The manufacturing industry is highly distributed these days and therefore requires tools capable of creating and sharing a single source of truth about the product they develop with all relevant stakeholders – engineers, managers, contractors, partners, and suppliers.

Excel (or other forms of spreadsheets) are super popular in this environment, but as we learned working with thousands of users and customers, these spreadsheets are one of the most complex and unreliable pieces of information you can use to manage a single source of information about a product. The data is messed up, duplicated, lost, which leads to mistakes, delays and additional cost.

OpenBOM global and distributed data management technology allows you to create a BOM, collaborate with your team, and share the BOM (product structure) with everyone. After all, the creation of the Bill of Materials and all related data is a very complex process.

I want to focus on four customer stories from the automotive industry – Tomcar, Gaius Automotive, Questum, and Nandan. All these companies are building vehicles or part of vehicles. There are 3 important things that is common for all these stories we made about these companies:

- Easy way to create the data – manually or collaboratives.

- Organizing a single source of information to eliminate duplications

- Share the data with all contractors, partners, and suppliers

Check out the stories below:

Tomcar

Jonathan Drori is the US company lead engineer and is part of the team responsible for the Tomcar series of vehicles.“I absolutely love that OpenBOM lets me share accurate, complete BOMs with vendors, partners, customers, my colleagues in Israel, and so many more.”, says Jonathan. “It is great for my team and great for the company.”

Jonathan brought OpenBOM to Tomcar to improve and formalize the agreements the company has with manufacturing partners. “Simply put, before OpenBOM, we did not have a final BOM that was accurate or easy to share”, he says, “We needed a full product BOM which OpenBOM delivered!”

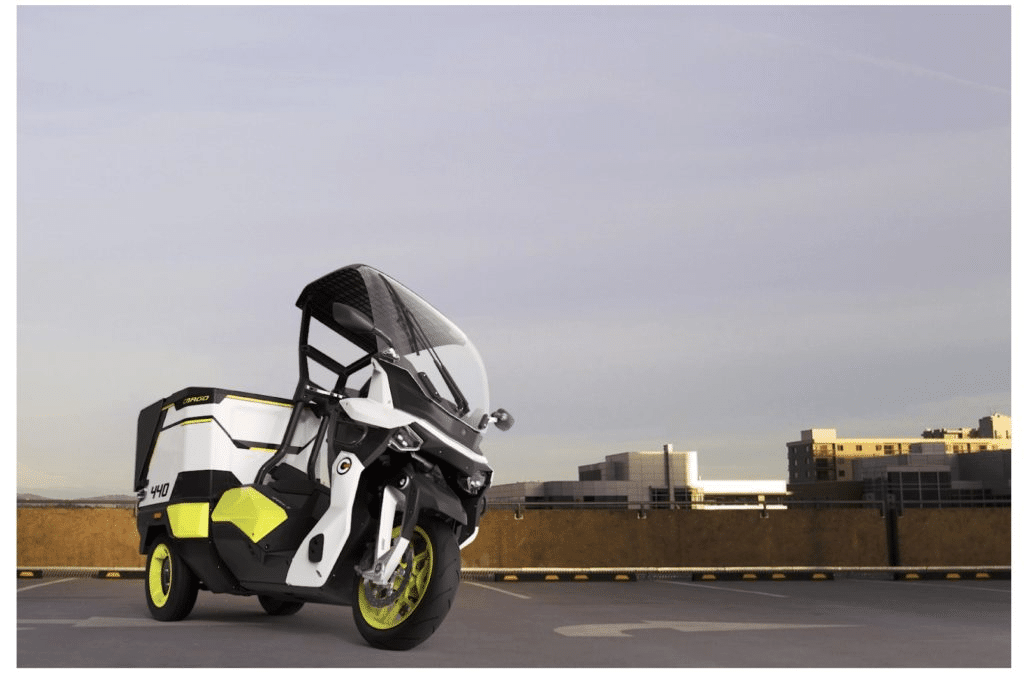

Gaius Automotive

The Gaius Engineers and planners create BOMs in OpenBOM which are shared with the team using specific methods and Views; OpenBOM automatically applies the rules described above so each team member gets that personal view. OpenBOM also controls who and what can or cannot be seen by others on the team.

“For example”, says Chen, “Our design verification BOM may be different than the next evolution of the design coming along, we use OpenBOM to manage that design maturity and who sees the BOM at which phase of the design process.”

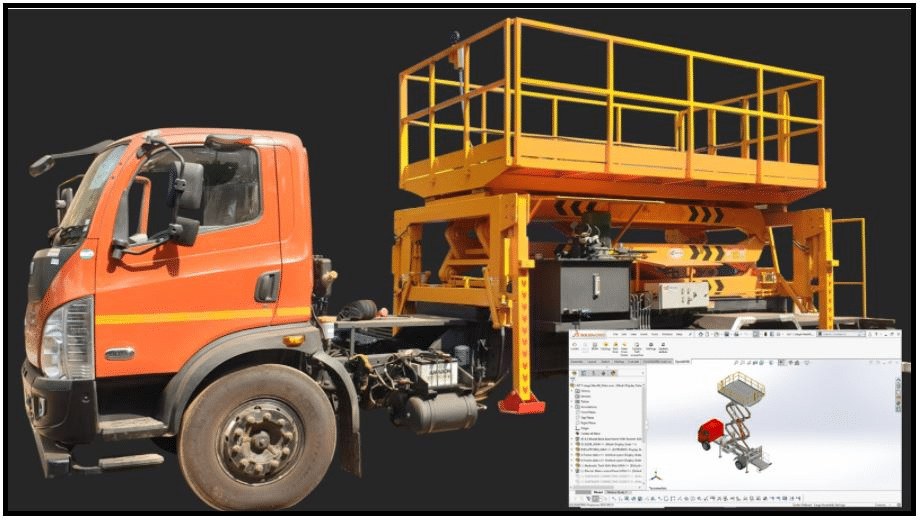

Questum Mobile

Alfonso went into specific detail about how Atmovum uses the OpenBOM Catalog structure to organize items by category, a Catalog for each category; 1) Design, 2) Components, 3) Commercial/buy, 4) Hardware/fasteners/clamps/washers, and 5) Assemblies.

According to Alfonso, “our BOMs are much faster to produce, are more reliable, and afford much more reuse than the excel-based process.”

Elias explains, “we have a lot of existing BOMs which we can easily leverage. Our catalog structure helps us build BOMs more reliably and easily share major (functional) sub-assemblies like an entire power train between BOMs. Just enter the part number for a power-train sub-assembly and the entire structure flows into the new BOM.”

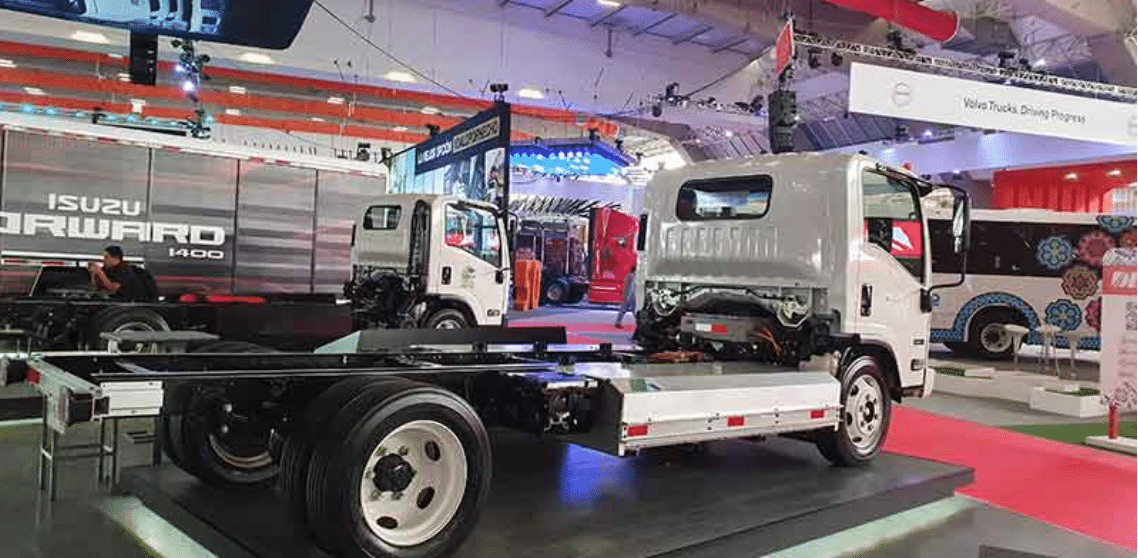

Nandan

“We rely on the OpenBOM CAD integrations to extract, organize and maintain the product structure and design intent as information flows to a single multi-discipline BOM,” says Dhanesh. We worked closely with Neel SMARTEC to develop and implement the process.

The Nandan design team brings BOM data from several CAD tools and disciplines using OpenBOM’s unique ability to merge and display multi-level BOMs with a variety of individual user-defined properties. BOMs need not have all the same columns or properties to be visualized in a single view.

The OpenBOM visual dashboard and highly configurable landing page and BOM grid allow individuals within their organization to personalize the View that is best suited for the task.

Conclusion

OpenBOM’s robust data management platform makes it easy to build a full product structure, from multiple sources – CAD systems, excels spreadsheets, bring relevant connected information from catalogs with items, supplies, and contractors, and use OpenBOM user-defined views to share data in role-based forms.

For a more hands-on look, REGISTER FOR FREE and check out what OpenBOM can do for you.

Best, Oleg

Join our newsletter to receive a weekly portion of news, articles, and tips about OpenBOM and our community.