Dumping data into Excel feels natural while thinking about digital technologies and product lifecycle management feels hard. Most legacy PDM and PLM systems are like going back to 1995 or (let’s be fair) to the middle of the 2000s. They require IT support and implementation services. They cost money and the majority of them are not user-friendly. It is very hard to compete with something that normally doesn’t require any cost. Free is a magic word, but it also comes as a state of independence from IT and budgetary constraints. It is extremely important for everyone (especially engineers) to come to the point when they can say “I completed my job” and push the ball on someone else’s side.

Check these two articles to understand better the mechanics of these organizational processes.

- Why Poor BOM Management Slows Down Your Digital Transformation Efforts

- From Email Attachments and Shared Excel Files To Information Flow And Digital Transformation

Agile Processes and Spreadsheet Time Bomb

Everything seems to be ok for the first shot. Engineers are dumping their CAD data into Excel and sending this data downstream. From that moment, engineers are disconnected from the data and other people in the organization (eg. purchasing planner and supply chain) are in charge to translate these Excel reports into the actions to make orders to buy raw materials and to turn these Excel bills of materials into purchasing planning and eventually assembly finished products that can be shipped to the customers.

The process for procurement teams to follow might require some validation with engineers and also filling some incomplete data gaps. The excels are going back with comments and questions and then engineers realized that some mistakes were made and require some additional changes. Meantime, procurement planners already filled those Excels with some initial data about suppliers and specific procurement information. And this is where the “fun” begins. Multiple Excels, multiple emails, and multiple versions of the data extracted from CAD systems with changes. This is the result of what the “we just export data to Excel” strategy is becoming after some time. To make it even worst, some of these Excel reports can be sent to contract manufacturers and also require some changes and adjustments.

The scenario I described above is only the beginning of the nightmare. Most engineering and manufacturing teams today have a desire to work agile and manage their processes interactively – creating a first design prototype, getting to order LLI (long lead items), and then continuing the work on the design until the full release and final product structure will become available to finish orders. But the management of these agile processes goes completely wrong with any Excel/Email/Share workflows.

OpenBOM Agile Procurement Collaboration Flow

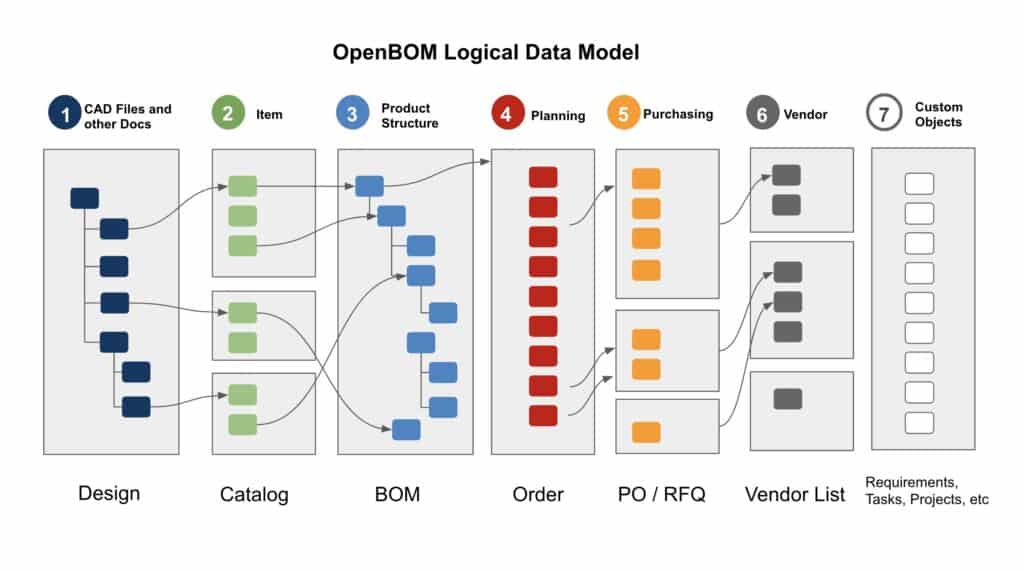

The revolutionary online services OpenBOM offers make a big difference in the processes I just described above. OpenBOM provides a fully integrated information flow that connects data and people. Here are three pieces of this information flow.

- OpenBOM CAD Add-in automatically extracts design and turns it into a structured product data structure including all information needed in BOMs with all CAD file attachments including neutral geometry in STEP, DXF, and DWG formats. This product structure stays in sync with all the changes done in CAD, so everything is updating smoothly as your engineers will continue to make changes.

- The team responsible for procurement and purchasing can work collaboratively and independently at the same time to manage all information about vendors, purchasing process, and suppliers’ relationships to define everything needed to make the planning and ordering process go smoothly.

- OpenBOM real-time collaboration and instant data sharing allow both teams to have simultaneous access to the information and perform changes as they are making progress with design changes and the procurement planning process. OpenBOM captures changes and performs history tracking to ensure nothing is lost and later available for traceability of changes.

In the picture below you can see the diagram shows how all information is connected in the integrated information flow.

Check OpenBOM documentation for more information. The greatest outcome of OpenBOM collaboration and data management is that it eliminates siloed data in multiple teams (engineering and procurement) and allows both teams to work together while performing their own tasks.

Conclusion

OpenBOM web service provides a set of data management and collaboration tools to eliminate data silos and support an integrated information flow between engineers and procurement. Such a flow of information allows a company to adopt agile product development methods to organize product development and manufacturing processes, support collaboration, and eliminate potential mistakes. OpenBOM also provides a full traceability record of changes that are absolutely needed for regulated industries. The most important result is speed – one of the biggest competitive advantages in modern manufacturing.

However, bad habits die hard and your organization needs support to disconnect from old Excel-driven processes to adopt new digital tools. Keep in mind, that it won’t happen automatically. The changes are hard for everyone. Therefore OpenBOM provides dedicated tailored support for companies to onboard OpenBOM services. Learn more here – OpenBOM Premium Onboarding Experience.

Want to learn more? Please contact us and schedule an OpenBOM Demo online.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.